350mw supercritical three-cylinder two-row steam-humidity condensing steam turbine

A steam turbine and supercritical technology, applied in steam engine devices, combined engines, mechanical equipment, etc., can solve problems such as low cylinder efficiency and large cylinder flow loss, and achieve the effects of improving efficiency, reducing pressure, and excellent structural technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

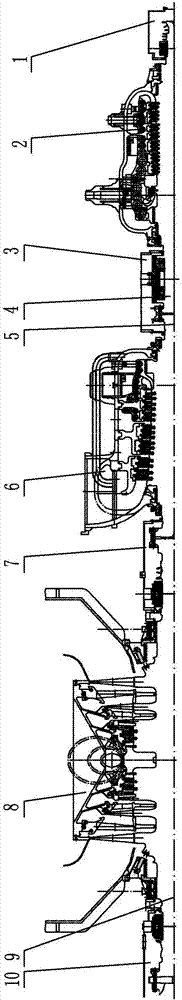

[0018] Specific implementation mode one: as figure 1 As shown, the 350MW supercritical three-cylinder two-row steam-humidity-condensing steam turbine in this embodiment includes a front bearing housing 1, a high-pressure cylinder 2, a first middle bearing housing 3, a steam turbine shafting high-pressure rotor 4, and a steam turbine shafting medium-pressure rotor 5. Medium pressure cylinder 6, second medium bearing box 7, low pressure cylinder 8, steam turbine shaft low pressure rotor 9 and rear bearing box 10, front bearing box 1, first middle bearing box 3, second middle bearing box 7 and rear The bearing boxes 10 are all installed on the frame with a floor structure, the high-pressure cylinder 2 is supported on the front bearing box 1 and the first middle bearing box 3 through the upper cat claws, and the medium-pressure cylinder 6 is supported on the first middle bearing box through the upper cat claws 3 and the second middle bearing box 7; the low-pressure cylinder 8 is i...

specific Embodiment approach 2

[0025] Specific implementation mode two: as figure 1 As shown, in this embodiment, the high-pressure cylinder 2 and the medium-pressure cylinder 6 are all single-flow cylinders, and the low-pressure cylinder 8 is a double-flow cylinder. Such a design can effectively balance the axial thrust of the rotor and make the overall design of the shaft system more reasonable. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0026] Specific implementation mode three: as figure 1 As shown, the high-pressure main steam regulating combined valve in this embodiment is symmetrically arranged on both sides of the high-pressure cylinder 2, and the high-pressure main steam regulating combined valve is respectively connected to the upper and lower sides of the high-pressure cylinder 2 with air guide pipes, and the high-pressure main steam regulating combined valve and the foundation are Rigid support. Designed in this way, the cylinder flow pattern set up in this way can not only improve the efficiency of each cylinder, but also effectively shorten the axial dimension of the unit, control the length of the final stage blade and reduce the axial thrust of the rotor. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com