Visual detection mechanism for crack of solar cell panel

A technology for solar panels and testing institutions, applied in measuring devices, optical testing for flaws/defects, instruments, etc., can solve problems such as missed detection efficiency and slow detection speed, improve production and quality, reduce labor costs, and improve The effect of detection speed and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

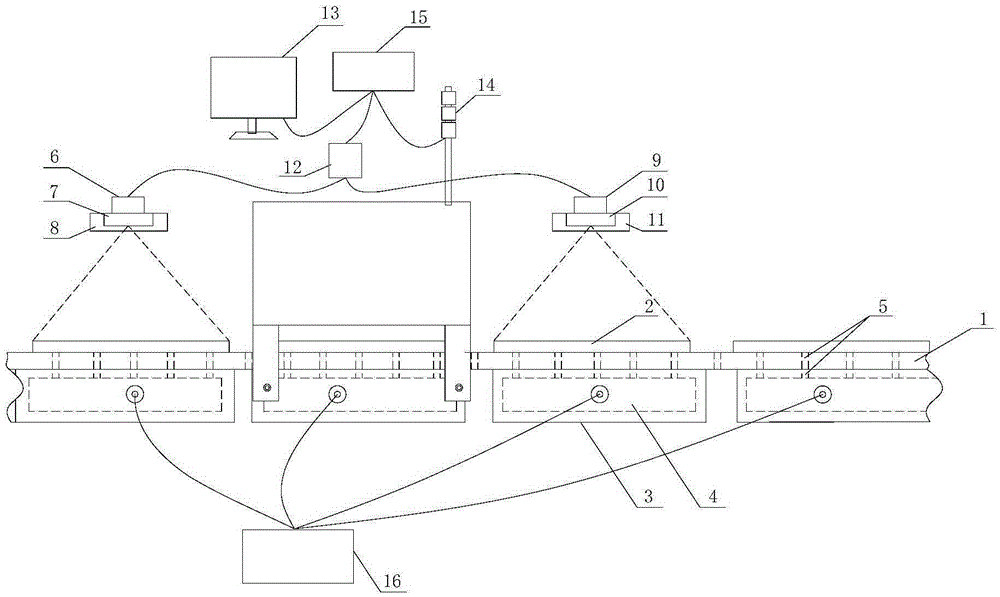

[0015] The present invention will be described in detail in conjunction with accompanying drawing now. This figure is a simplified schematic diagram only illustrating the basic structure of the present invention in a schematic manner, so it only shows the components relevant to the present invention.

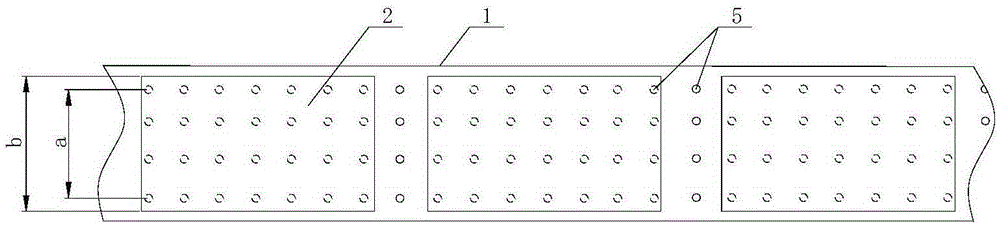

[0016] Such as Figure 1-2 As shown, a visual solar cell panel fragmentation detection mechanism of the present invention includes a conveyor belt 1, a vacuum adsorption assembly and a visual detection assembly. The solar cell panels 2 are placed on the conveyor belt 1 at equal intervals, and the vacuum adsorption assembly includes several adsorption plates. 3. The adsorption plate 3 is located under the conveyor belt 1. There is a cavity 4 inside the adsorption plate 3. The interior of the cavity 4 is connected to the negative pressure system 16. The upper end of the adsorption plate 3 has a plurality of through holes connecting the cavity 4 and the outside. 5. The conveyor be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com