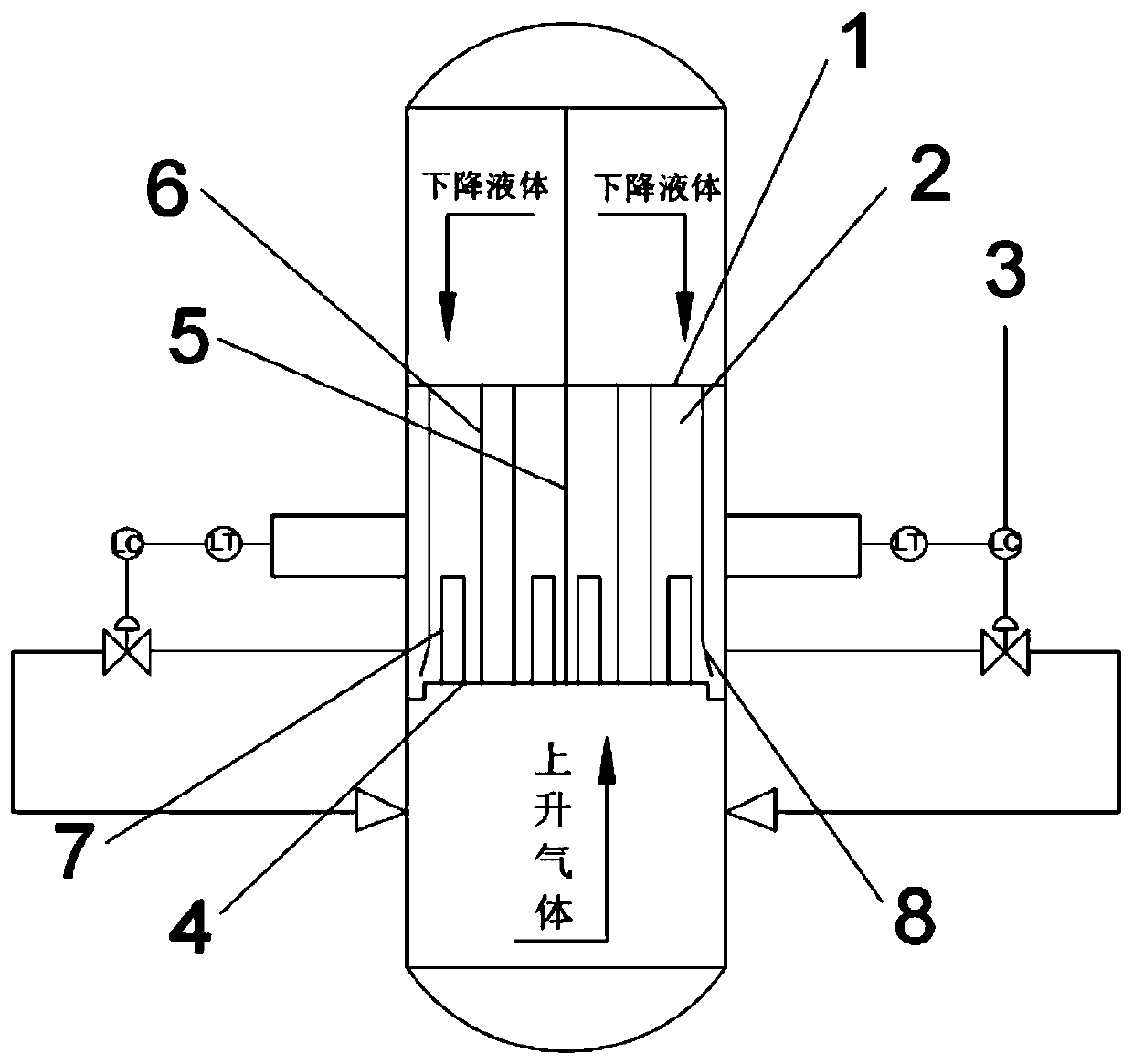

A gas phase distribution device

A distribution device, gas phase technology, applied in fractionation, distillation regulation/control, etc., can solve the problems of difficult to control the gas distribution of the clapboard column, unable to achieve the optimal operating condition of the clapboard column, uneven distribution of the clapboard column, etc. Simple and effective, easy to install and change, simple to install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

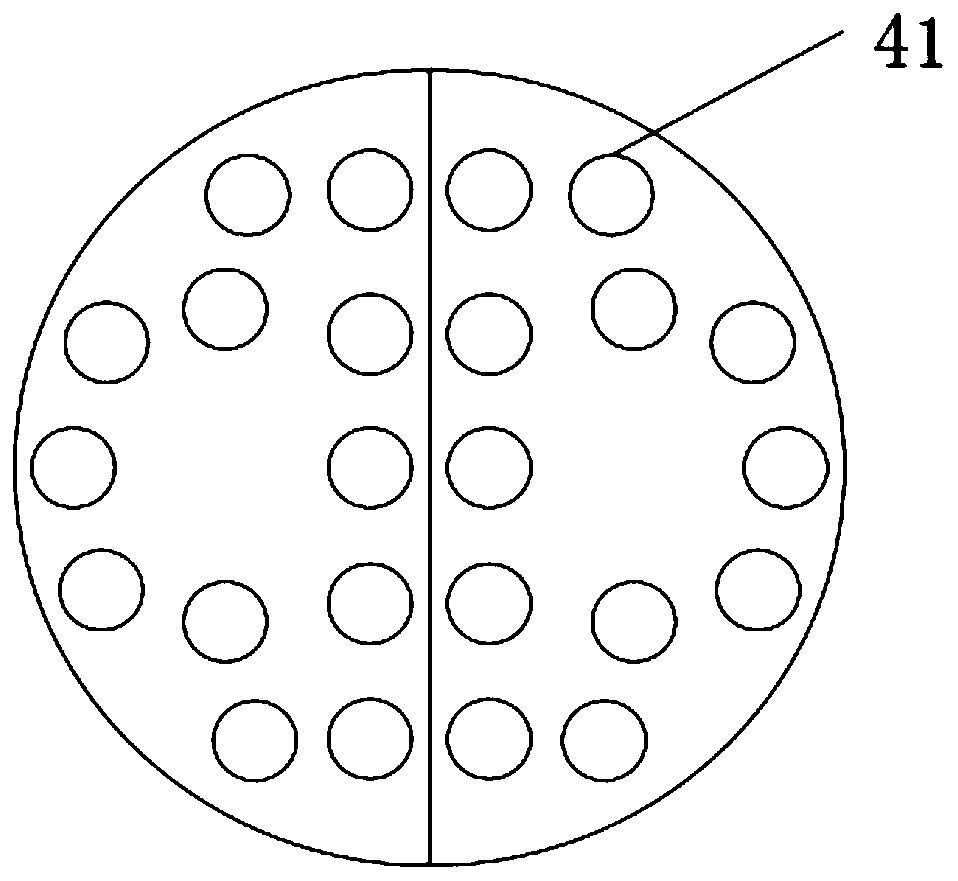

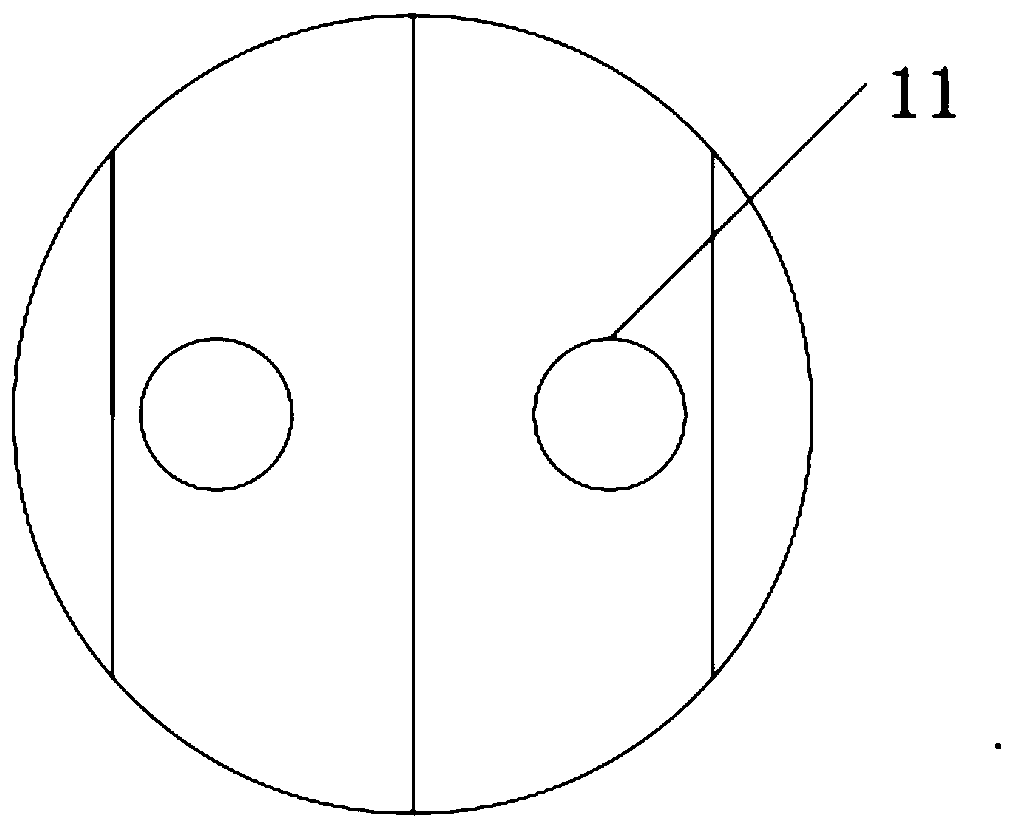

[0032] The gas phase distribution device of this embodiment is installed in a cold film partition tower with a diameter of 570mm. There are 24 openings for raising the gas on the gas-lifting pipe tray 4, each of which is a circular hole with a diameter of 50mm. The gas-lifting pipe on each gas-lifting hole is composed of a round pipe with a diameter of 50mm and a height of 300mm, and the gas-lifting pipe is welded at the corresponding opening; the diameter of the gas-lifting pipe is 100mm respectively welded on both sides of the partition, and the height of the gas-lifting pipe is the same as that of the gas-lifting pipe. The pressure drop regulating pipe 6 with the same height between the tray 4 and the pressure drop regulating plate 1, the lower part of the pressure drop regulating pipe 6 is closed and connected with the lift pipe tray 4, and the upper part is connected with the pressure drop regulating plate 1 through the pressure drop opening 11 The length of the long hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com