Handcart type potato seeder

A hand-push and seeder technology, which is applied in the direction of sowing seeders, seeder parts, etc., and can solve problems such as troublesome operation and laboriousness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

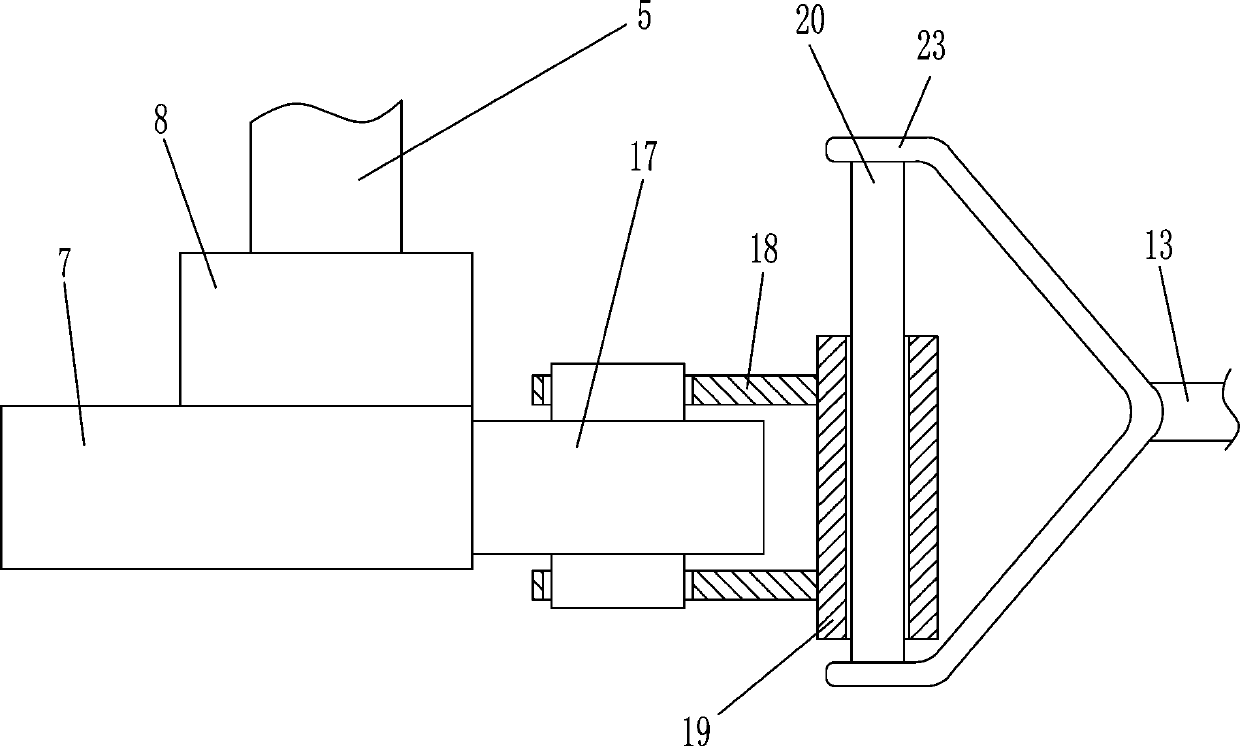

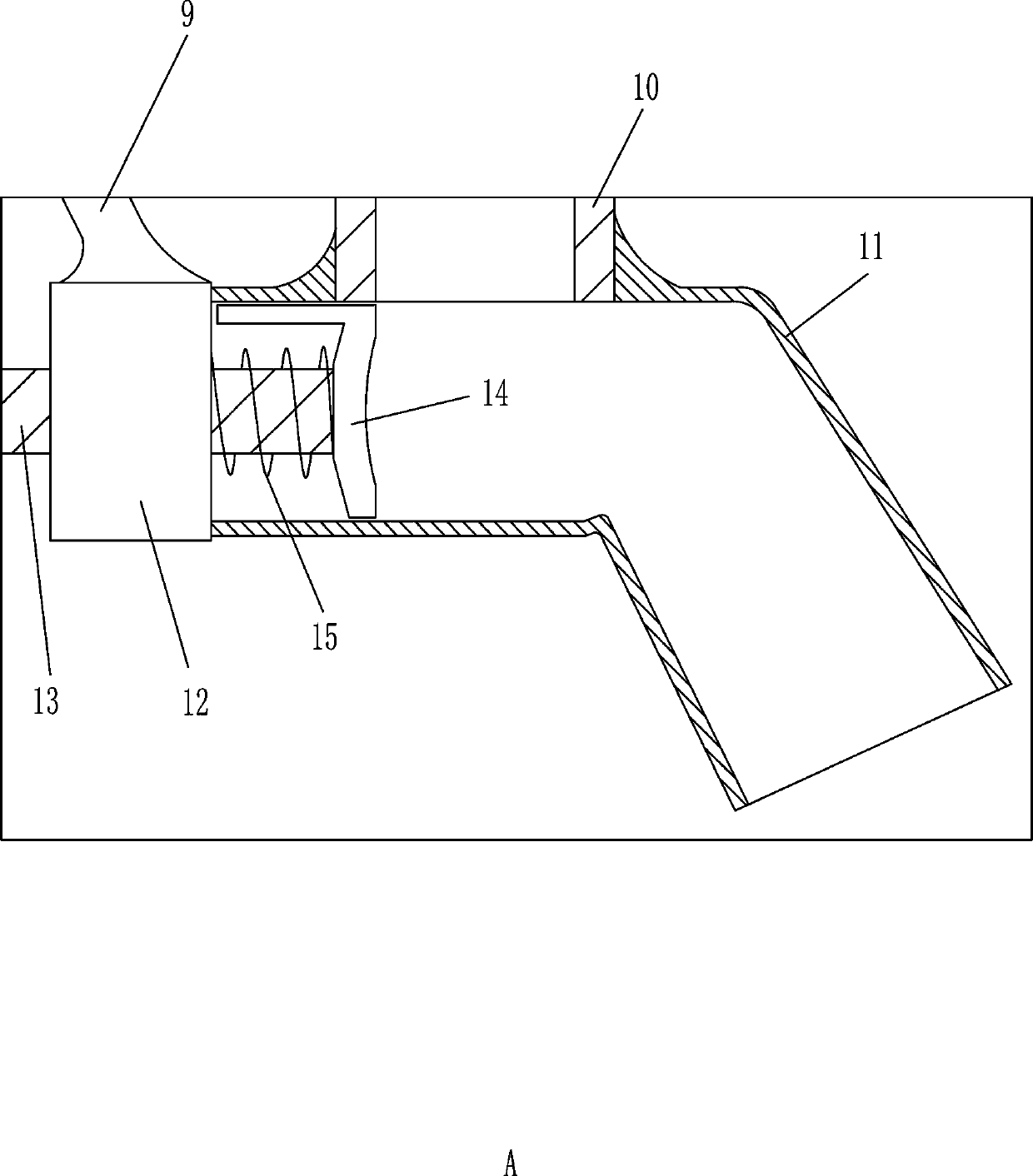

[0020] A hand-push potato planter such as Figure 1-4 As shown, it includes a mounting frame 1, a rib 2, a funnel 3, a push handle 4, a rotating shaft 5, a rough wheel 6, a first cam 7, a second cam 8, a first pole 9, a feeding tube 10, a curved Horn tube 11, pusher, second pole 16, contact wheel 17, fixed plate 18, sliding sleeve 19, slide rod 20, nut 21, fastening screw 22, connecting plate 23 and baffle plate 231, the middle connection of the bottom of funnel 3 There is a feeding pipe 10, which communicates with the funnel 3. The lower part of the feeding pipe 10 is slidingly provided with a baffle 231 that can block the potatoes. The bottom of the feeding pipe 10 is connected with a curved horn that can discharge the potatoes. Pipe 11, curved trumpet pipe 11 communicates with the feeding pipe 10, mounting frame 1 is installed on the left and right sides of the outer bottom of funnel 3, funnel 3 is connected to mounting frame 1 by welding, and the middle of the outer end of...

Embodiment 2

[0022] A hand-push potato planter such as Figure 1-4As shown, it includes a mounting frame 1, a rib 2, a funnel 3, a push handle 4, a rotating shaft 5, a rough wheel 6, a first cam 7, a second cam 8, a first pole 9, a feeding tube 10, a curved Horn tube 11, pusher, second pole 16, contact wheel 17, fixed plate 18, sliding sleeve 19, slide rod 20, nut 21, fastening screw 22, connecting plate 23 and baffle plate 231, the middle connection of the bottom of funnel 3 There is a feeding pipe 10, which communicates with the funnel 3. The lower part of the feeding pipe 10 is slidingly provided with a baffle 231 that can block the potatoes. The bottom of the feeding pipe 10 is connected with a curved horn that can discharge the potatoes. Pipe 11, curved trumpet pipe 11 communicates with the feeding pipe 10, mounting frame 1 is installed on the left and right sides of the outer bottom of funnel 3, and rotating shaft 5 is installed in the middle of the outer end of mounting frame 1, and...

Embodiment 3

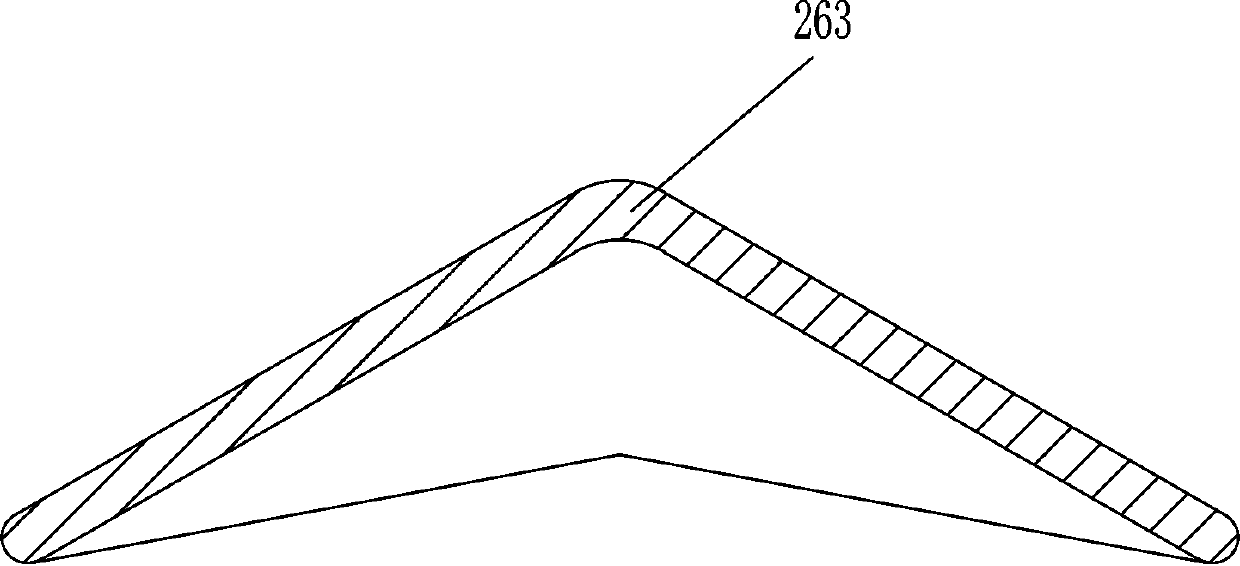

[0025] A hand-push potato planter such as Figure 1-5 As shown, it includes a mounting frame 1, a rib 2, a funnel 3, a push handle 4, a rotating shaft 5, a rough wheel 6, a first cam 7, a second cam 8, a first pole 9, a feeding tube 10, a curved Horn tube 11, pusher, second pole 16, contact wheel 17, fixed plate 18, sliding sleeve 19, slide rod 20, nut 21, fastening screw 22, connecting plate 23 and baffle plate 231, the middle connection of the bottom of funnel 3 There is a feeding pipe 10, which communicates with the funnel 3. The lower part of the feeding pipe 10 is slidingly provided with a baffle 231 that can block the potatoes. The bottom of the feeding pipe 10 is connected with a curved horn that can discharge the potatoes. Pipe 11, curved trumpet pipe 11 communicates with the feeding pipe 10, mounting frame 1 is installed on the left and right sides of the outer bottom of funnel 3, and rotating shaft 5 is installed in the middle of the outer end of mounting frame 1, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com