Nozzle head for a spray device

一种喷射装置、喷头的技术,应用在喷射装置、液体喷射装置等方向,能够解决大能量损失、失去作用、限制射束成形等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

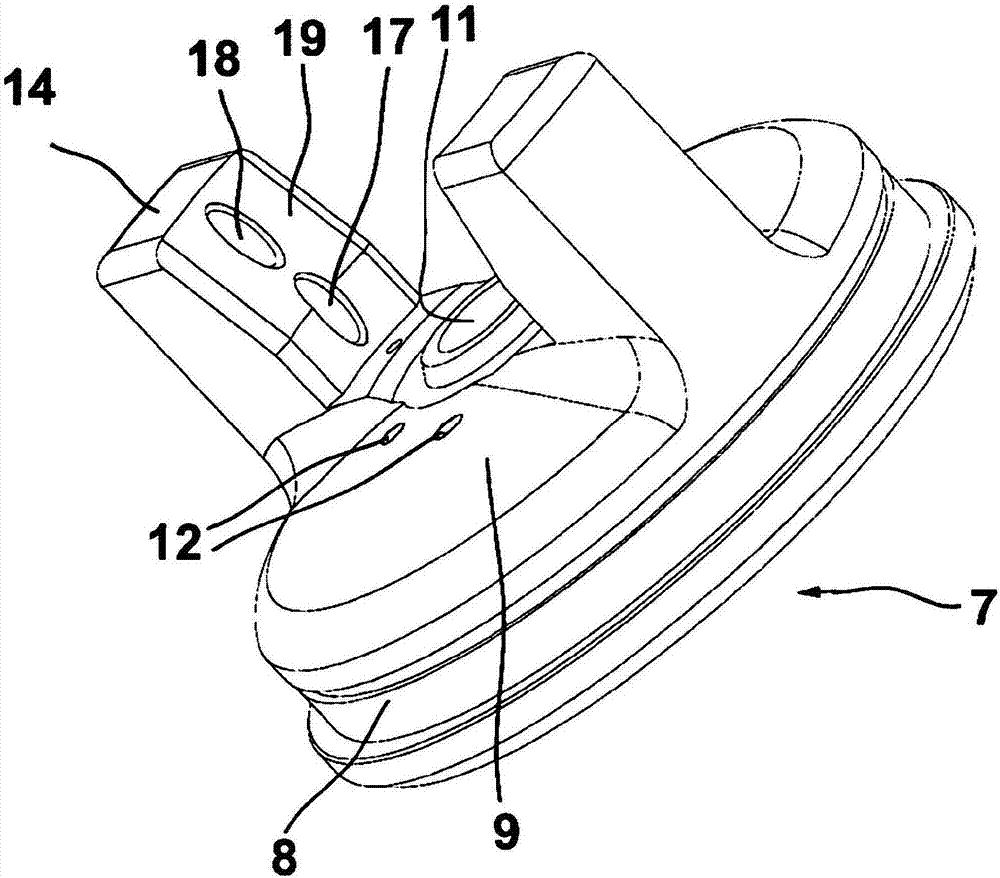

[0031] exist figure 1 and 2 The spray head for a paint spray gun shown in , has a paint nozzle body 1 with a substantially cylindrical paint channel 2 which opens centrally into a paint nozzle 3 . A hollow paint needle 4 is inserted into the paint nozzle 3 . The paint nozzle 3 is surrounded by an air ring nozzle 5 into which air can be supplied via a channel 6 . The air cap 7 is screwed onto the gun body by means of a ring 203, commonly referred to as an air nozzle ring. However, the gas cap 7 may also be fixed on the gun body by other means. In this embodiment, the air cap 7 is made by plastic injection molding. The gas cap has an annular section 8 which rests snugly against the gun body. A substantially planar cover plate 9 is connected to the annular section 8 . In the region of the so-called spout, the cover plate 9 has an annular bead 10 protruding from the planar region 9 , in the center of which an opening 11 emerges. When the paint nozzle 3 is mounted, the openi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com