A high-efficiency steam turbine seal structure between high and medium pressure

A steam seal body, high and medium pressure technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve the problems of high and medium pressure steam inlet efficiency limitation, damage, steam turbulence and reduced steam flow, and achieve high steam inlet efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

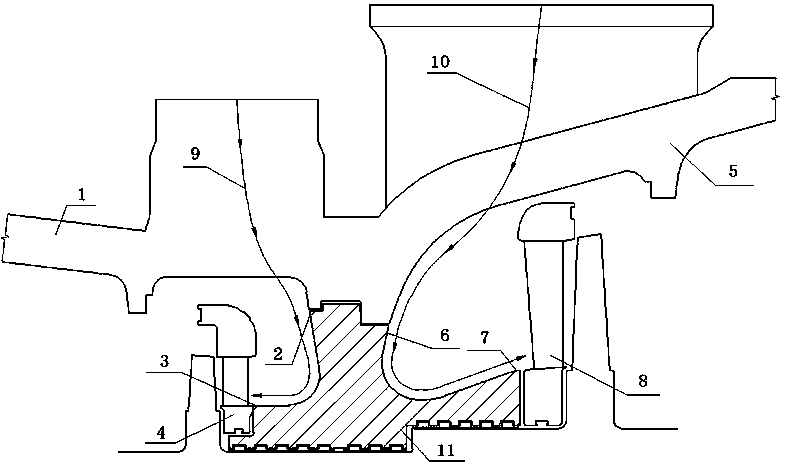

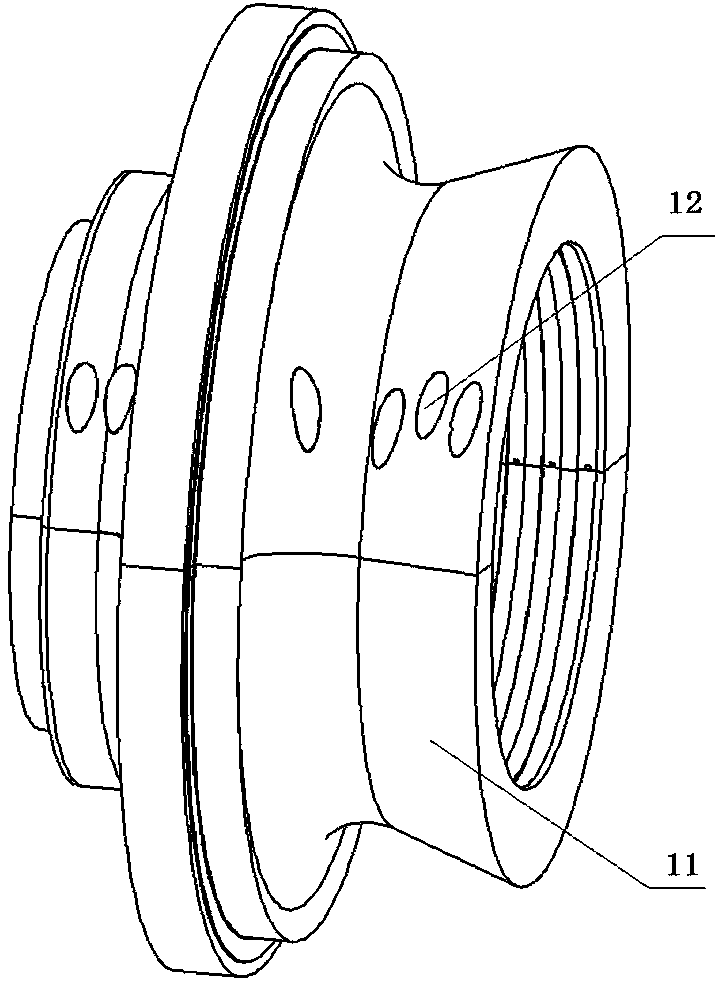

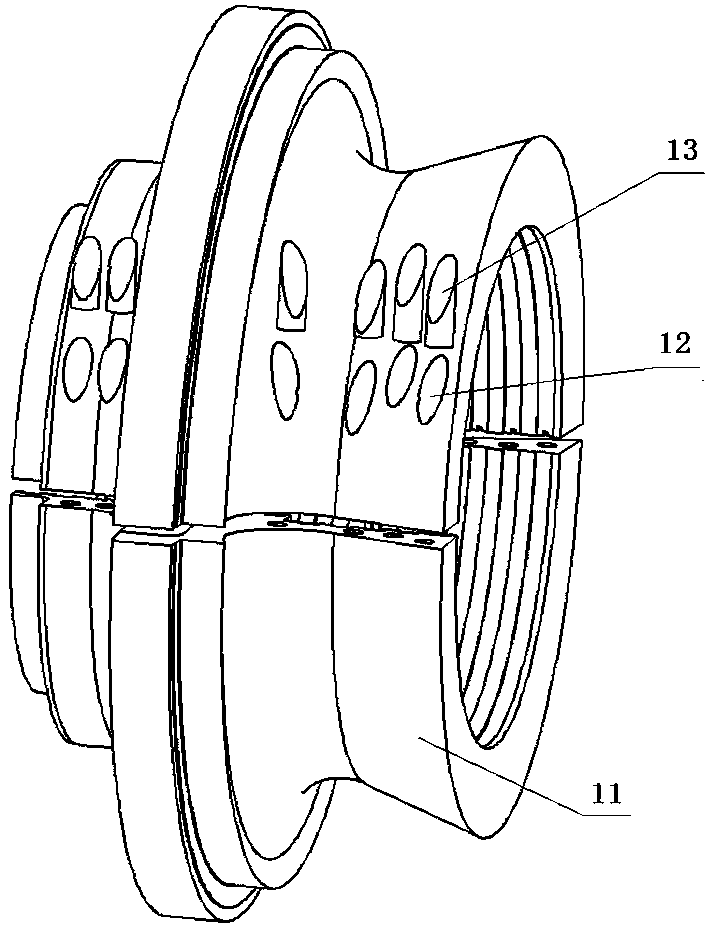

[0012] like Figure 1 to Figure 2 As shown, a high-efficiency steam turbine high and medium pressure intermediate seal body structure, the high and medium pressure intermediate pressure seal body 11 has a seal body high pressure steam inlet end profile 2 on the high pressure side, and a seal body high pressure steam outlet end profile 3; The profile line 6 of the medium-pressure steam inlet end of the gland body on the medium-pressure side, and the profile line 7 of the medium-pressure steam outlet end of the gland body; it is characterized in that: the profile line 2 of the high-pressure steam inlet end of the gland body and the type 1 cylinder of the high-pressure side Lines are matched, the profile line 3 of the high-pressure steam outlet end of the gland body matches the inlet of the high-pressure first-stage partition 4; the profile line 6 of the medium-pressure steam inlet end of the gland body matches the profile line 5 of the medium-pressure side cylinder Matching, the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap