A kind of preparation method of high power pulse battery capacitor

A high-power pulse and battery capacitor technology, used in fixed capacitor parts, capacitors, fixed capacitor electrodes, etc., can solve the problem of rapid product cycle life decay, poor high current discharge performance, low specific capacity of lithium titanate, etc. problems, to achieve the effect of improving high-power pulse performance, improving safety and reliability, and long pulse duration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

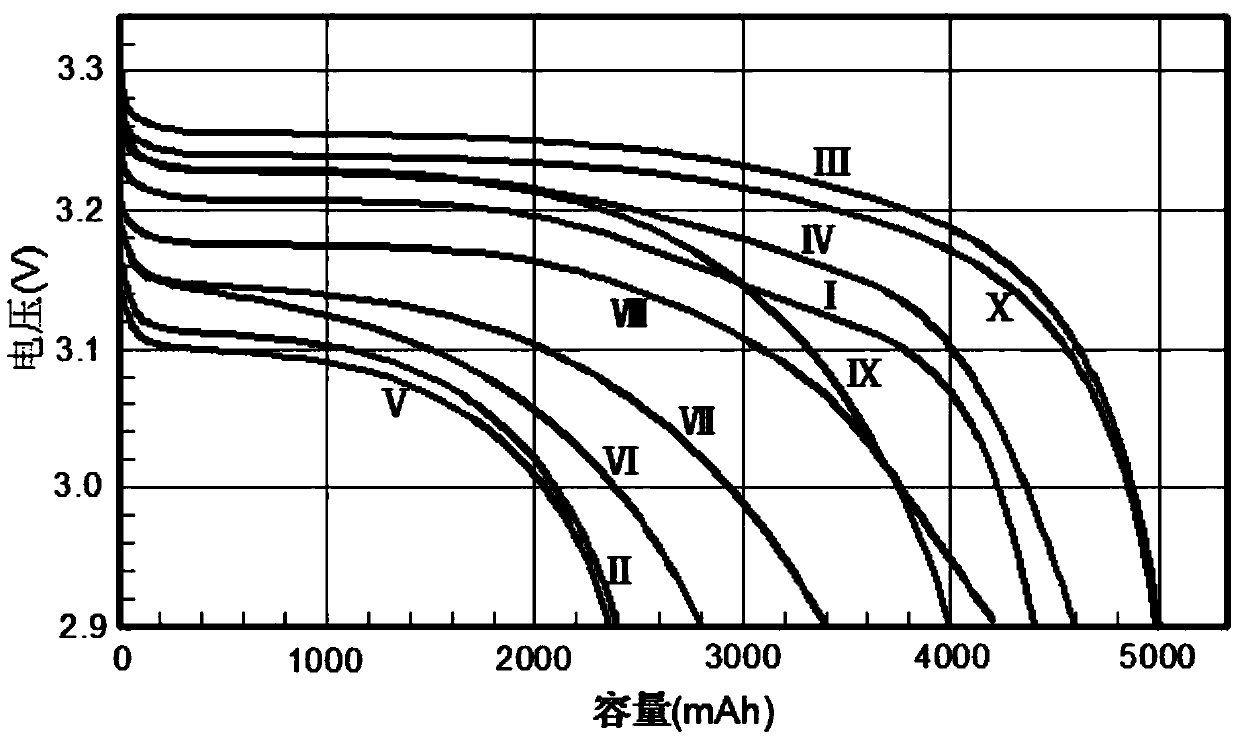

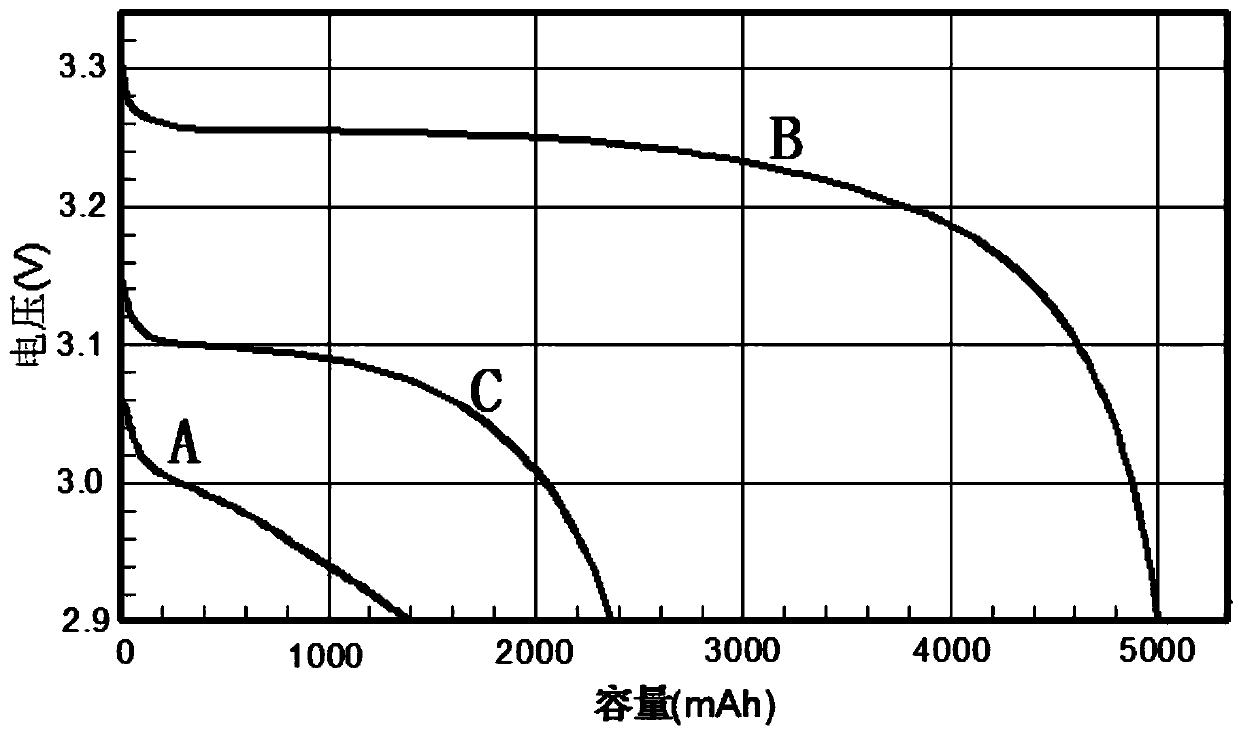

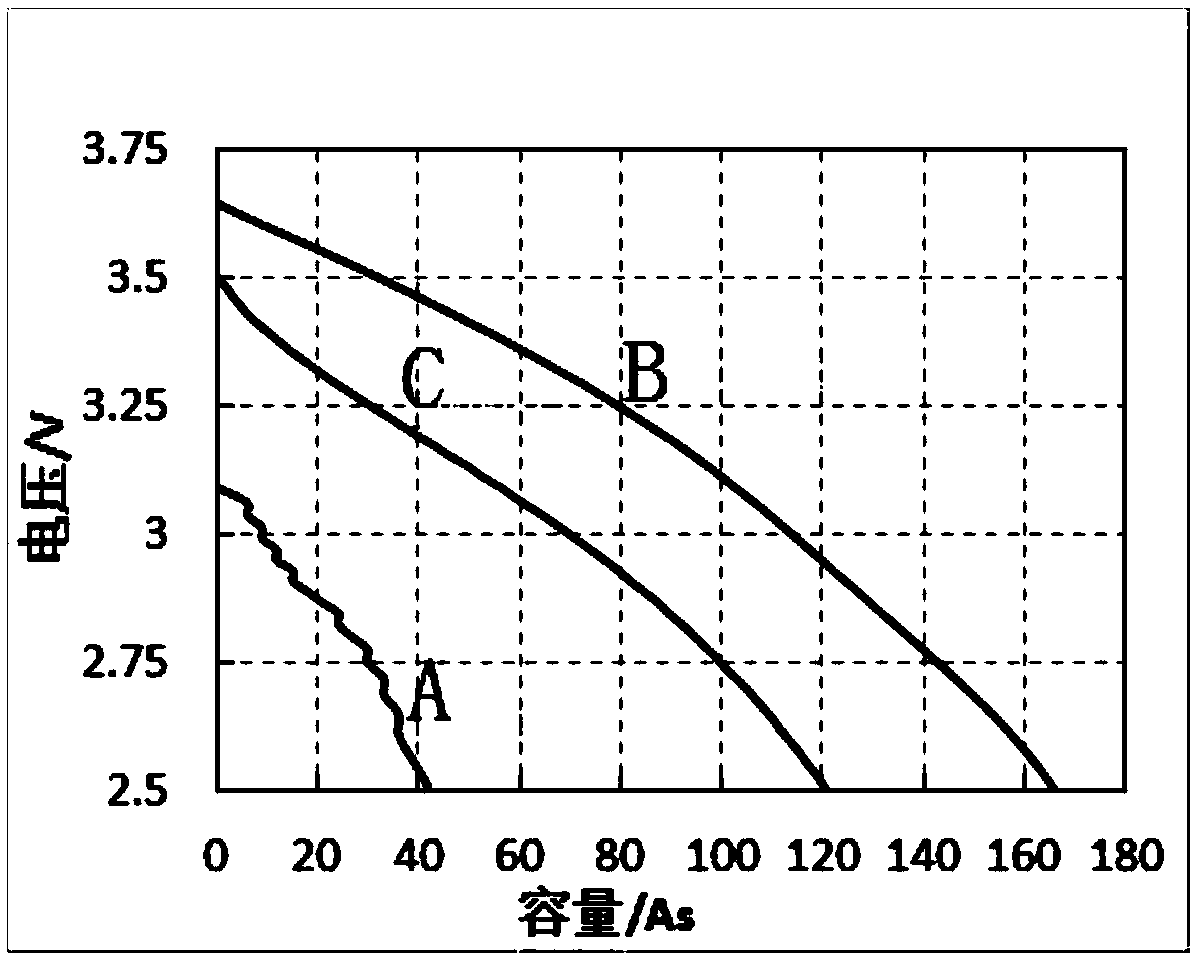

[0030] A preparation method for a high-power pulse battery capacitor, including a method for a high-power pulse battery capacitor, a high-power pulse battery capacitor comprising a positive pole, a negative pole, a separator, and an electrolyte lithium salt; the positive pole is composed of Li(NiFeCoMoMn) O2, activated carbon, PVDF, CMC are composed; the negative electrode is composed of graphite, activated carbon, SBR, CMC; the electrolyte lithium salt is composed of LiPF6, LiBF4; the capacitor is a cylindrical fully sealed structure; the positive electrode is composed of It is composed of 40-80 parts of Li(NiFeCoMoMn)O2, 10-40 parts of activated carbon, 1-20 parts of PVDF, and 1-20 parts of CMC; the negative electrode is composed of 50-90 parts by weight of graphite, 1-20 parts of 1 to 20 parts of activated carbon, 1 to 20 parts of SBR, and 1 to 20 parts of CMC; the lithium salt of the electrolyte is composed of 1 to 20 parts of LiPF6 and 1 to 20 parts of LiBF4 in parts by we...

Embodiment 1

[0043] A high-power pulse battery capacitor, the positive pole is composed of 40 parts by weight of Li(NiFeCoMoMn)O2, 40 parts of activated carbon, 5 parts of PVDF, and 20 parts of CMC; the negative pole is composed of 50 parts by weight Part of graphite, 1 part of activated carbon, 5 parts of SBR, 6 parts of CMC; the electrolyte lithium salt is composed of 6 parts of LiPF6 and 20 parts of LiBF4 in parts by weight.

[0044] The method for preparing the above-mentioned high-power pulse battery capacitor is characterized in that it includes the following steps:

[0045] Step 1: Prepare the positive electrode: Weigh Li(NiFeCoMoMn)O2, activated carbon, PVDF, and CMC in the above weight fractions, and stir evenly to obtain the positive electrode slurry; coat the positive electrode slurry on the aluminum foil to obtain the positive electrode, and the size of the positive electrode is 0.07 thick ~0.12mm×width 7.0~9.5mm×length 360~450mm;

[0046] Step 2: Preparation of negative elect...

Embodiment 2

[0051] A high-power pulse battery capacitor, the positive pole is composed of 80 parts by weight of Li(NiFeCoMoMn)O2, 10 parts of activated carbon, 13 parts of PVDF, and 1 part of CMC; the negative pole is composed of 90 parts by weight Parts of graphite, 5 parts of activated carbon, 7 parts of SBR, 1 part of CMC; the electrolyte lithium salt is composed of 7 parts of LiPF6 and 15 parts of LiBF4 in parts by weight.

[0052] Its preparation method is identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com