Oil sunflower floral leaf wring-dropping apparatus

A technique of mosaic and oil sunflower, applied in the field of oil sunflower mosaic and leaf twisting equipment, can solve the problems of palm injury, sunflower seeds falling off and waste, etc., and achieve the effect of easy falling off and convenient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

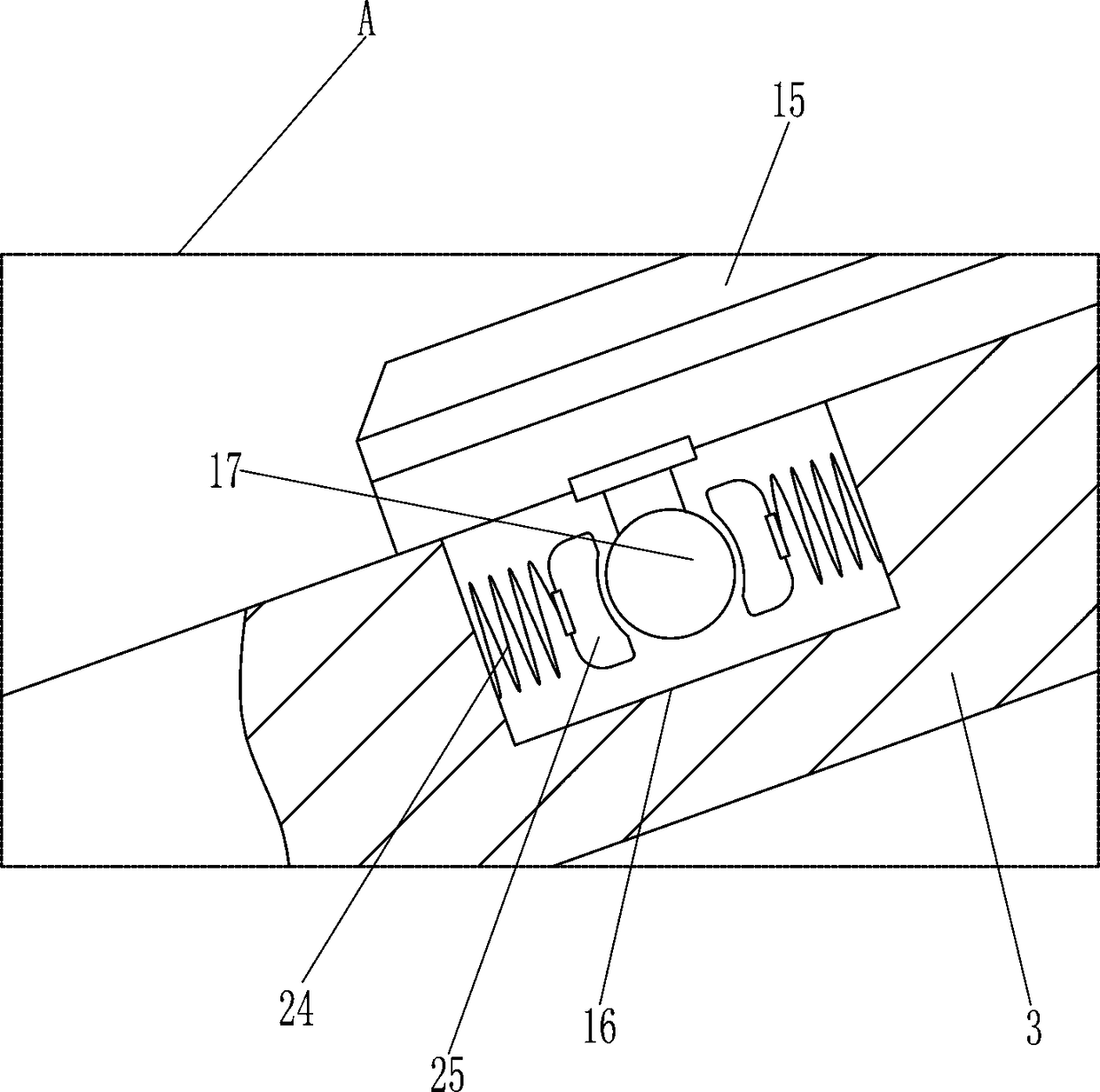

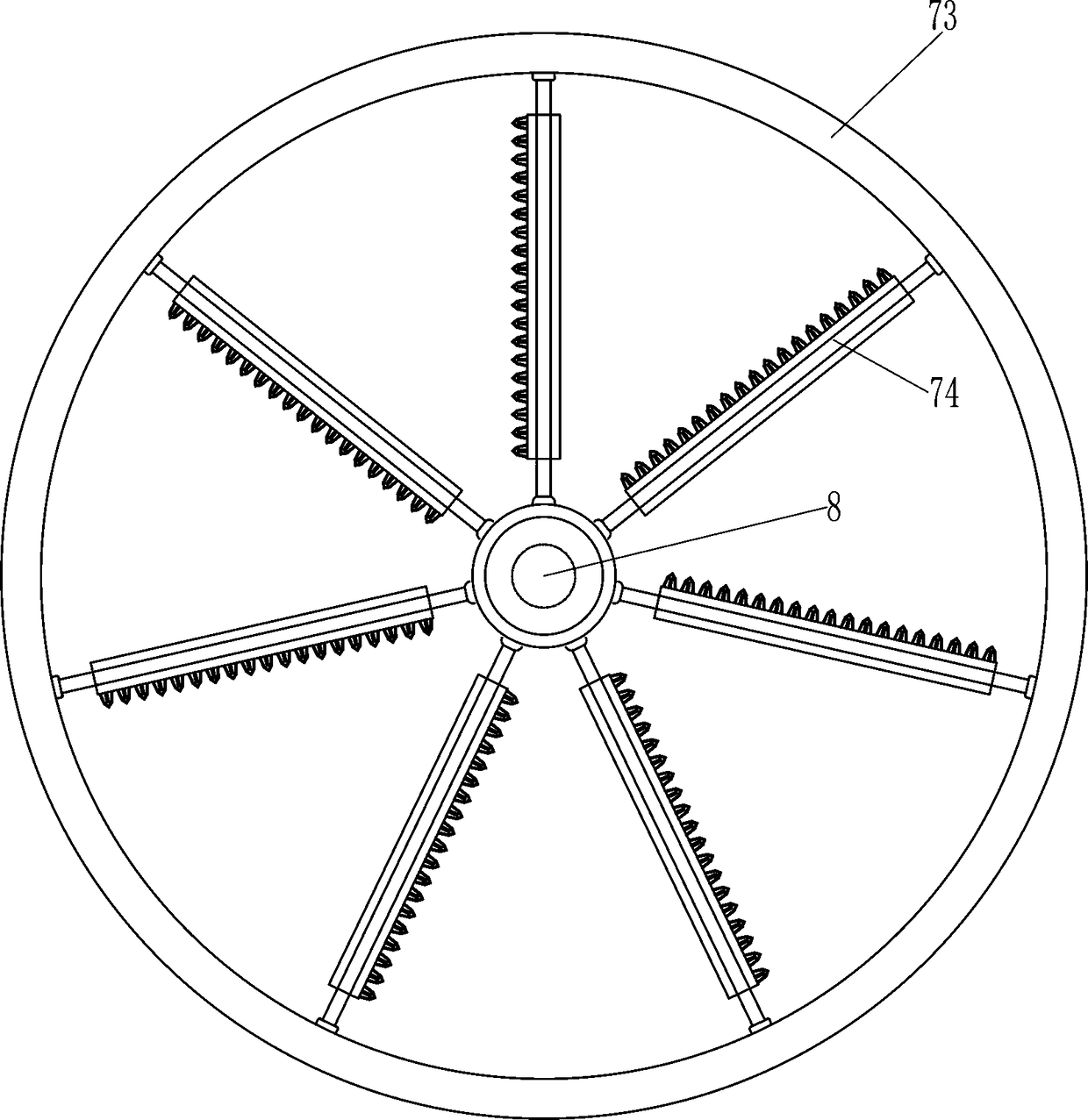

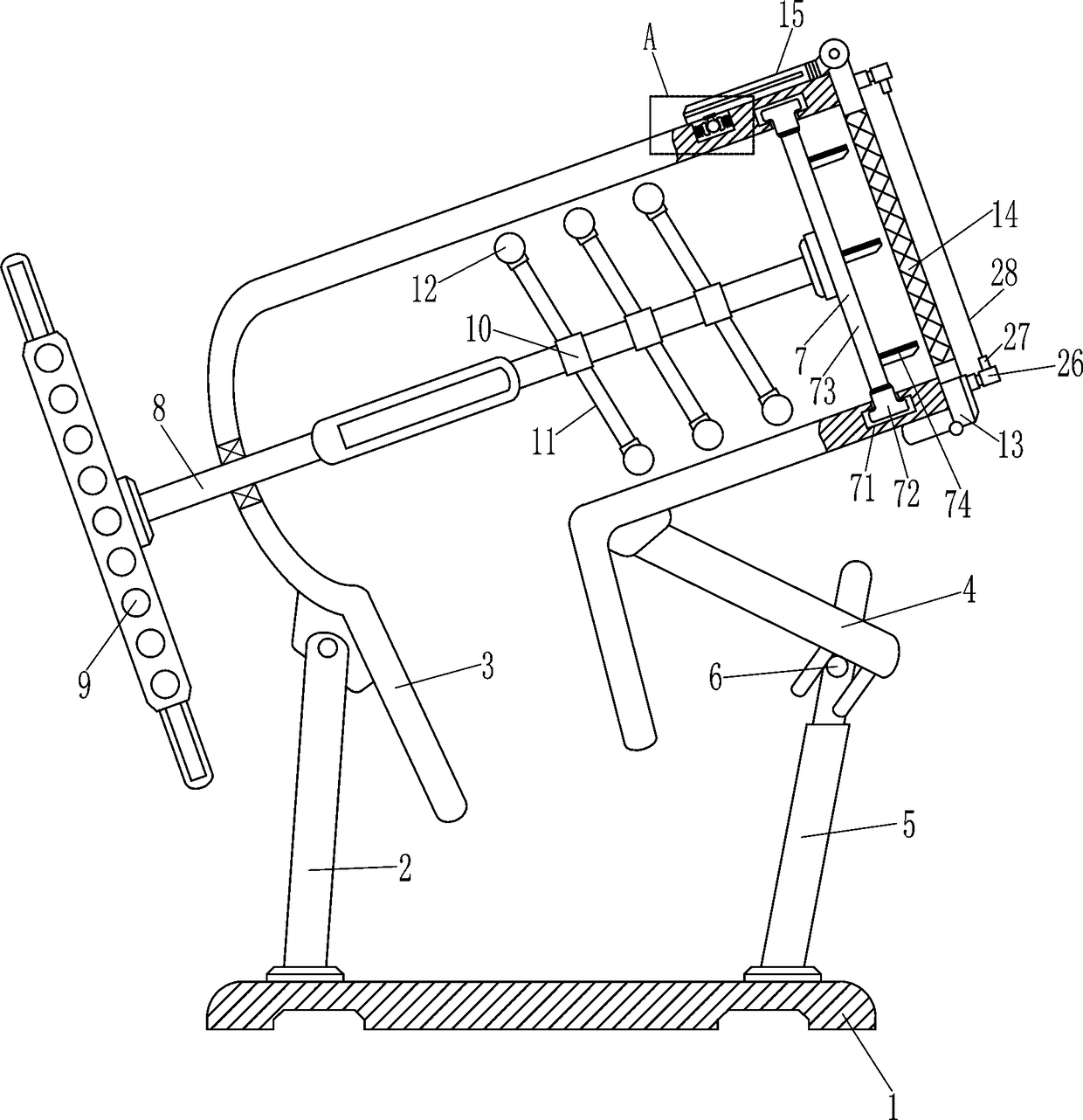

[0022] A kind of oil sunflower leaf wringing off equipment, such as Figure 1-4 As shown, it includes a base 1, a first support rod 2, a frame body 3, a limit rod 4, a first telescopic rod 5, a push rod 6, a winch device 7, a rotating shaft 8, a runner 9, a mounting block 10, a connection Rod 11, scraper ball 12, hinge 13, screen plate 14, connecting plate 15 and fixed rod 17, the upper left part of the base 1 is connected with the first support rod 2, and the upper part of the first support rod 2 is rotatably connected with the frame body 3 The right part of the lower side of the frame body 3 is connected with the limit rod 4, the upper right part of the base 1 is connected with the first telescopic rod 5, the upper front side of the first telescopic rod 5 is connected with the push rod 6, and the lower side of the right part of the limit rod 4 is connected with the The push rod 6 contacts, and the left part of the frame body 3 is rotatably provided with a rotating shaft 8, t...

Embodiment 2

[0024] A kind of oil sunflower leaf wringing off equipment, such as Figure 1-4 As shown, it includes a base 1, a first support rod 2, a frame body 3, a limit rod 4, a first telescopic rod 5, a push rod 6, a winch device 7, a rotating shaft 8, a runner 9, a mounting block 10, a connection Rod 11, scraper ball 12, hinge 13, mesh plate 14, connecting plate 15 and fixed rod 17, the upper left part of the base 1 is connected with the first support rod 2, and the upper part of the first support rod 2 is rotatably connected with the frame body 3 The right part of the lower side of the frame body 3 is connected with the limit rod 4, the upper right part of the base 1 is connected with the first telescopic rod 5, the upper front side of the first telescopic rod 5 is connected with the push rod 6, and the lower side of the right part of the limit rod 4 is connected with the The push rod 6 contacts, and the left part of the frame body 3 is rotatably provided with a rotating shaft 8, the...

Embodiment 3

[0027] A kind of oil sunflower leaf wringing off equipment, such as Figure 1-4As shown, it includes a base 1, a first support rod 2, a frame body 3, a limit rod 4, a first telescopic rod 5, a push rod 6, a winch device 7, a rotating shaft 8, a runner 9, a mounting block 10, a connection Rod 11, scraper ball 12, hinge 13, screen plate 14, connecting plate 15 and fixed rod 17, the upper left part of the base 1 is connected with the first support rod 2, and the upper part of the first support rod 2 is rotatably connected with the frame body 3 The right part of the lower side of the frame body 3 is connected with the limit rod 4, the upper right part of the base 1 is connected with the first telescopic rod 5, the upper front side of the first telescopic rod 5 is connected with the push rod 6, and the lower side of the right part of the limit rod 4 is connected with the The push rod 6 contacts, and the left part of the frame body 3 is rotatably provided with a rotating shaft 8, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com