a lid that twists open

A technology of rotary opening and lid, applied in the field of containers, can solve the problems of user's hand pollution, poor sealing performance of the lid, inconvenient use, etc., and achieve the effects of simple structure, good sealing and leak-proof performance, and good sealing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

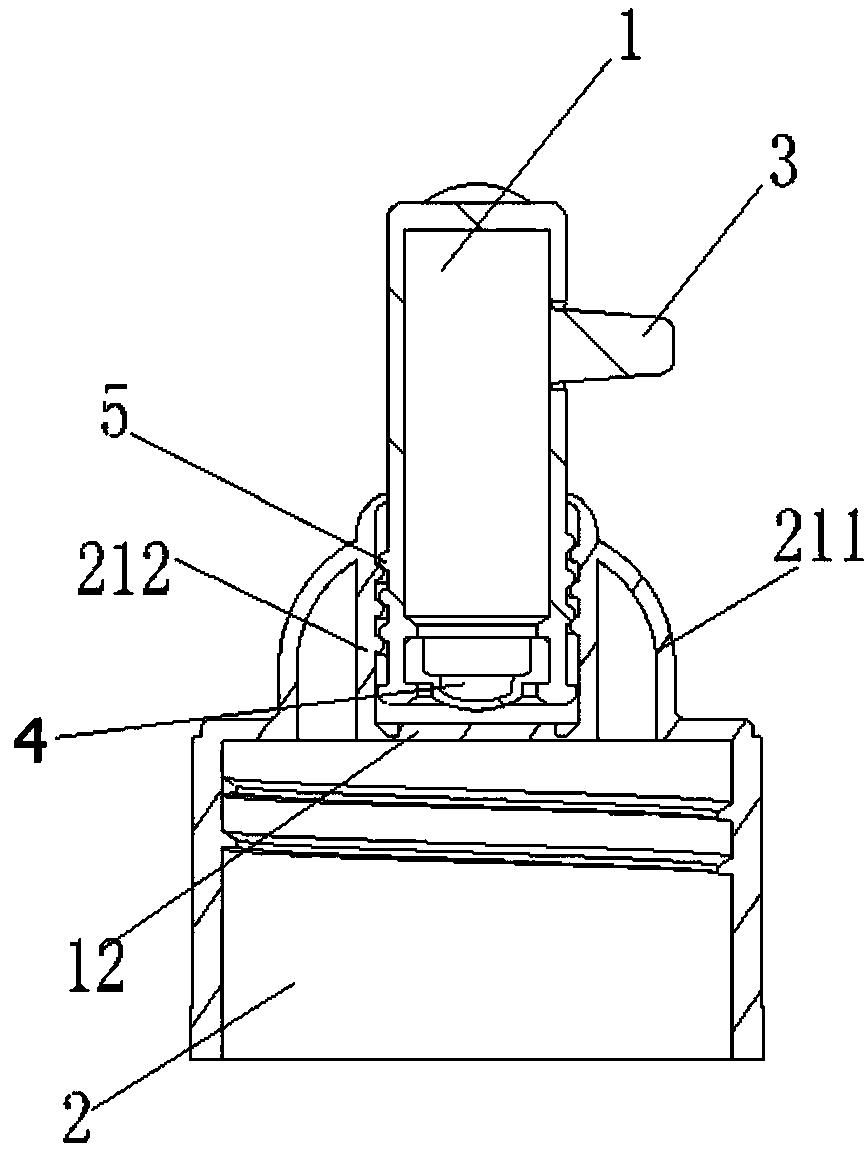

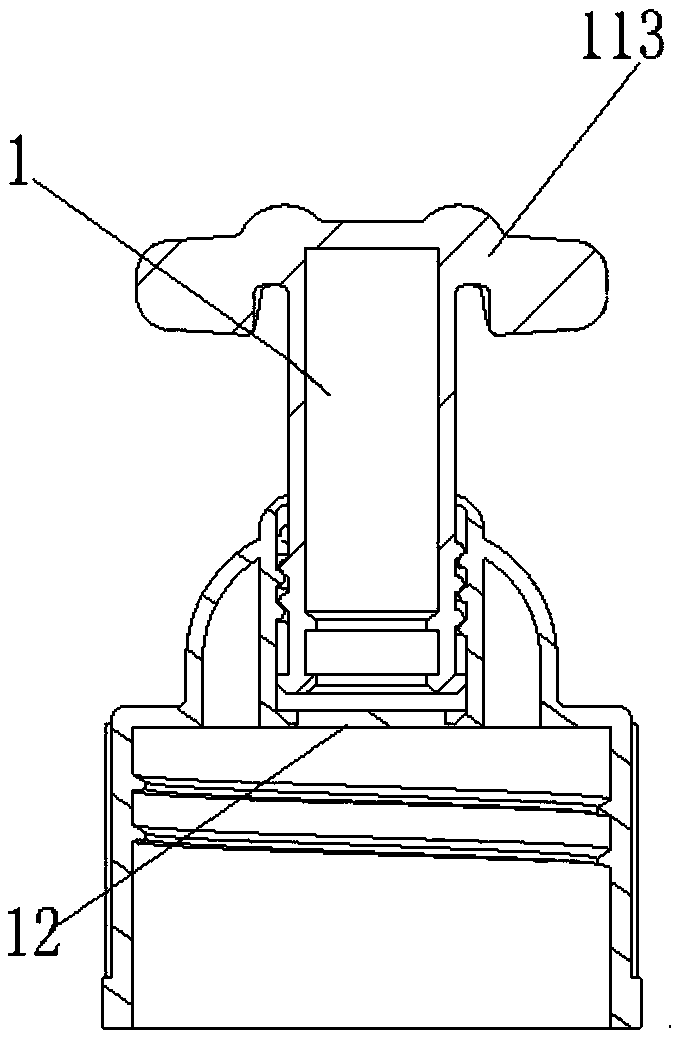

[0023] Embodiment one, such as figure 1 , 2 Shown; Provide a kind of cover that rotates to open, comprise the lower cover 2 that buckles or screw on the liquid outlet of container, described lower cover 2 has an upwardly arched shell 211, and the middle of arched shell 211 is set There is a tube body 212 protruding downwards, the upper end of the tube body 212 is a through hole, and a sealing piece 12 that can be opened downwards is integrally formed at the lower end of the tube body 212. Internal threads are provided on the inner wall of the tube body 212. Also includes a liquid outlet pipe 1, the outer circumference of the lower part of the liquid outlet pipe 1 is provided with an external thread 5 engaged with the internal thread, and the upper end of the liquid outlet pipe 1 extends from the upper through hole of the pipe body. Outlet, the upper side wall of the liquid outlet pipe is provided with a liquid outlet hole, the edge of the liquid outlet hole is integrally form...

Embodiment 2

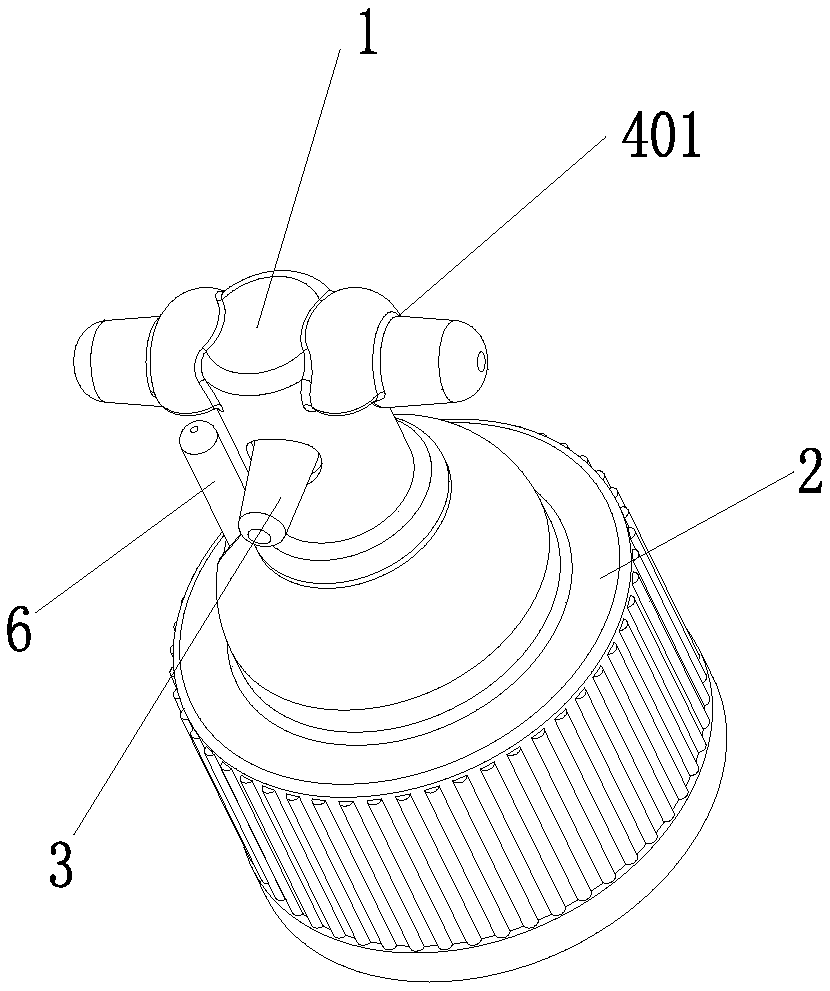

[0025] Embodiment two: if image 3 , Figure 4 , as shown, is on the structure of Embodiment 1, a groove can be provided at the bottom of the inner hole of the liquid outlet pipe 1, and a water outlet valve 4 that can be automatically opened under the action of pressure is provided in the groove to increase the water outlet. Valve 4 can prevent the liquid from flowing out automatically when the container is dumped. Only when the container body is squeezed, the liquid will flow out through the elastic water outlet valve. The structure and principle of the elastic water outlet valve have been disclosed and will not be described again.

Embodiment 3

[0026] Embodiment three: as Figure 5 , Figure 6 As shown, on the structure of Embodiment 1, an air inlet 201 is opened on the side of the arched shell 211, and a side of the pipe body corresponding to the air inlet 201 is provided with a An air supply valve 8 that can be automatically opened under pressure, adding an air supply valve 8 can make the liquid flow out more smoothly.

[0027] It is also possible to combine the features of the water outlet valve and the air supply valve in Embodiments 2 and 3. A groove is provided at the bottom of the inner hole of the liquid outlet pipe, and a water outlet valve that can be automatically opened under the action of pressure is provided in the groove. Valve; an air intake hole is opened on the side of the arched shell, and an air supply valve that can be automatically opened under pressure is provided on the side of the pipe body corresponding to the air intake hole. The cover also has the functions of replenishing air and preven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com