Sesame threshing machine

A threshing machine and sesame technology, applied in threshing equipment, agricultural machinery and implements, applications, etc., can solve the problems of sesame waste, random projection of sesame, affecting follow-up work, etc., to achieve high work efficiency and avoid arm soreness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

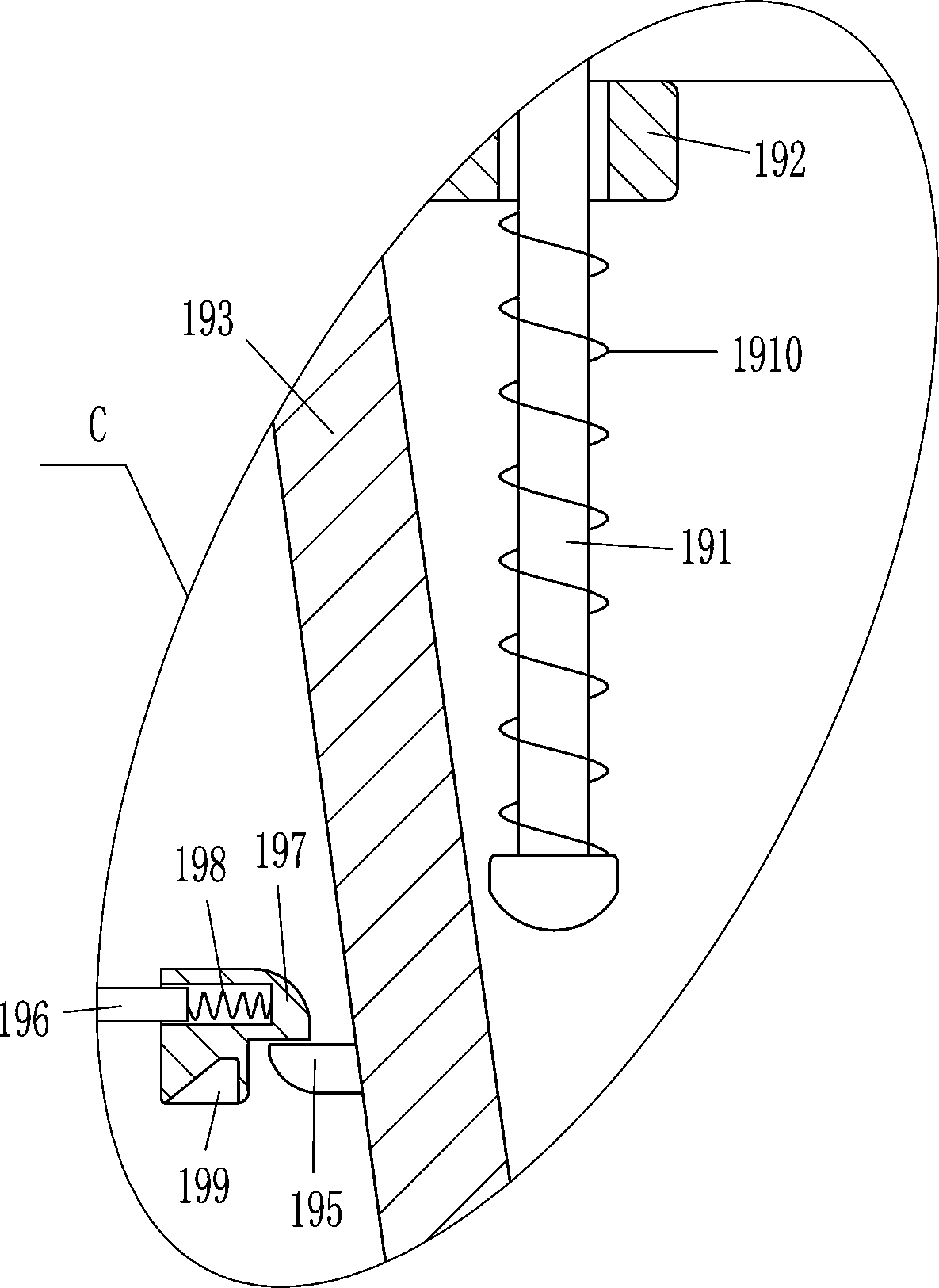

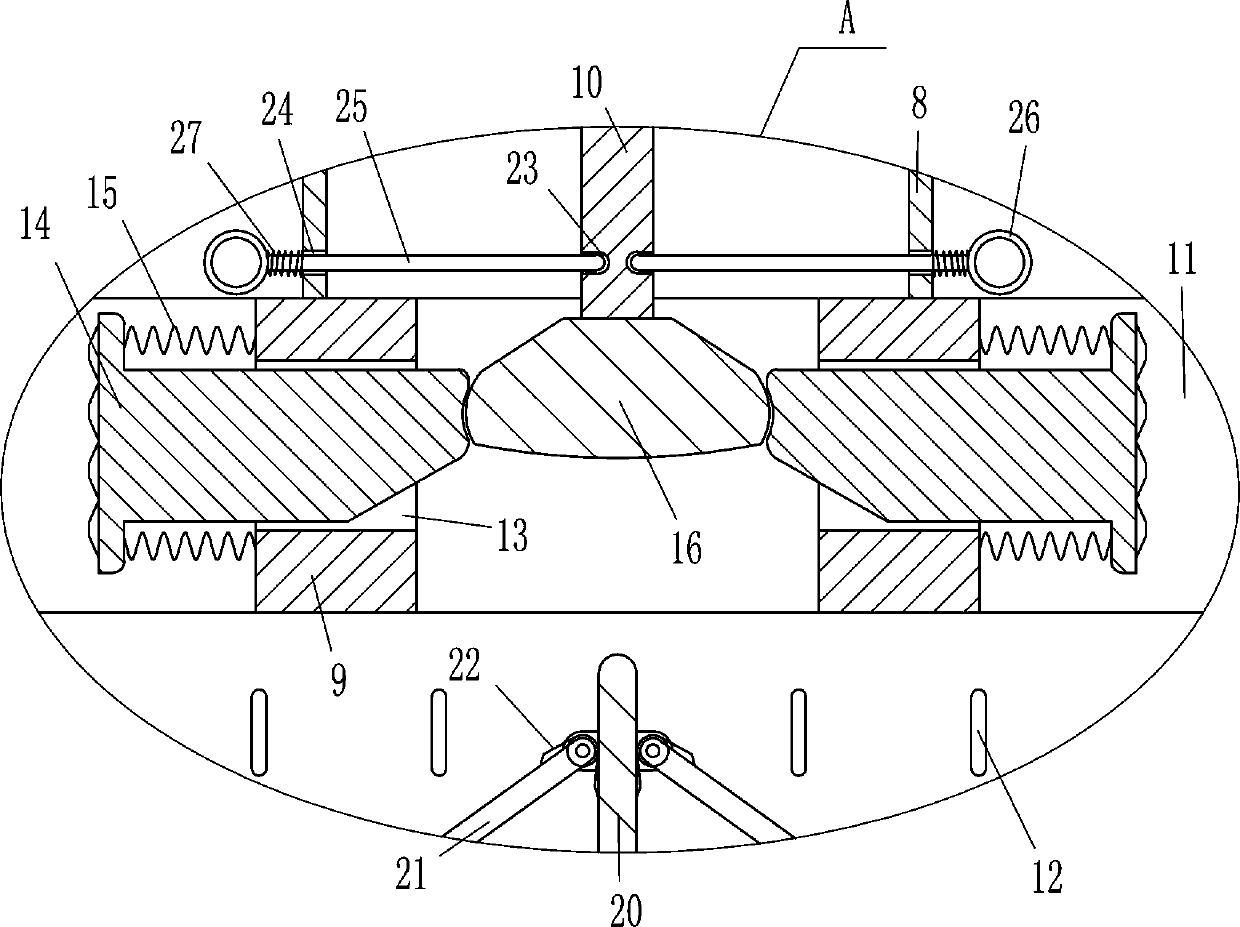

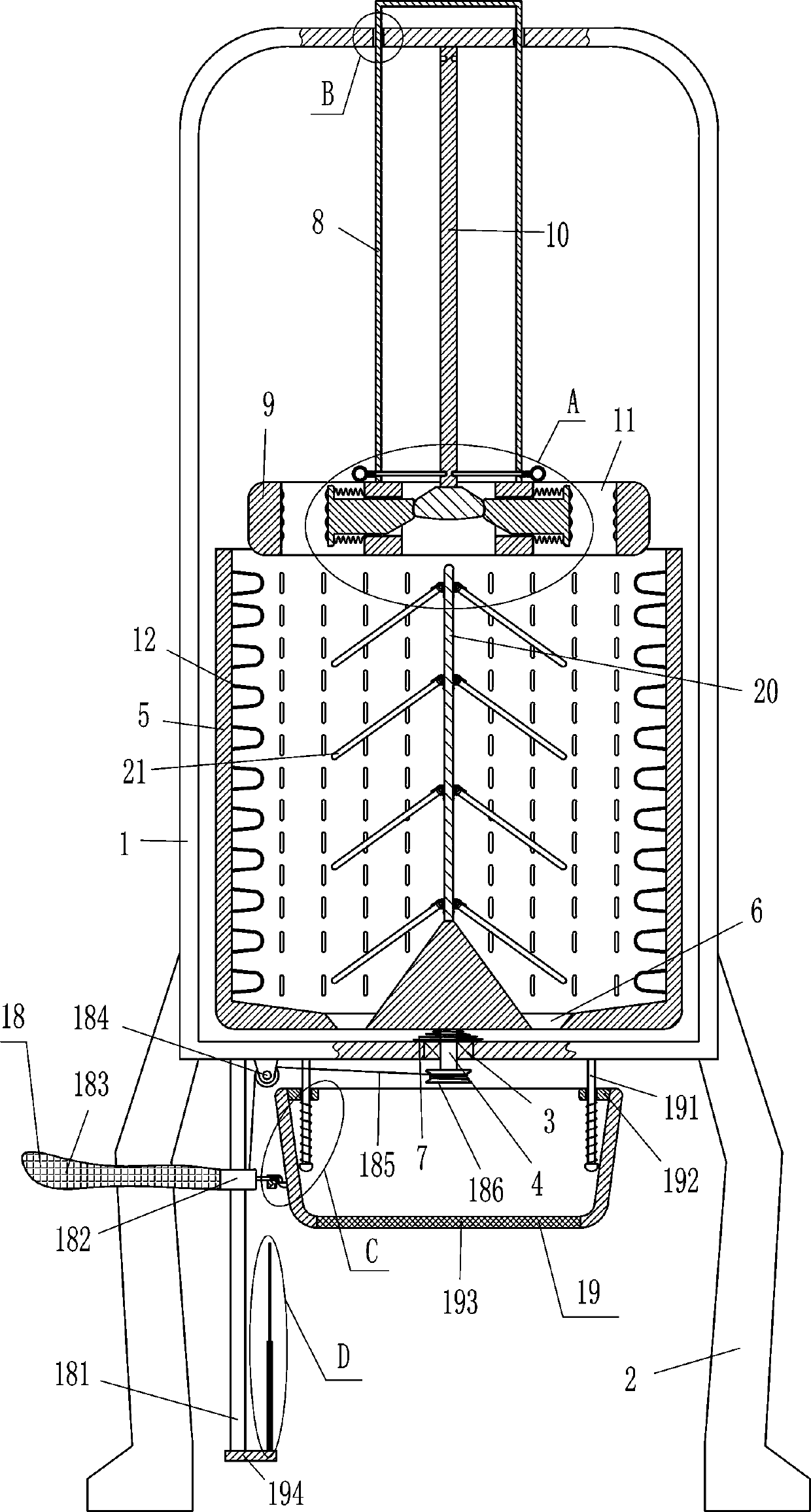

Embodiment 1

[0023] A sesame thresher such as Figure 1-5As shown, it includes a frame 1, a leg 2, a bearing seat 3, a rotating shaft 4, a cylinder 5, a scroll spring 7, an n-shaped rod 8, an annular block 9, a vertical rod 10, a u-shaped rod 12, a wedge-shaped block 14, The first spring 15, the fixed block 16 and the driving device 18, the lower parts of the outer left and right sides of the frame 1 are fixedly connected with the legs 2, the embedded one in the middle of the bottom of the frame 1 is fixedly connected with the bearing seat 3, and the rotating shaft 4 and the inner part of the bearing seat 3 Bearing connection, a driving device 18 is provided between the bottom end of the rotating shaft 4 and the left side of the outer bottom of the frame 1, the top of the rotating shaft 4 is fixedly connected to the cylinder 5, the cylinder 5 is located in the frame 1, the outer bottom of the cylinder 5 is connected to the inner bottom of the frame 1 A scroll spring 7 is connected between ...

Embodiment 2

[0025] A sesame thresher such as Figure 1-5 As shown, it includes a frame 1, a leg 2, a bearing seat 3, a rotating shaft 4, a cylinder 5, a scroll spring 7, an n-shaped rod 8, an annular block 9, a vertical rod 10, a u-shaped rod 12, a wedge-shaped block 14, The first spring 15, the fixed block 16 and the driving device 18, the lower parts of the outer left and right sides of the frame 1 are fixedly connected with the legs 2, the embedded one in the middle of the bottom of the frame 1 is fixedly connected with the bearing seat 3, and the rotating shaft 4 and the inner part of the bearing seat 3 Bearing connection, a driving device 18 is provided between the bottom end of the rotating shaft 4 and the left side of the outer bottom of the frame 1, the top of the rotating shaft 4 is fixedly connected to the cylinder 5, the cylinder 5 is located in the frame 1, the outer bottom of the cylinder 5 is connected to the inner bottom of the frame 1 A scroll spring 7 is connected between...

Embodiment 3

[0028] A sesame thresher such as Figure 1-5 As shown, it includes a frame 1, a leg 2, a bearing seat 3, a rotating shaft 4, a cylinder 5, a scroll spring 7, an n-shaped rod 8, an annular block 9, a vertical rod 10, a u-shaped rod 12, a wedge-shaped block 14, The first spring 15, the fixed block 16 and the driving device 18, the lower parts of the outer left and right sides of the frame 1 are fixedly connected with the legs 2, the embedded one in the middle of the bottom of the frame 1 is fixedly connected with the bearing seat 3, and the rotating shaft 4 and the inner part of the bearing seat 3 Bearing connection, a driving device 18 is provided between the bottom end of the rotating shaft 4 and the left side of the outer bottom of the frame 1, the top of the rotating shaft 4 is fixedly connected to the cylinder 5, the cylinder 5 is located in the frame 1, the outer bottom of the cylinder 5 is connected to the inner bottom of the frame 1 A scroll spring 7 is connected between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com