Horizontal type organic fertilizer fermenting system

A fermentation system and organic fertilizer technology, which is applied in the direction of organic fertilizer, organic fertilizer preparation, inorganic fertilizer, etc., can solve the problems of occupying a large space, investing a large labor force, and high cost, so as to prevent air leakage and reduce Effects of air pollution and shortened fermentation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

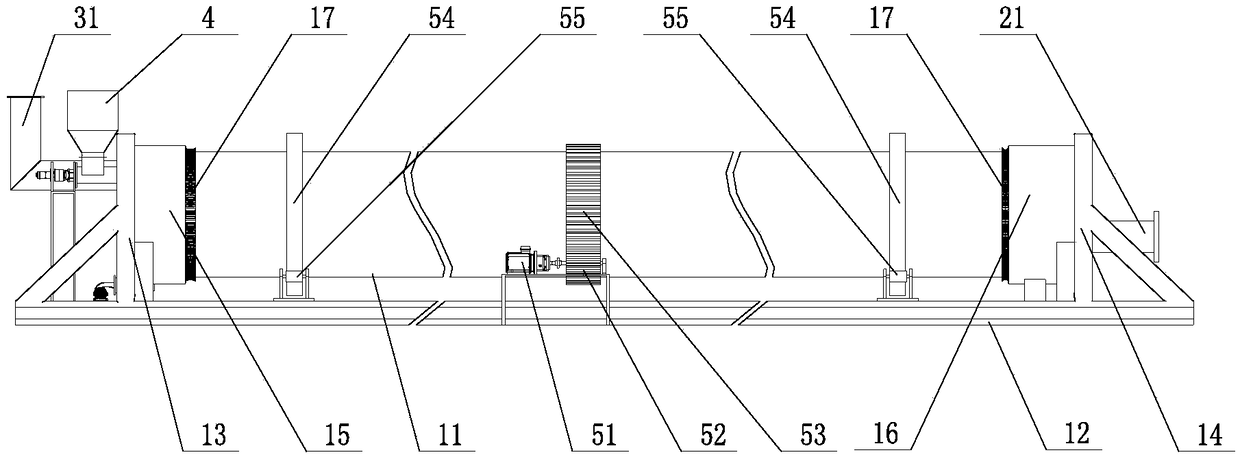

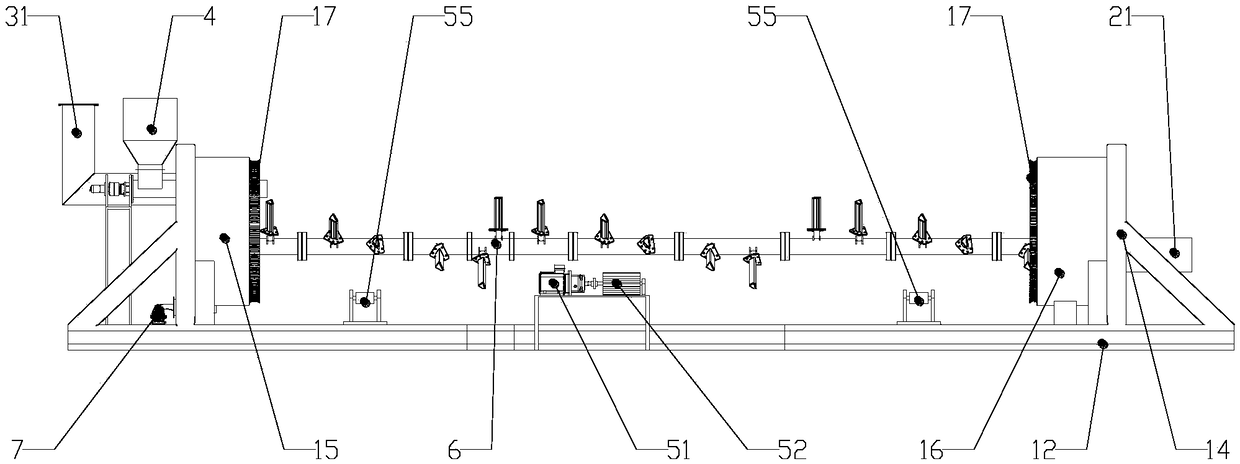

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

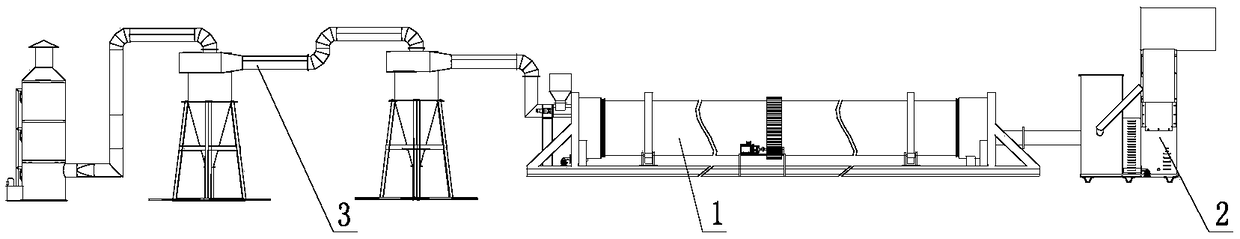

[0025] Such as figure 1 As shown, a horizontal organic fertilizer fermentation system of the present invention includes a fermentation device 1, a combustion device 2 and a waste gas treatment device 3, and the combustion device 2 and the waste gas treatment device 3 are respectively arranged at two ends of the fermentation device 1, wherein the combustion Device 2 is arranged at the rear end of fermentation device 1 ( figure 1 The middle is the right end), communicates with the interior of the fermentation drum 11 of the fermentation device 1 through the hot air ventilation pipe 21, and transports the hot air and ashes after the straw combustion into the fermentation drum 11, and the waste gas treatment device 3 is arranged at the front end of the fermentation device 1 ( figure 1 The middle is the left end), the waste gas treatment device 3 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com