Rotary blank-feeding linear automatic bottle blowing machine

A rotary blow molding machine technology, applied in the field of plastic machinery, can solve the problems of large energy loss, affecting the quality of formed bottles, and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

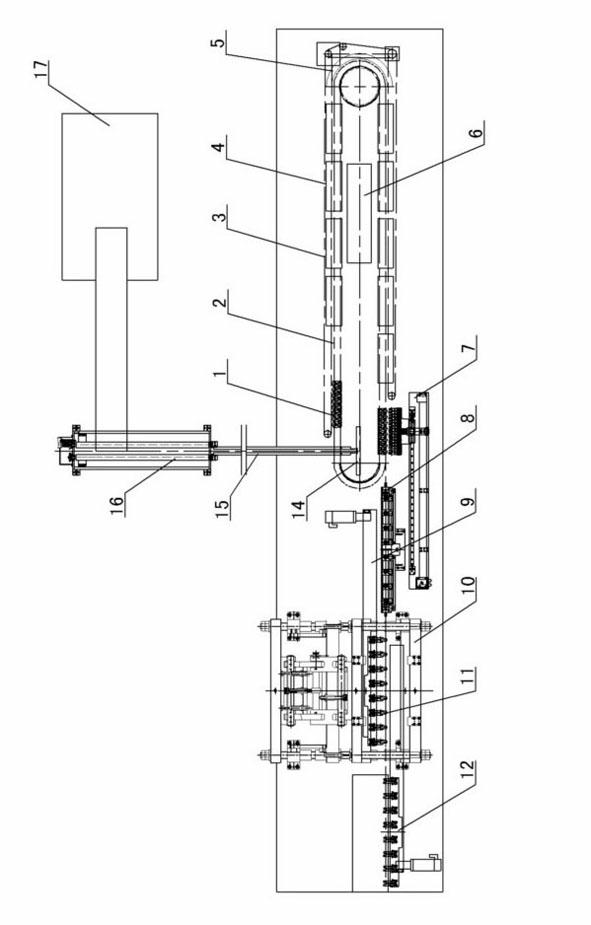

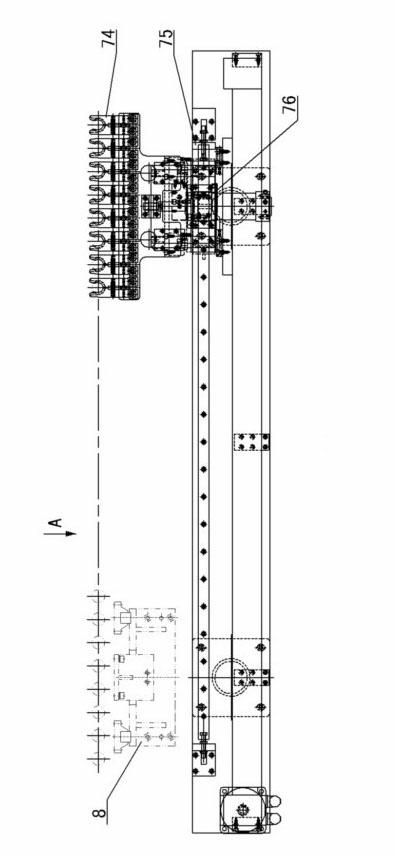

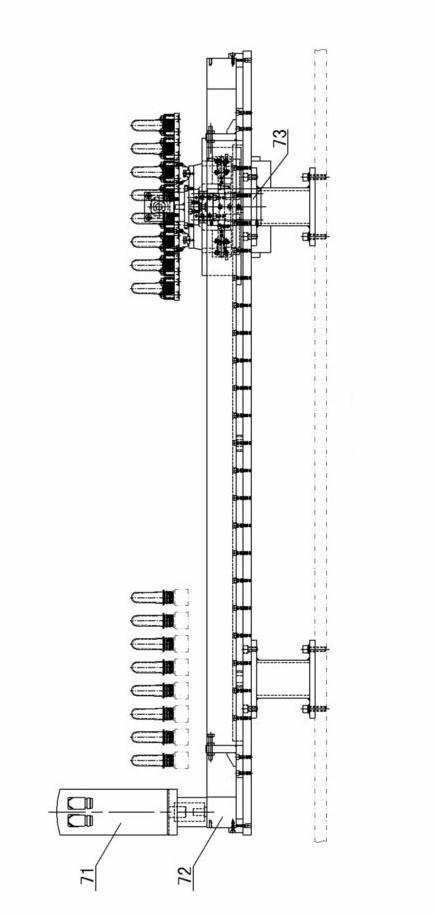

[0020] The present invention relates to a kind of rotary type preform linear automatic bottle blowing machine, such as Figure 1-Figure 10As shown, it includes a heater and a stretch-blow machine. The heater has a preform mechanism 14, and the preform mechanism has an embryo rack 15, a single-slide discharger 16 and a conveyor 17. There is a take-off mechanism between the heater and the stretch-blow machine. Embryo mechanism 7, relay station 8 and embryo feeding mechanism 9, described heater comprises accompanying jig 1, revolving transmission 2, rotation transmission 3, heating light box 4, conveying guide rail 5 and exhaust device 6, and described drawing and blowing machine comprises combined Die mechanism 10, sealing stretching 11 and bottle taking mechanism 12, it is characterized in that described embryo taking mechanism 7 comprises servo motor 71, embryo electric cylinder 72, lifting cylinder 73, embryo taking manipulator 74, embryo linear guide rail 75 and advance and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com