a lid that turns to open

A lid-integrated technology, applied in the field of containers, can solve the problems of poor sealing performance of the lid, contamination of the user's hands, inconvenient use, etc., and achieves the effects of simple structure, hygienic use, and good sealing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

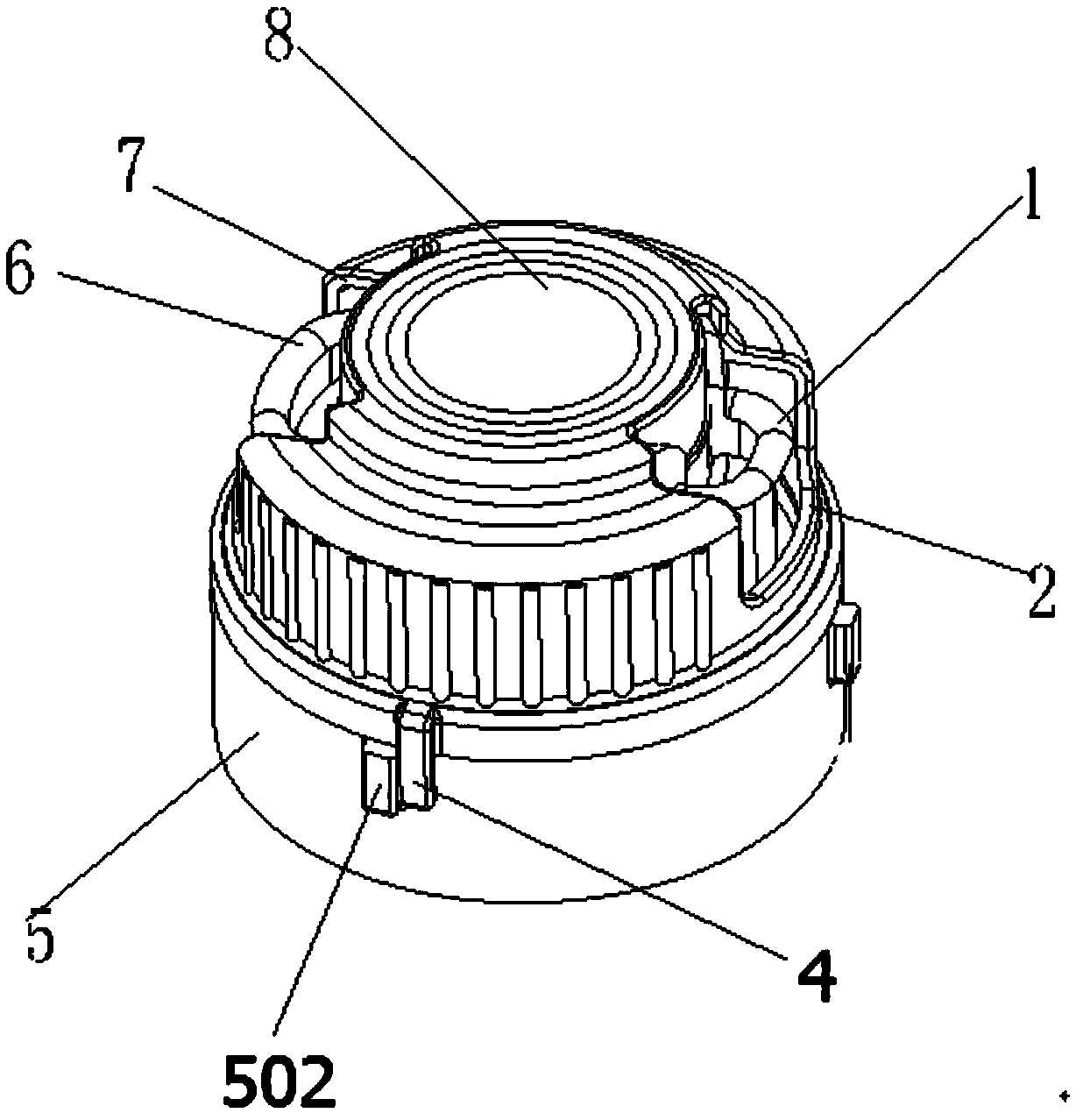

[0024] Embodiment one: refer to Figure 1-Figure 4 As shown: a cover that can be turned and opened is designed, including a lower cover 5 that is buckled or screwed on the liquid outlet of the container. The lower cover 5 has an upper platform, and an integrally formed one protrudes downward on the upper platform. The snap ring 501 used to engage with the inner hole of the container is integrally formed on the upper platform with a concentric outlet pipe 518 with a diameter smaller than the inner diameter of the snap ring. The upper part of the outlet pipe 518 is symmetrical There are two liquid outlet gaps 522, and an outwardly protruding liquid outlet nozzle 1, 6 is integrally formed on the edge of the two liquid outlet gaps 522, and the lower ends of the liquid outlet nozzles 1, 6 are connected with the upper The platform is integrally formed, and also includes an upper cover 8 that is fastened and connected with the buckle 519 on the platform of the lower cover and can rot...

Embodiment 2

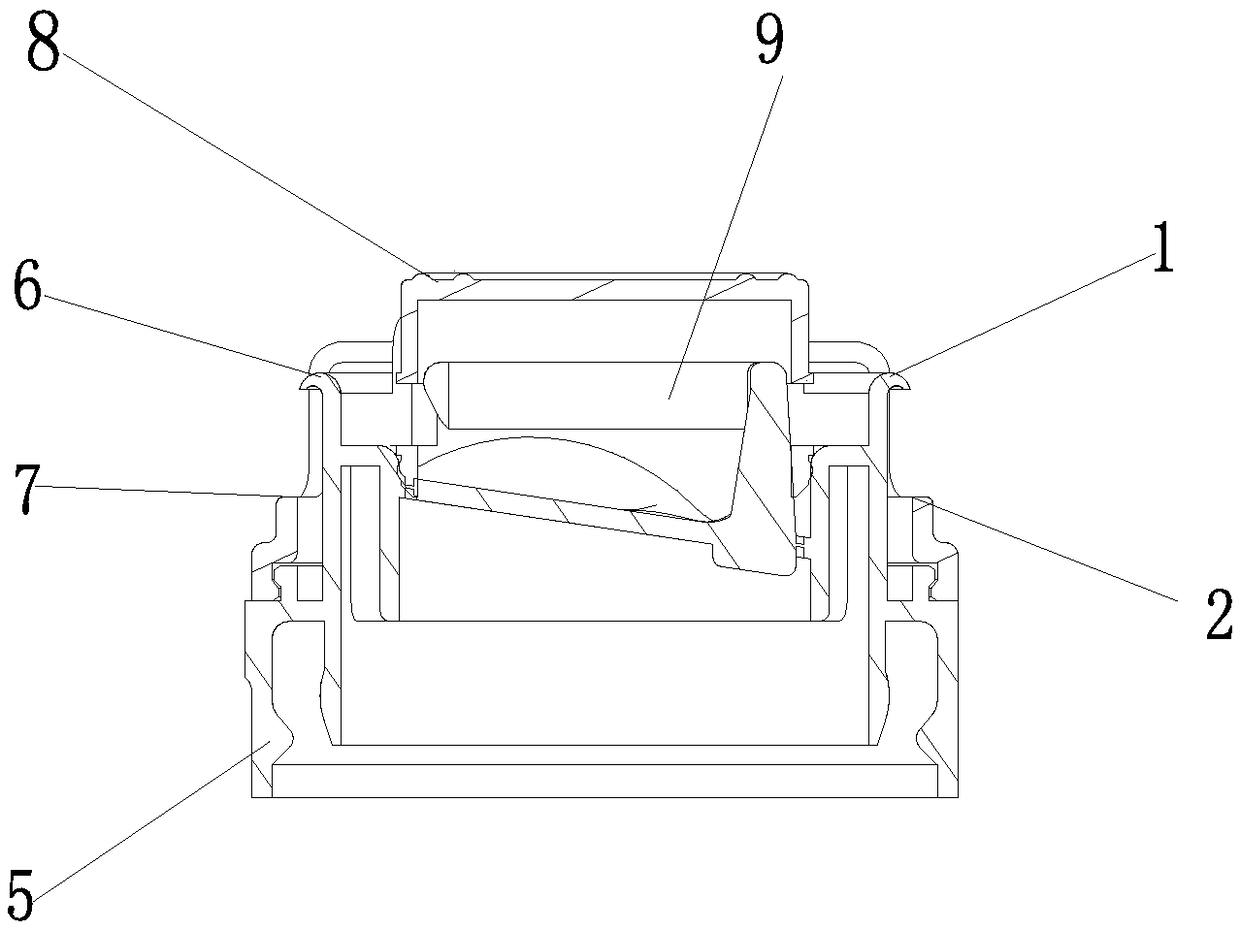

[0029] Embodiment two: refer to Figure 5-Figure 10 Shown: Design a cover structure that can be turned and opened, including a lower cover 5 that is buckled or screwed on the liquid outlet of the container. The lower cover 5 has an upper platform, and a downward Stretch out, used for the snap ring that is engaged with the inner hole of the container, and a liquid outlet pipe concentric with the snap ring is integrally formed on the upper platform, and the upper part of the liquid outlet pipe is symmetrically provided with two The liquid outlet nozzles 11, 12 also include an upper cover 8 that is fastened and connected with the buckle 519 on the platform of the lower cover and can rotate mutually. The body of the upper cover 8 is symmetrically opened with two The liquid outlet gaps 2, 7 corresponding to the liquid outlet nozzles are provided with a sealing tube 803 protruding downward at the center of the upper cover 8 and matching with the inner hole of the liquid outlet pipe....

Embodiment 3

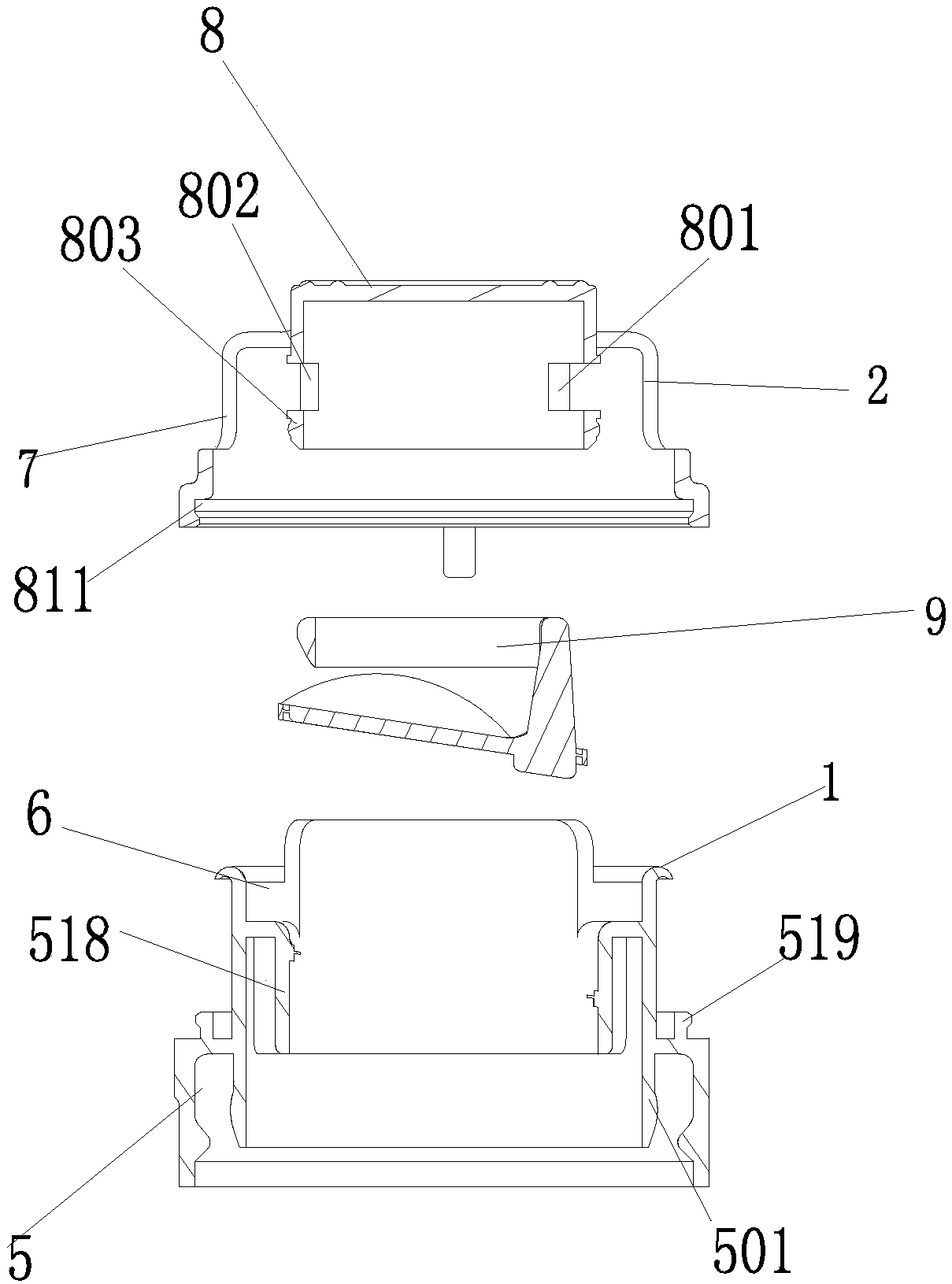

[0034] Embodiment three: refer to Figure 11-Figure 15Shown: Design a cover structure that can be turned and opened, including a lower cover 5 that is buckled or screwed on the liquid outlet of the container. The lower cover 5 has an upper platform, and a downward protruding platform is integrally formed on the upper platform. , a snap ring 501 for snapping into the inner hole of the container, and a concentric outlet pipe 518 with a diameter smaller than the inner diameter of the snap ring and concentrically formed on the upper platform, the upper part of the outlet pipe is provided with There is at least one liquid outlet gap, and a liquid outlet nozzle 511 protruding outward and having an elastic opening is integrally formed on the edge of the liquid outlet gap, and the lower end of the liquid outlet nozzle is integrally formed with the upper platform , also includes an upper cover 8 that is fastened and connected with the buckle 519 on the lower cover platform and can rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com