Pressure type solar panel cracking detection mechanism

A solar panel and detection mechanism technology, applied in the direction of circuit, electrical components, semiconductor/solid-state device testing/measurement, etc., can solve the problem of solar panel fragmentation detection not in place, achieve automatic detection, avoid influence, improve reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

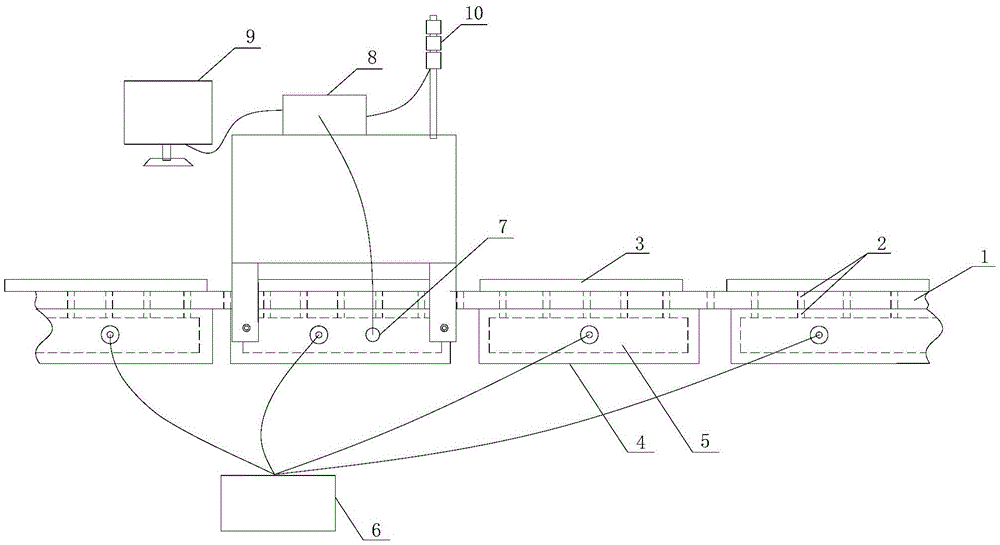

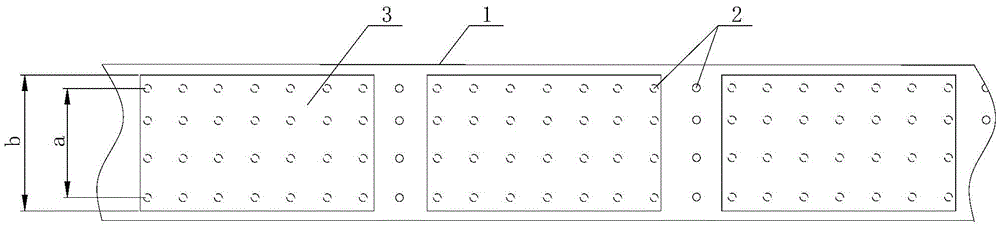

[0014] The present invention will now be described in detail with reference to the drawings. This figure is a simplified schematic diagram, which only illustrates the basic structure of the present invention in a schematic way, so it only shows the structure related to the present invention.

[0015] Such as Figure 1-2 As shown, a pressure-type solar panel chipping detection mechanism of the present invention includes a conveyor belt 1, a vacuum suction assembly and a pressure detection assembly. The conveyor belt 1 is provided with multiple rows of through holes 2 along the conveying direction of the conveyor belt 1. This embodiment The through holes 2 are in four rows. The distance a between the two outermost rows of through holes 2 is smaller than the side length b of the solar panel 3 in the width direction of the conveyor belt. The solar panel 3 is placed on the upper surface of the conveyor belt 1 and follows the conveyor belt. 1 move together, the vacuum suction assembly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com