Wire sheath removing device for two ends of wire

A wire and wire sheathing technology, which is applied in the field of wire peeling devices at both ends of the wire, can solve problems such as low work efficiency, laborious operation, and troubles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

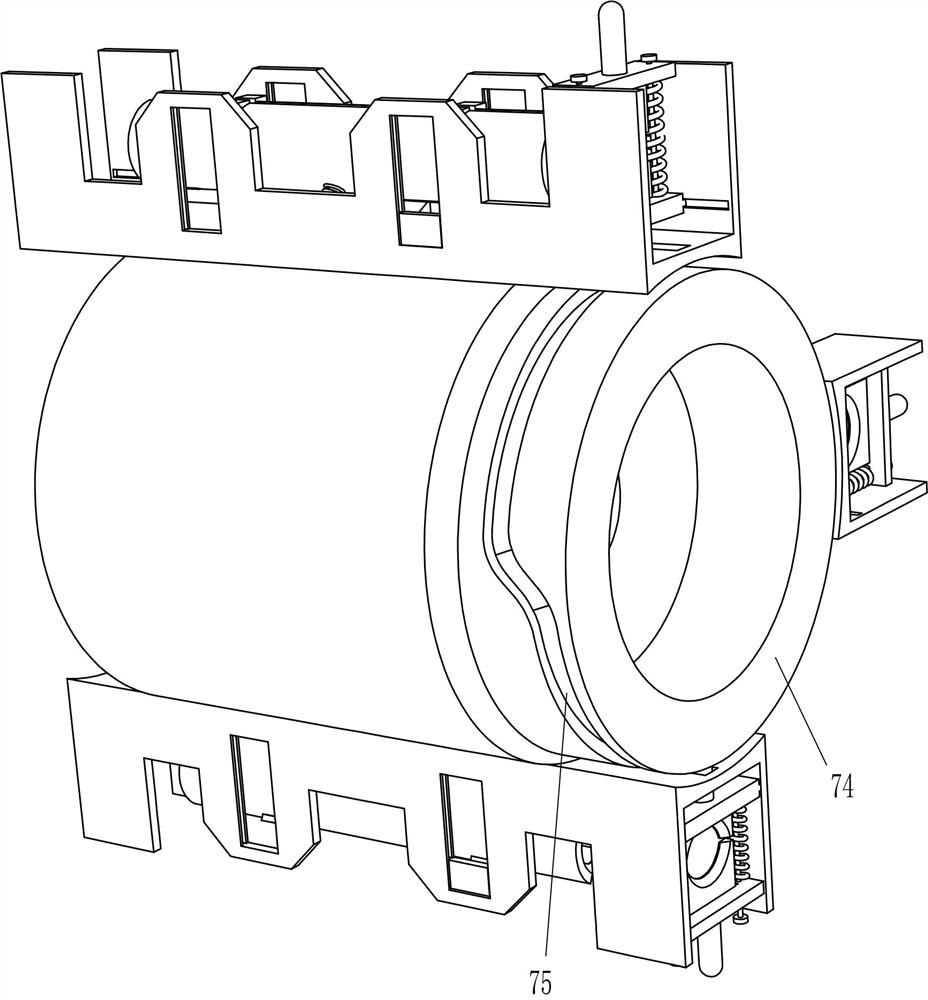

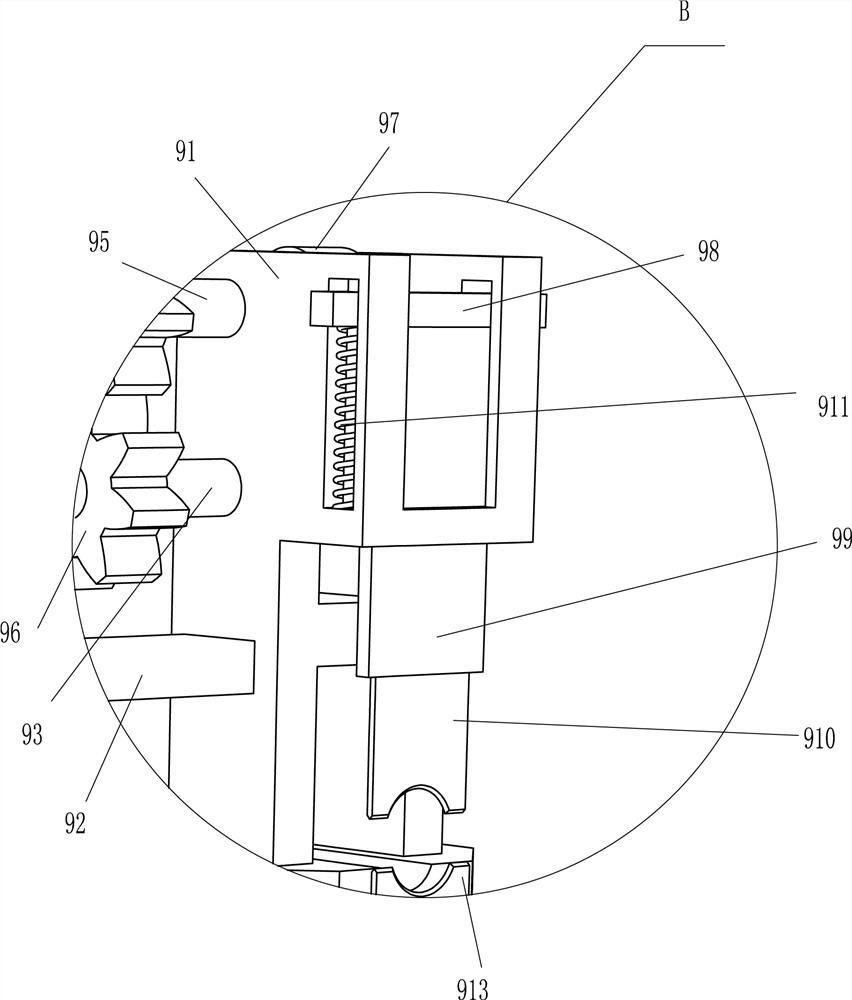

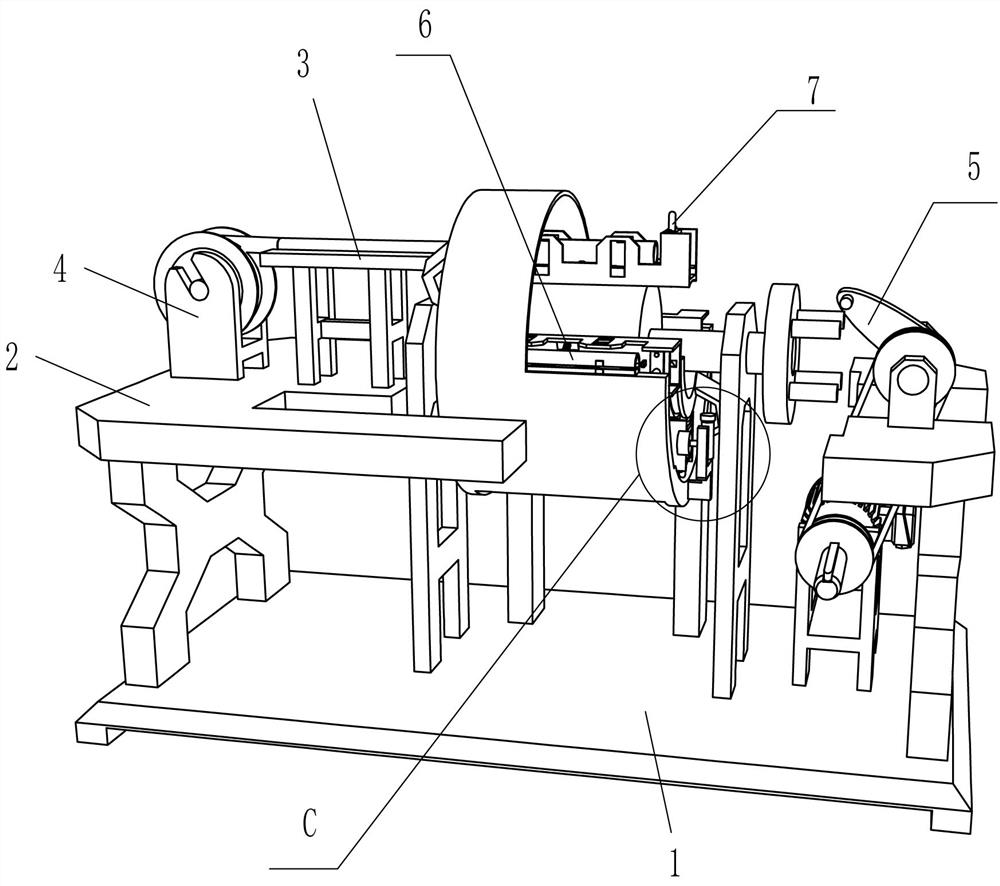

[0032] A device for stripping wire ends at both ends of an electric wire, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 with Figure 11 As shown, it includes a base 1, a workbench 2, a feeding table 3, a material rack 4, a rotating device 5, a clamping device 6 and a wire stripping device 7. The workbench 2 is fixed on the base 1, and the top left of the workbench 2 The feeding platform 3 is fixedly connected to the side, and the material rack 4 is fixedly connected to the left side of the top of the working table 2. The material rack 4 is located on the left side of the feeding table 3. A clamping device 6 is provided, and a stripping device 7 is provided between the rotating device 5 and the clamping device 6 .

[0033]The rotating device 5 includes a bracket 51, a motor 52, a first rotating shaft 53, a first vertical block 54, a second rotating shaft 55, a first transmission assembly 56, a first cam 57, a shift lever 58, a vertical plate 5...

Embodiment 2

[0041] On the basis of Example 1, such as figure 1 , Figure 7 , Figure 8 with Figure 9 As shown, a driving device 8 is also included, and the driving device 8 includes a first H-shaped frame 81, a fourth rotating shaft 82, a second transmission assembly 83, a missing gear 84, a second H-shaped frame 85, a fifth rotating shaft 86, a One full gear 87, the second vertical block 88, the sixth rotating shaft 89, the third transmission assembly 810, the feeding column 811, the third vertical block 812, the seventh rotating shaft 813 and the fourth transmission assembly 814, the left front part of the top of the base 1 A first H-shaped frame 81 is fixedly connected, and the upper part of the first H-shaped frame 81 is rotatably provided with a fourth rotating shaft 82 , and a second transmission assembly 83 is connected between the middle circumferential direction of the fourth rotating shaft 82 and the front circumferential direction of the first rotating shaft 53 , The second...

Embodiment 3

[0046] On the basis of embodiment 1 and embodiment 2, such as figure 1 , figure 2 with Figure 10 As shown, it also includes a third H-shaped frame 10, a buffer spring 11 and a discharge hopper 12. The middle of the top of the base 1 is symmetrically provided with a third H-shaped frame 10, and both ends of the top of the third H-shaped frame 10 are fixedly connected with a buffer A discharge hopper 12 is affixed between the spring 11 and the tail ends of the four buffer springs 11 .

[0047] Also include special-shaped plate 13, contact cylinder 14 and sponge block 15, the bottom of fixed cylinder 72 left and right sides is all fixedly connected with special-shaped plate 13, and the top rear side of special-shaped plate 13 is rotated to be provided with contact cylinder 14, and the inner surface of special-shaped plate 13 A sponge block 15 is fixedly connected to the front side of the upper part.

[0048] When the peeling of the wire ends at the two ends of the electric w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com