Full-automatic pulling tape opening cut-off machine

A cutting machine, fully automatic technology, applied in the direction of sliding fastener components, applications, fasteners, etc., can solve the problems of high cost, low efficiency, time-consuming and labor-consuming, etc., to prolong the life of the upper and lower knives, cut off reliably, and ensure cutting open effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

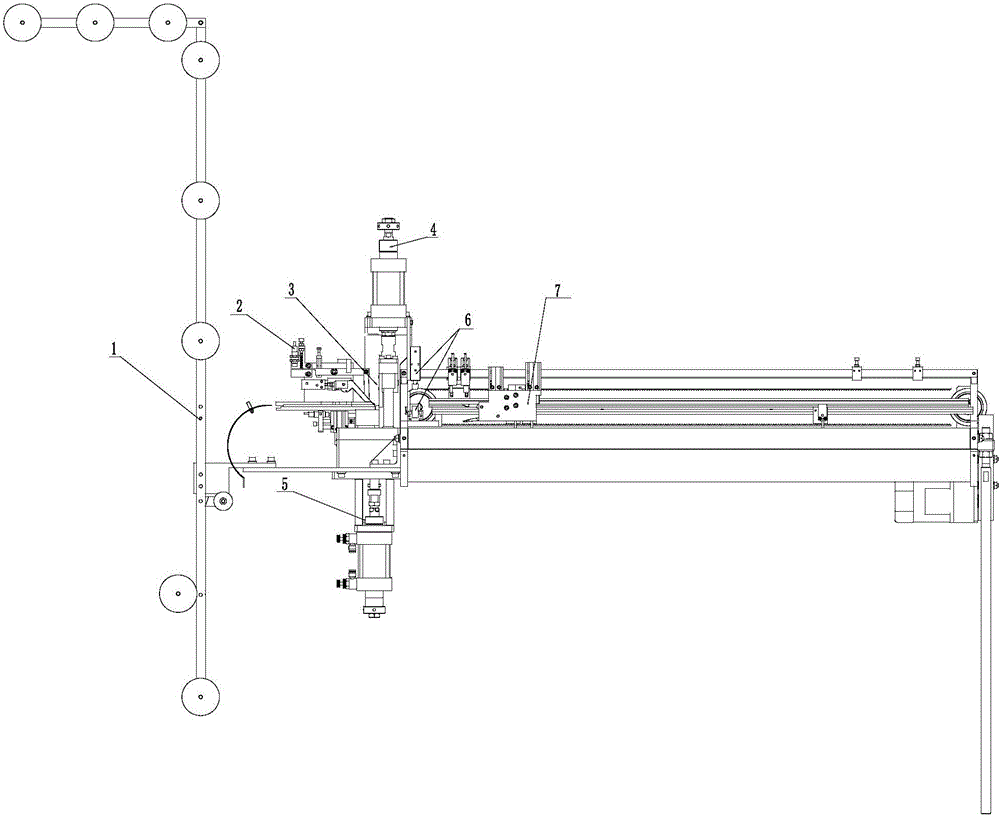

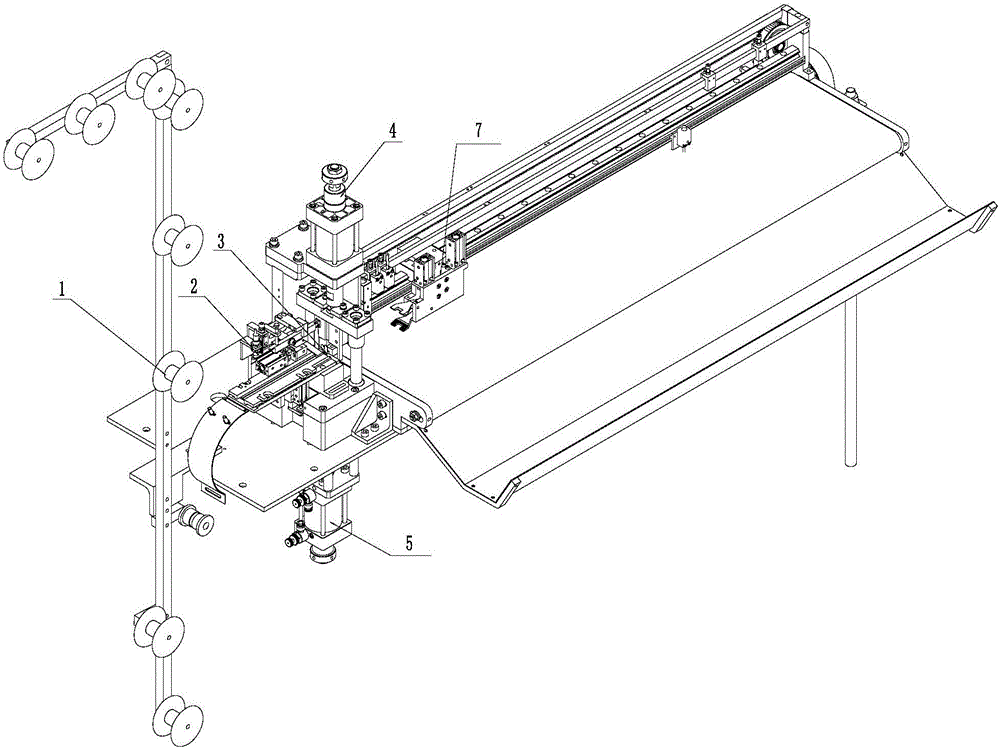

[0025] The present invention provides a fully automatic dragging opening cutting machine, which simultaneously completes the two tasks of cutting the zipper tape and moving the slider to the top of the zipper, such as figure 1 with figure 2 As shown, the present invention includes a belt feeding part 1, a formwork part 4, a lower knife movable part 5, a towing hand clip part 7, and also includes a chain pressing part 2, a crochet part 3 and a belt slider device 6;

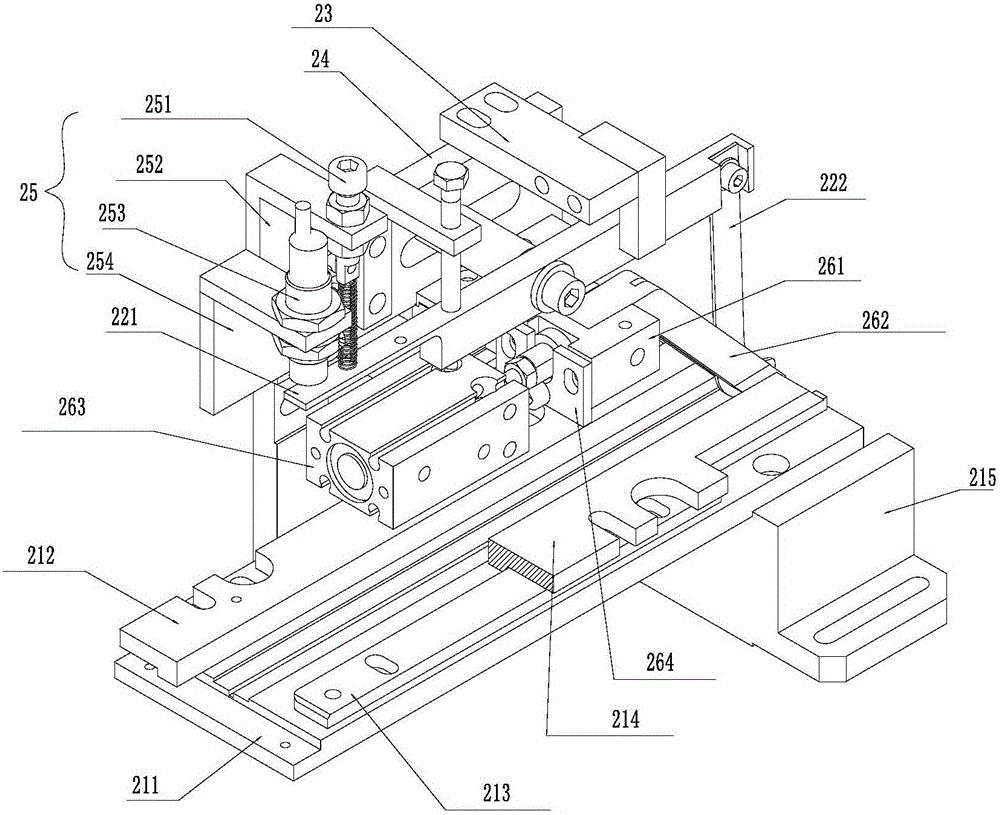

[0026] Such as image 3 As shown, the belt passing part of the pressure chain includes a belt pressure plate 211, a signal rod 221, a signal rod head 222, a fixing seat 23 and a mounting plate 24. Also be provided with the front adjusting plate 213 of crossing the chain, also be provided with left upper supporting plate 212 and the upper right supporting plate 214 on the adjusting p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com