Cement grinding and screening device

A grinding device and cement technology, which is applied in the field of cement, can solve the problems of unavoidable cement accumulation inside the screen holes, etc., and achieve the effects of being easy to be used, improving the uniformity of crushing, and increasing the probability of rebound

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

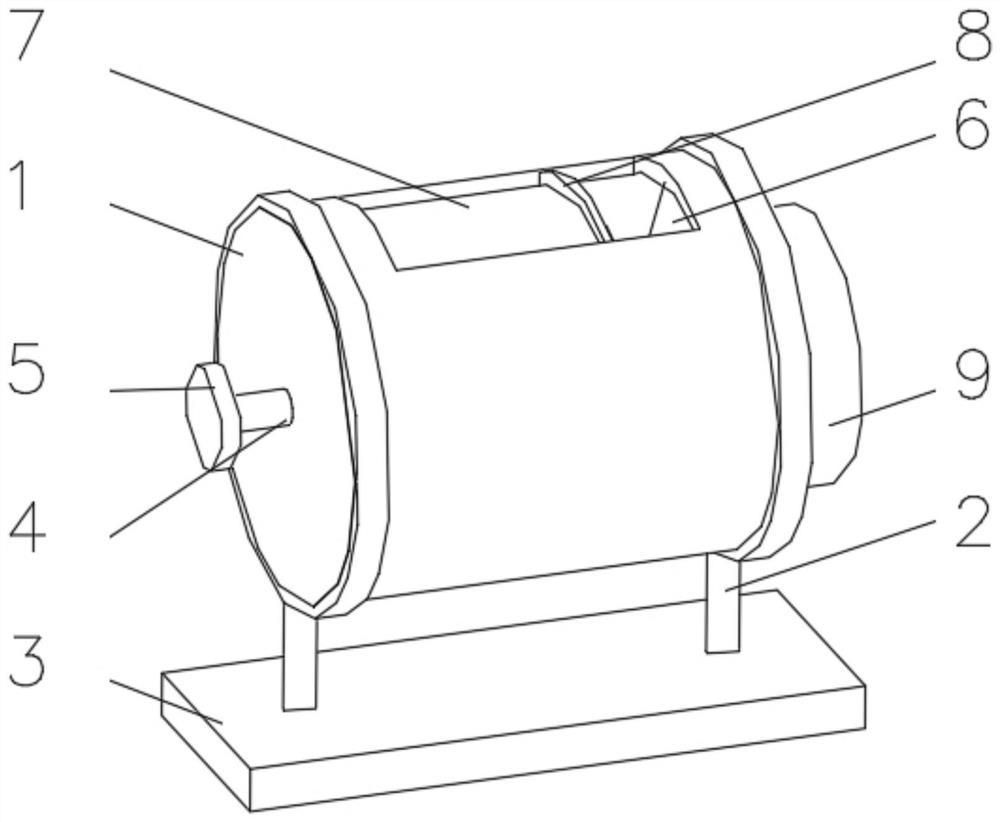

[0032] see Figure 1-4 , the present invention provides a technical solution: a cement grinding and sifting device, including a processing frame 1, a support frame 2 is symmetrically installed on the bottom of the processing frame 1, a base 3 is installed on the end of the support frame 2 away from the processing frame 1, and the processing frame One side of 1 is connected with a pusher tube 4, and the end of the pusher tube 4 away from the processing frame 1 is equipped with a dustproof cover 5, and the side of the processing frame 1 away from the support frame 2 is provided with a feed port 6, and the inner wall of the processing frame 1 A sliding cover 7 is connected to a position close to the feed port 6, a handle 8 is installed on one side of the sliding cover 7, and a discharge port 9 is connected to the side of the processing frame 1 far away from the pushing pipe 4, and the inner wall of the processing frame 1 is close to the discharge port. A screen 10 is fixedly conn...

Embodiment 2

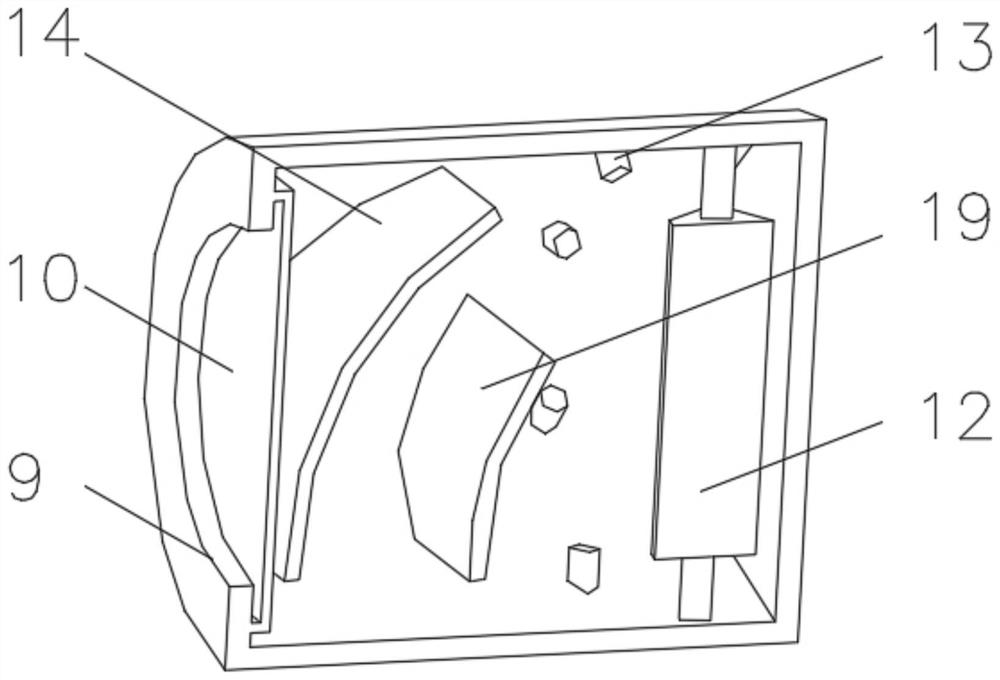

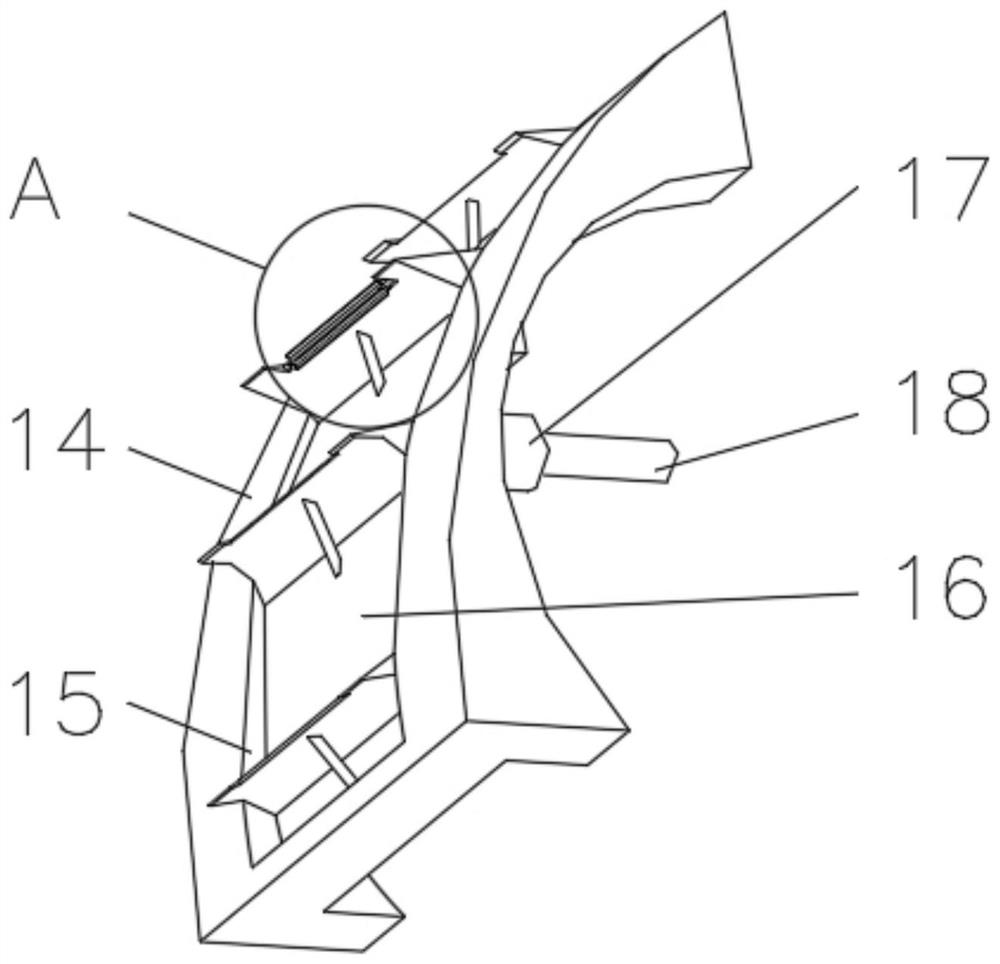

[0039] see Figure 1-5 , the present invention provides a kind of technical scheme: on the basis of embodiment one, the inner wall of processing frame 1 is equipped with grinding device 12, and grinding device 12 comprises grinding frame 121, and one side of grinding frame 121 is evenly equipped with semicircle frame 122, semicircle An elastic pull cord 123 is fixedly connected to the inner wall of the frame 122 , and blades 124 are evenly installed on the outside of the elastic pull cord 123 .

[0040] One side of the grinding frame 121 is fixedly connected with a rotating rod 125 , and the end of the rotating rod 125 away from the grinding frame 121 is equipped with a rotating motor 126 .

[0041] When in use, turn on the rotating motor 126 to drive the rotating rod 125 to rotate, and then drive the elastic pull cord 123 to drive the blade 124 to rotate. The blade 124 touches the cement for grinding and crushing. Through the installation of the grinding device, the rotating ...

Embodiment 3

[0043] see Figure 1-6 , the present invention provides a technical solution: on the basis of Embodiment 2, an elastic device 13 is installed on the inner wall of the processing frame 1 near the position of the grinding device 12, and the elastic device 13 includes a bottom frame 131, and one side of the bottom frame 131 is connected to the processing The frame 1 is fixedly connected, and the side of the bottom frame 131 away from the processing frame 1 is symmetrically installed with a limit block 132. The side of the bottom frame 131 close to the limit block 132 is fixedly connected with a spring 133, and the end of the spring 133 away from the bottom frame 131 is fixedly connected with a Curved push plate 134.

[0044] An arc-shaped baffle 19 is installed on the inner wall of the processing frame 1 close to the elastic device 13, and the arc-shaped baffle 19 is made of elastic material.

[0045] When in use, when the grinding device 12 is processing cement, the cement is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com