100MW single-cylinder air-cooling photo-thermal steam turbine

A steam turbine, cold light technology, applied in mechanical equipment, engine components, combined engines, etc., to achieve the effects of high cycle efficiency, improved back pressure, and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

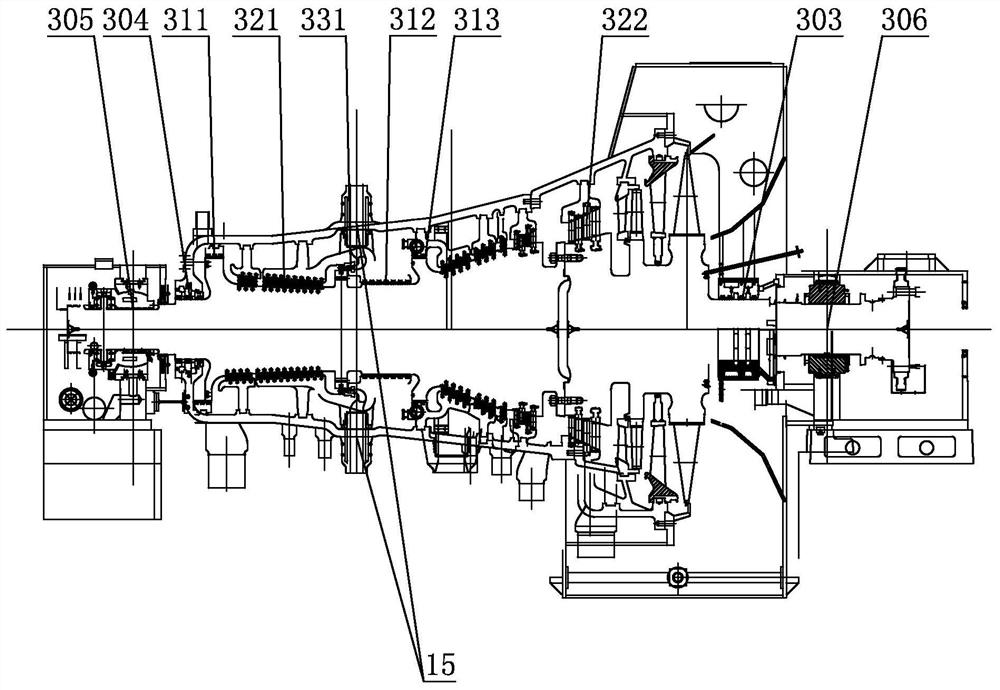

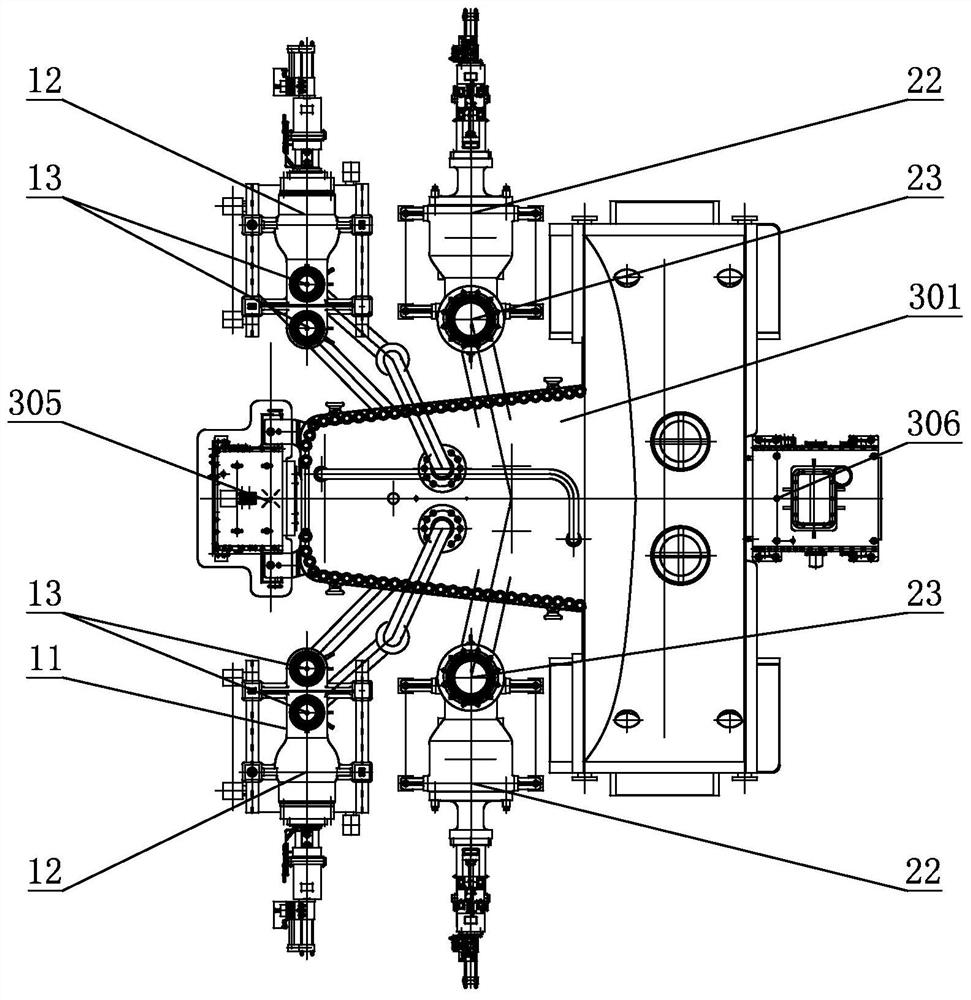

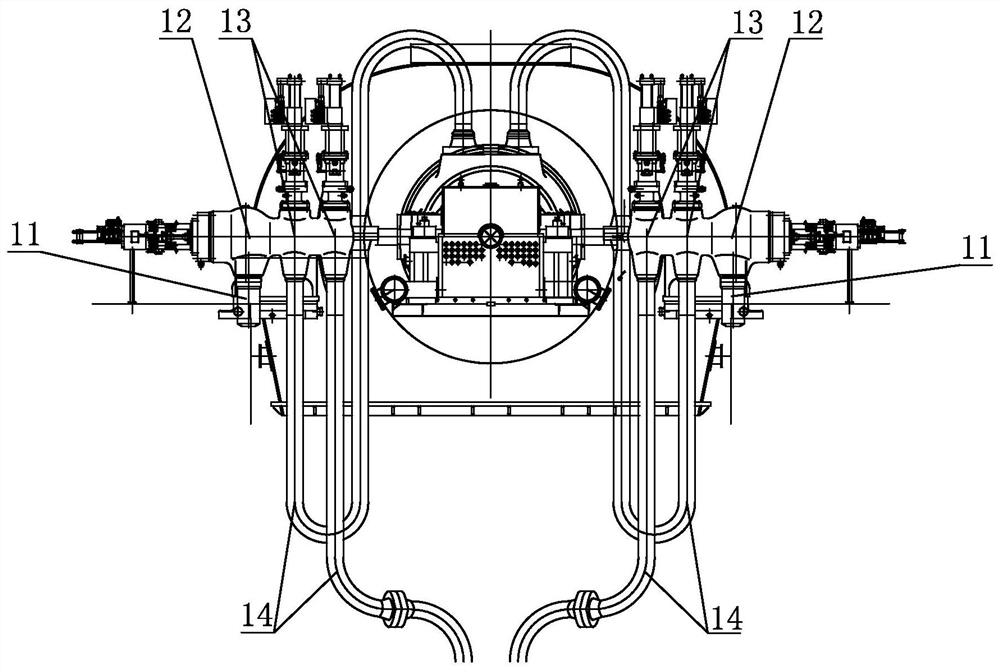

[0026] Specific implementation mode one: combine Figure 1 to Figure 6 Describe this embodiment, a 100MW single-cylinder air-cooled photothermal steam turbine in this embodiment, which includes a high-pressure steam guide assembly, a medium-pressure steam guide assembly, and a high, medium, and low pressure combined cylinder module. section rotor 302, rotor 307 of the low temperature section of the steam turbine, low exhaust end steam seal 303, high exhaust end steam seal 304, front bearing housing 305, rear bearing housing 306, rotor thrust bearing a and rotor thrust bearing b, steam turbine high temperature section rotor 302 and The rotor 307 of the low-temperature section of the steam turbine is arranged horizontally, one end of the rotor 302 of the high-temperature section of the steam turbine is rotationally connected with the front bearing box 305 through the rotor thrust bearing a, and the front bearing box 305 is arranged on the ground, and the other end of the rotor 30...

specific Embodiment approach 2

[0030] Specific implementation mode two: combination Figure 1 to Figure 6 To illustrate this embodiment, the rear of each high-pressure regulating valve 13 and high-pressure steam inlet pipe 15 in this embodiment is provided with several regulating nozzles. With such a setting, the steam intake method of nozzle adjustment is adopted, and it has the ability to quickly adjust the load. Each high-pressure regulating valve 13 corresponds to a certain number of regulating stage nozzles, and the flow rate of the main steam entering the high-pressure cylinder 403 is controlled by the number and degree of opening of the high-pressure regulating valve 13 . Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0031] Specific implementation mode three: combination Figure 1 to Figure 6 To illustrate this embodiment, the high, medium and low pressure combined cylinder module of this embodiment also includes a high-pressure exhaust steam balance drum 311, a high-pressure steam inlet balance drum 312, and a medium-pressure steam inlet balance drum 313, and the high-pressure exhaust steam balance drum 311 is arranged at the high-pressure exhaust port At 3012, the high-pressure exhaust steam balance drum 311 is installed on the inner wall of the cylinder body 301, and the high-pressure steam inlet balance drum 312 is installed at the high-pressure steam inlet 3011, and the high-pressure steam inlet balance drum 312 is installed on the inner wall of the cylinder body 301, The medium-pressure steam inlet balance drum 313 is arranged at the medium-pressure steam inlet 3013, the medium-pressure steam inlet balance drum 313 is installed on the inner wall of the cylinder body 301, the high-pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com