50MW-grade axial flow sCO2 turbine

An axial flow and turbine technology, which is applied in the direction of machines/engines, non-variable engines, wind power generation, etc., can solve the problems of severe physical and chemical changes, unstable turbine operation, etc., and achieve low air intake loss and low circumferential pressure. Uniform, high cylinder efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

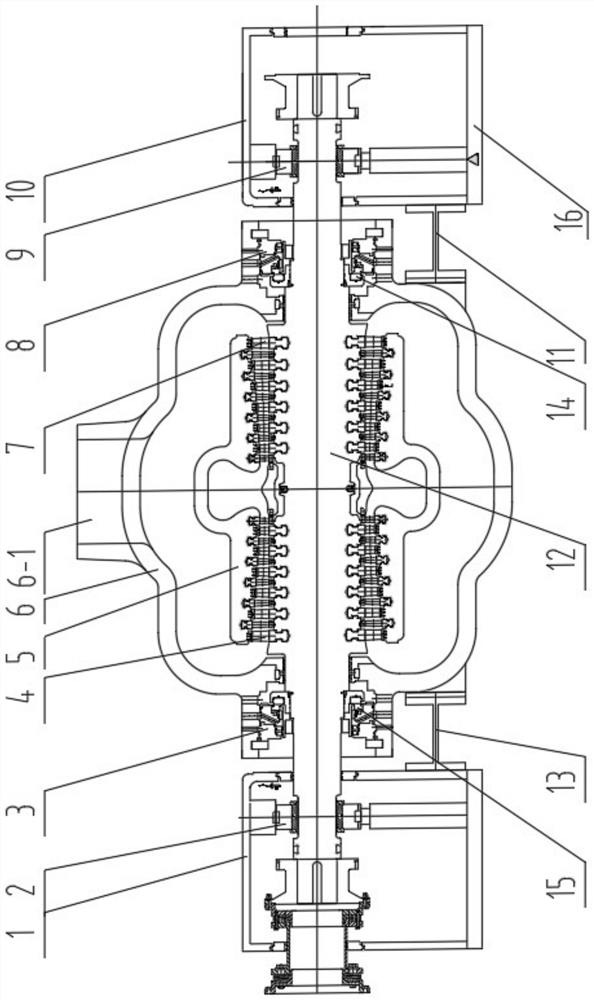

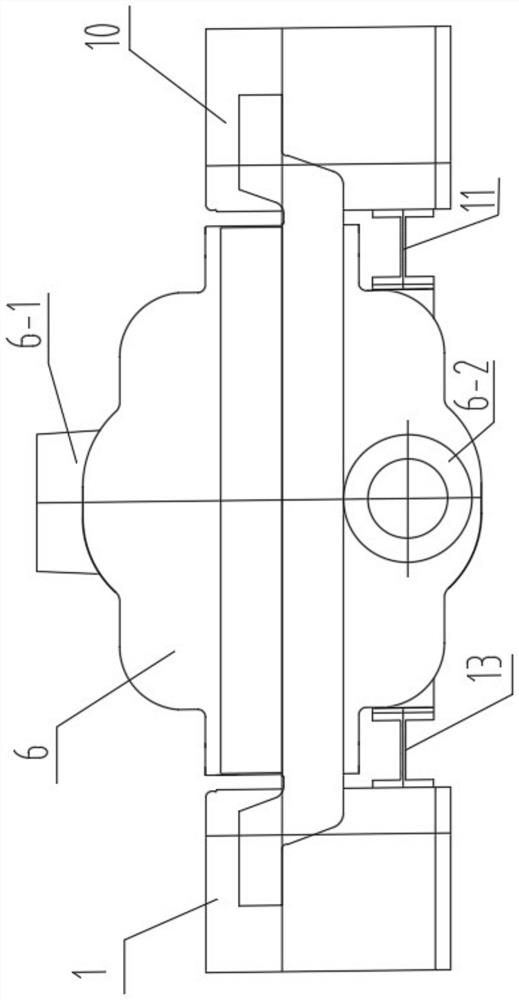

[0020] Specific embodiment 1: A 50MW grade axial flow sCO 2 The turbine includes a front bearing box 1, an inner cylinder 5, an outer cylinder 6, a rear bearing box 10 and a base frame 16;

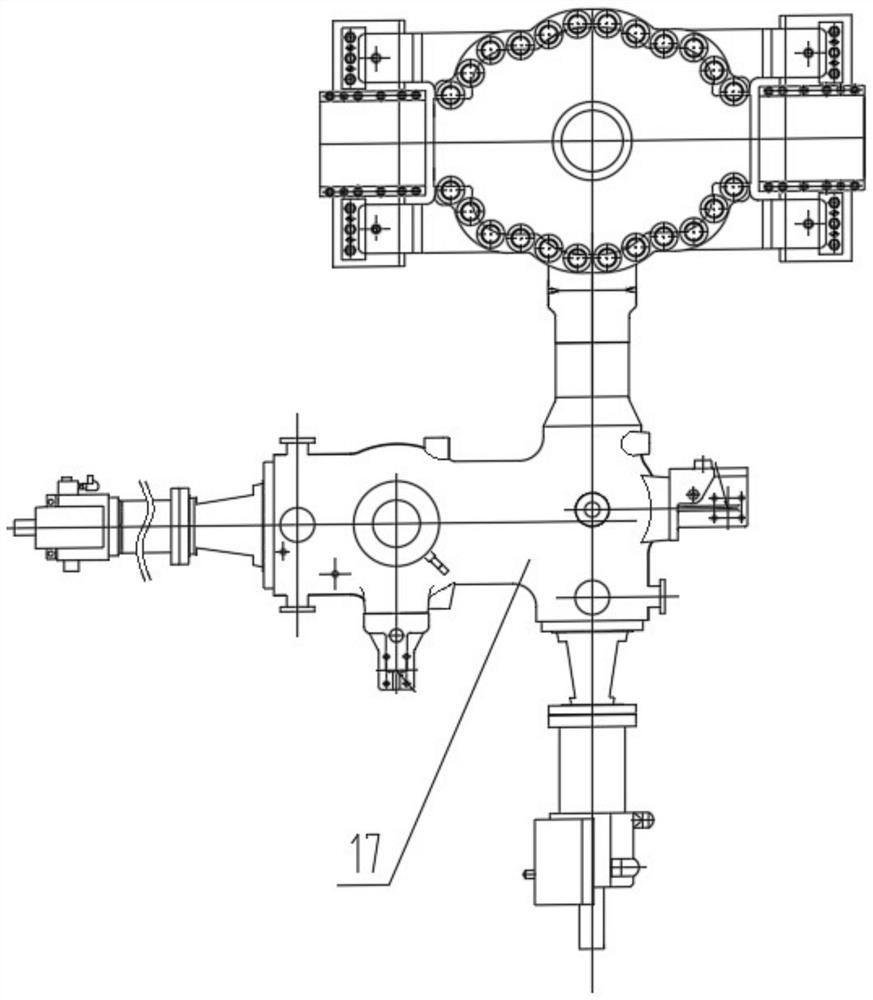

[0021] The front bearing box 1 and the rear bearing box 10 are installed on both sides of the outer cylinder 6, the front bearing box 1 and the rear bearing box 10 are both arranged on the base frame 16, and the lower part of the front end of the outer cylinder 6 is connected to the front end through the front centering beam structure 13. The bearing box 1 is connected, the lower rear end of the outer cylinder 6 is connected to the rear bearing box 10 through the rear centering beam structure 11, the exhaust port 6-1 of the outer cylinder 6 is arranged on the top of the outer cylinder 6, and the air inlet 6 of the outer cylinder 6 -2 is provided at the lower part of the side of the outer cylinder 6, and the intake port 6-2 is connected to an intake valve 17.

[0022] In this embodiment: c...

specific Embodiment approach 2

[0024] Specific embodiment 2: A 50MW grade axial flow sCO 2 Turbine, the intake valve 17 is the main gas regulating combined valve.

[0025] Other specific embodiments are the same as the first specific embodiment.

specific Embodiment approach 3

[0026] Specific embodiment three: a 50MW grade axial flow sCO 2 Turbine, the outer cylinder 6 is provided with a rotor 12, the inner cylinder 5 is arranged outside the rotor 12, the front half of the inner cylinder 5 and the rotor 12 are provided with a reverse blade 4 installed on the rotor 12, and the rear half of the inner cylinder There is a forward blade 7 installed on the rotor 12 between the segment and the rotor 12. The front end of the rotor 12 is connected with the front end bearing 2 in the front bearing housing 1, and the rear end of the rotor 12 is connected with the rear end bearing 9 in the rear bearing housing 10. .

[0027] In this embodiment, the through-flow part adopts a double-split structure, the reverse blade and the forward blade are geometrically symmetrical, and the axial thrusts balance each other, which solves the problem of CO 2 Changes in physical properties bring about changes in thrust;

[0028] Preferably, the inner cylinder is equipped with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com