3D printer for stamping die

A technology of 3D printers and stamping dies, applied in the field of 3D printing, can solve problems such as forced interruption, impact on the quality of 3D entities, and inability to complete the next printing task

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

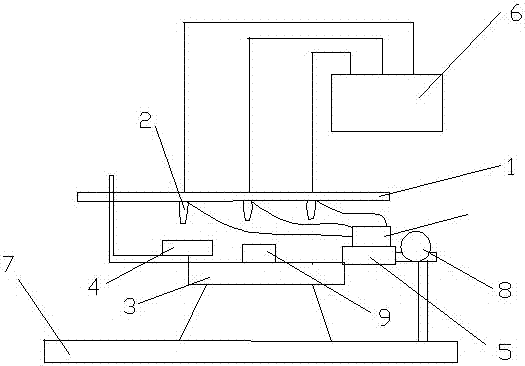

[0015] A stamping mold 3D printer, including X-Y working platform 1, nozzle 2, support table 3, mobile support frame 4, fixed support frame 5, printing box 6, base 7; the nozzle 2 and the mobile support frame 4 are installed On the X-Y working platform 1, the support table 3 is arranged on the base 7, and the nozzle 2 is connected to the print box 6; The consumables accommodated in the consumables accommodating part are provided to the nozzle 2 through the discharge port; the fixed support frame 5 is installed with a weight measuring device 8 for real-time detection of the consumables in the print box, and the consumables can be Quantitative real-time information is transmitted to the control center of the stamping die 3D printer; a pressure sensor 9 is provided between the support table 3 and the X-Y work platform 1; a photoelectric sensor device 10 is provided on the fixed support frame 5 , the photoelectric sensing device 10 is connected to the spray head 2; the pressure se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com