Laboratory soil pretreatment closed box capable of realizing gas circulation and purification functions

A gas circulation and laboratory technology, applied in grain processing, dry gas arrangement, cocoa, etc., can solve problems such as unsatisfactory grinding effect, affecting detection efficiency, flying fine powder, etc., achieve the effect of green environmental protection, prevent environmental pollution, improve The effect of fineness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

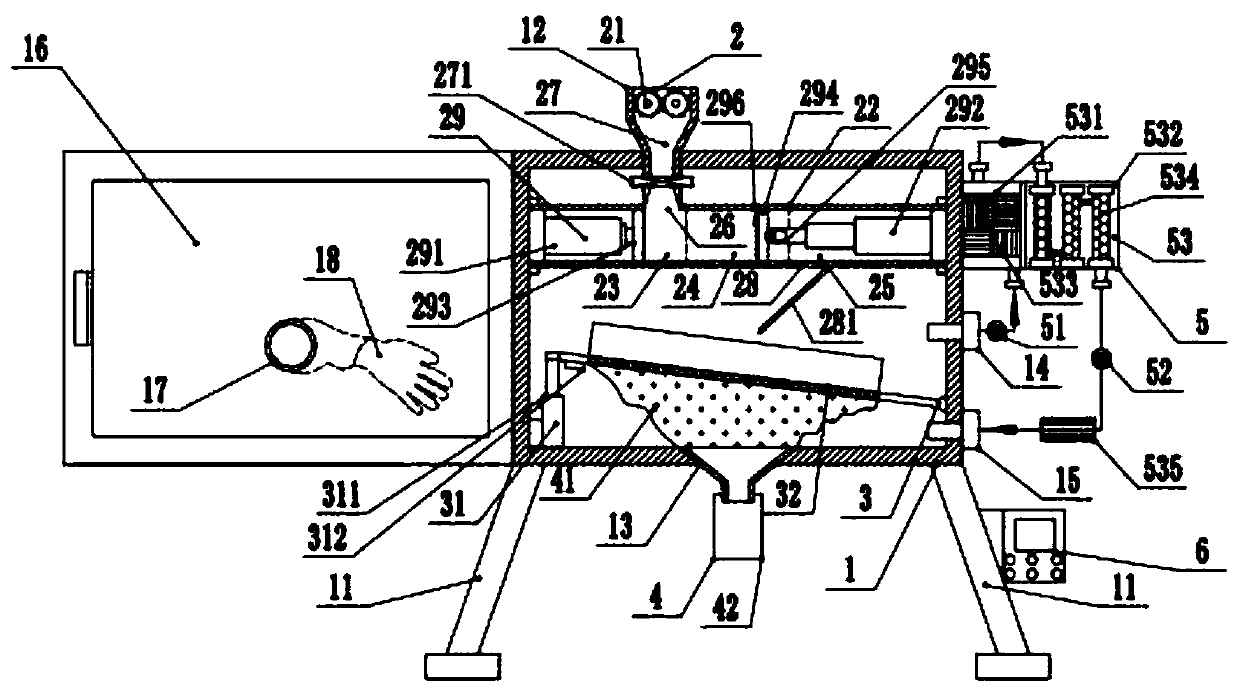

[0035] Such as figure 1 As shown, a laboratory soil pretreatment closed box that can realize gas circulation and purification functions includes a closed box 1, a crushing and grinding unit 2, a screening unit 3, a soil collection unit 4, a gas circulation unit 5 and a a controller 6 for controlling each unit,

[0036] Such as figure 1 As shown, the bottom of the closed box 1 is provided with a support frame 11, the top of the closed box 1 is provided with a feed port 12, the bottom is provided with a discharge port 13, and one side of the closed box 1 is provided with an air inlet 14 and an air inlet. Gas port 15, such as figure 1As shown, the front side of the closed casing 1 is provided with a push-pull glass airtight door 16, and the glass airtight door 16 is provided with a hole 17, and the hole 17 is connected with rubber gloves 18. After the sieving is completed, the cloth bag 41 is shaken by extending the hand into the rubber glove 18, and the soil powder attached t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com