System and method for accurately controlling dosage of external carbon source

A technology of precise control and dosage, applied in chemical instruments and methods, solid separation, grain processing, etc., can solve the problems of inaccurate feeding and difference in the amount of feeding, so as to improve the accuracy of feeding, strong practicability, and ensure feeding. The effect of consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

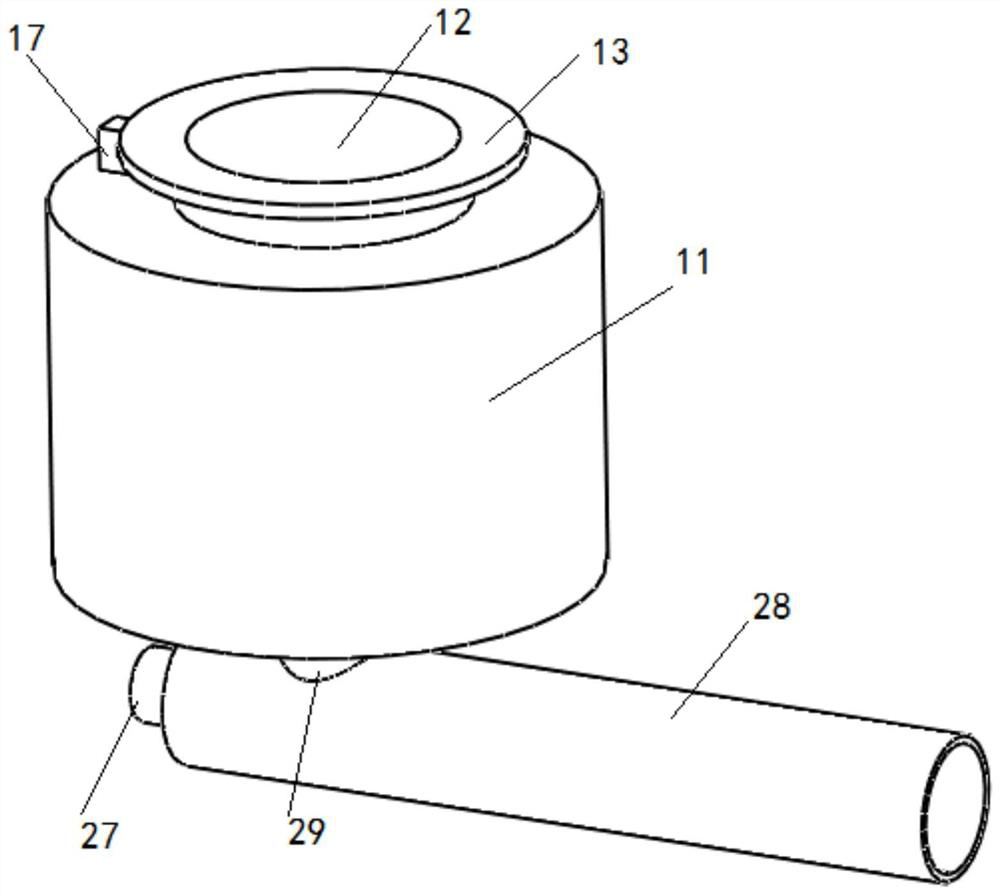

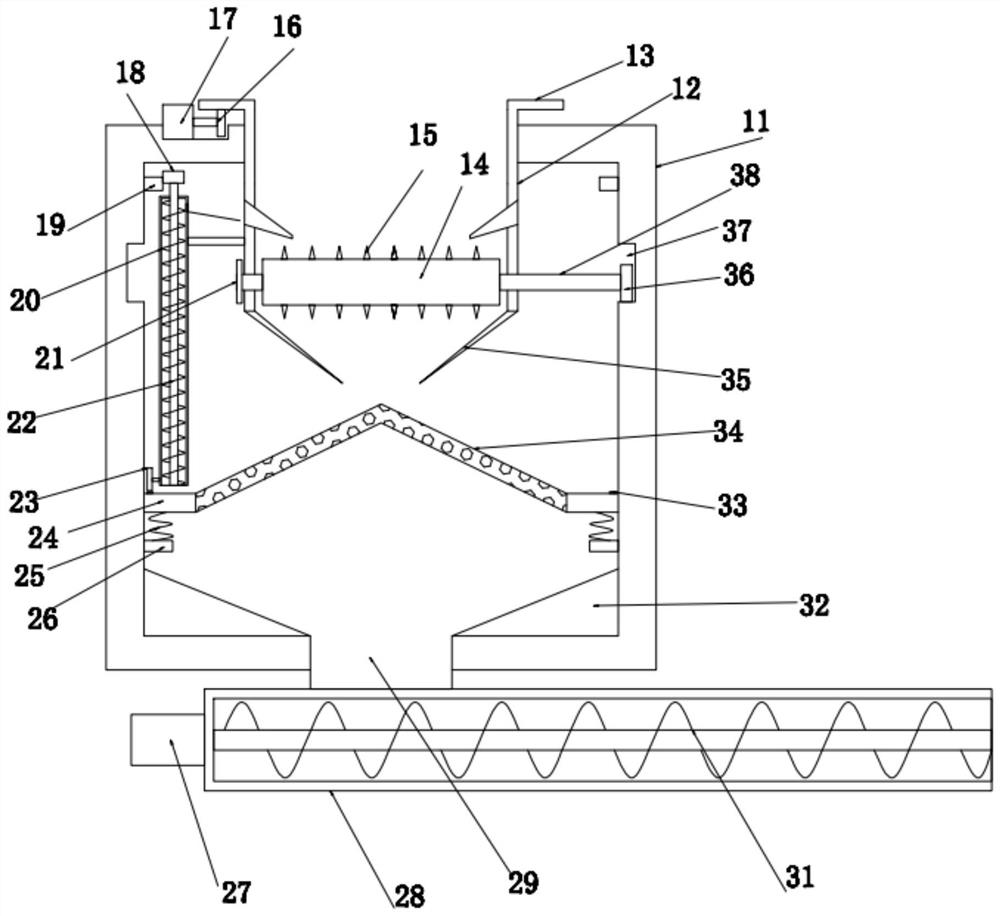

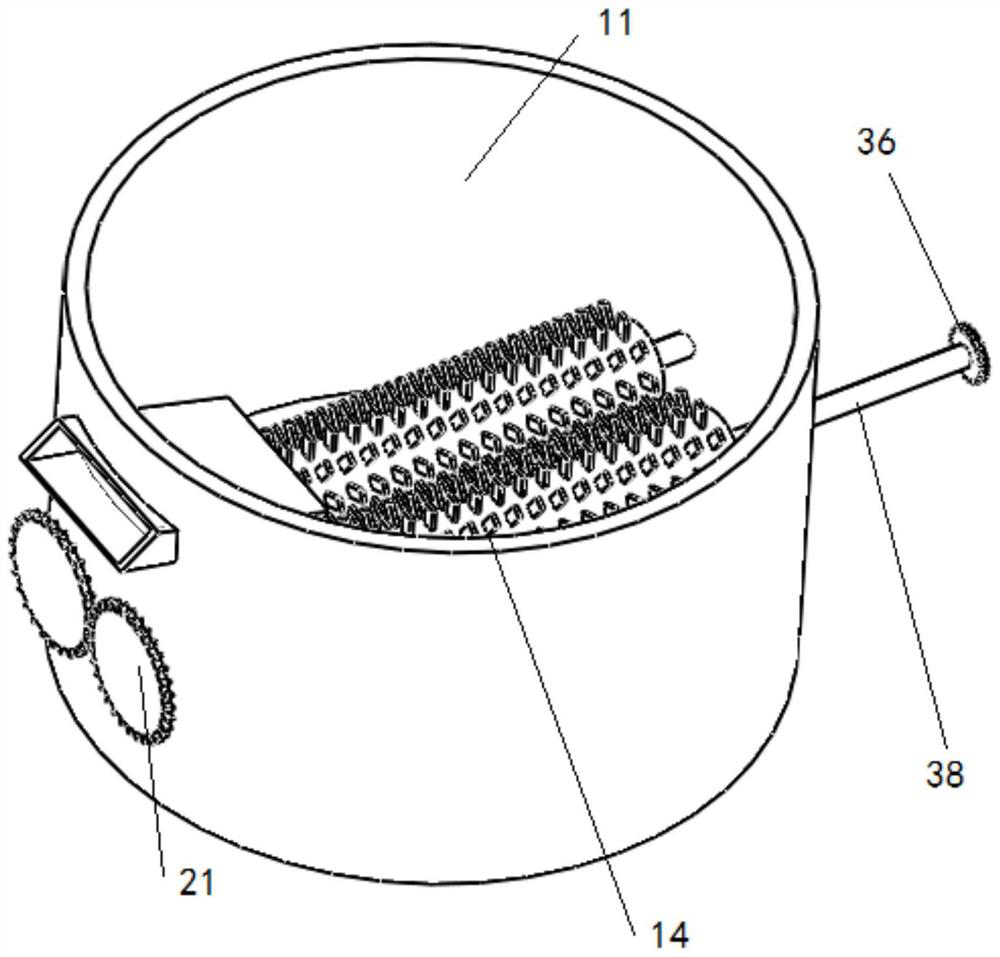

[0022] see Figure 1-Figure 4 , In the embodiment of the present invention, a precise control of the dosage of the external carbon source includes a pulverizing box 11 and a pulverizing component arranged inside the pulverizing component for pulverizing coal. Screening assembly, the bottom middle of the crushing box 11 is provided with a discharge port 29 for discharging, and the lower end of the discharge port 29 is connected to a horizontal pushing cylinder 28 for conveying coal. The horizontal pushing cylinder 28 Inside is provided with a pushing auger 31 for horizontally conveying coal, and the left end of the pushing auger 31 is connected to a feeding motor 27 for driving it to rotate. In actual use, the coal is fed into the crushing box 11, Under the action of the pulverizing component, the coal will be pulverized, and the qualified coal will pass through the screening component and enter the horizontal pushing barrel 28 for feeding. This feeding method ensures the size ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com