A kind of scraping device used on roller machine

A roller machine and scraping technology, which is applied in grain processing and other directions, can solve the problems of short scraper replacement cycle and reduced scraping ability, and achieve the effects of reducing wear, improving scraper life, and increasing effective force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

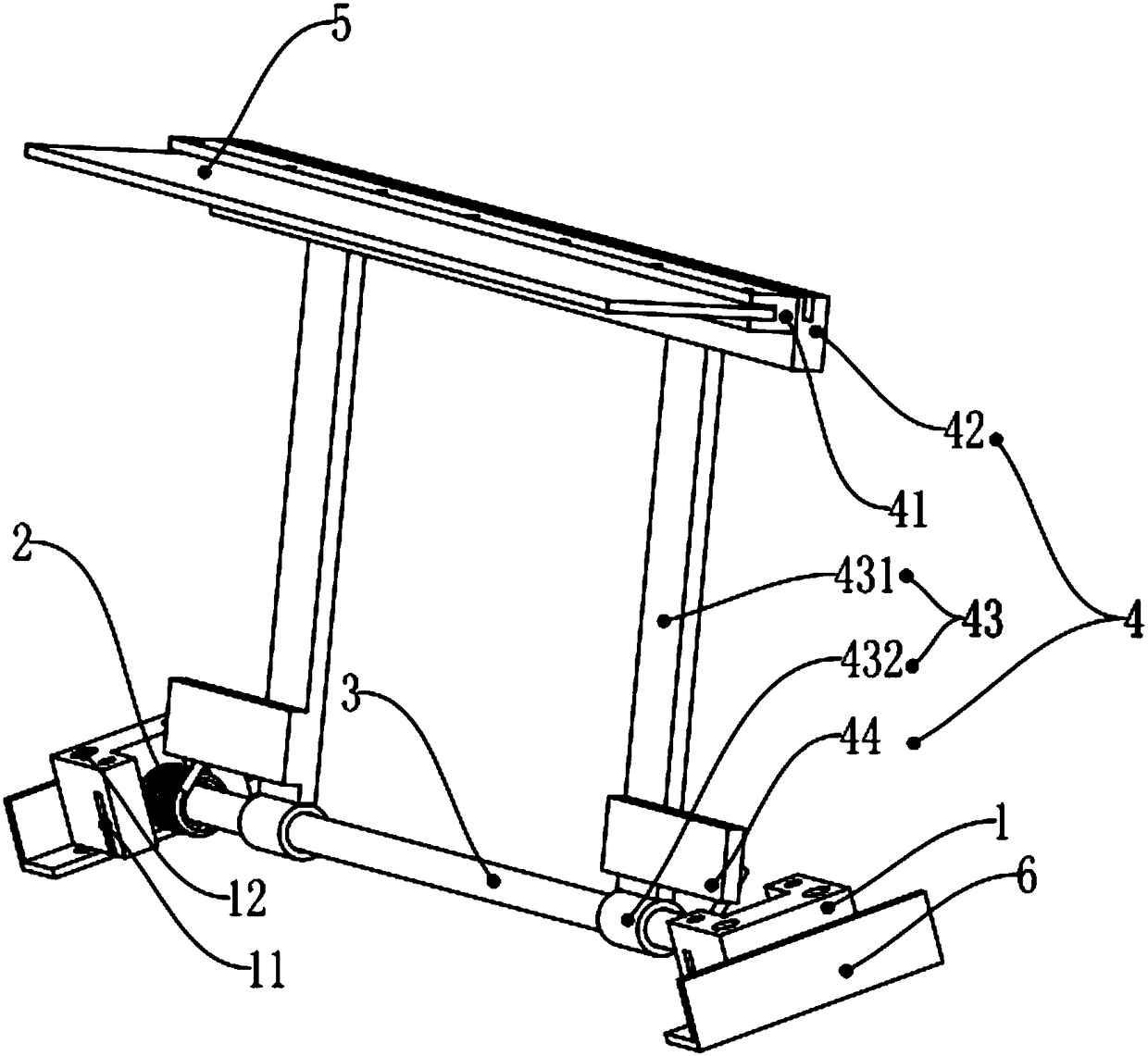

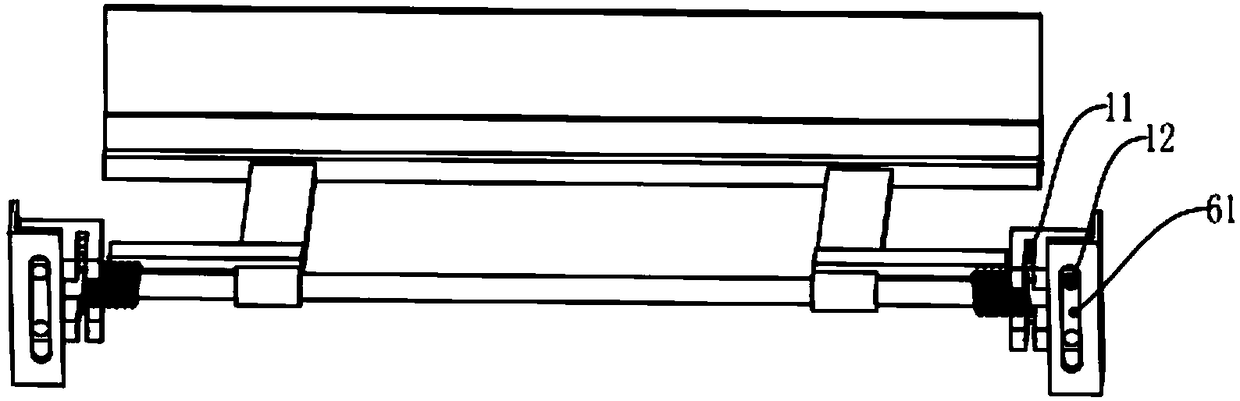

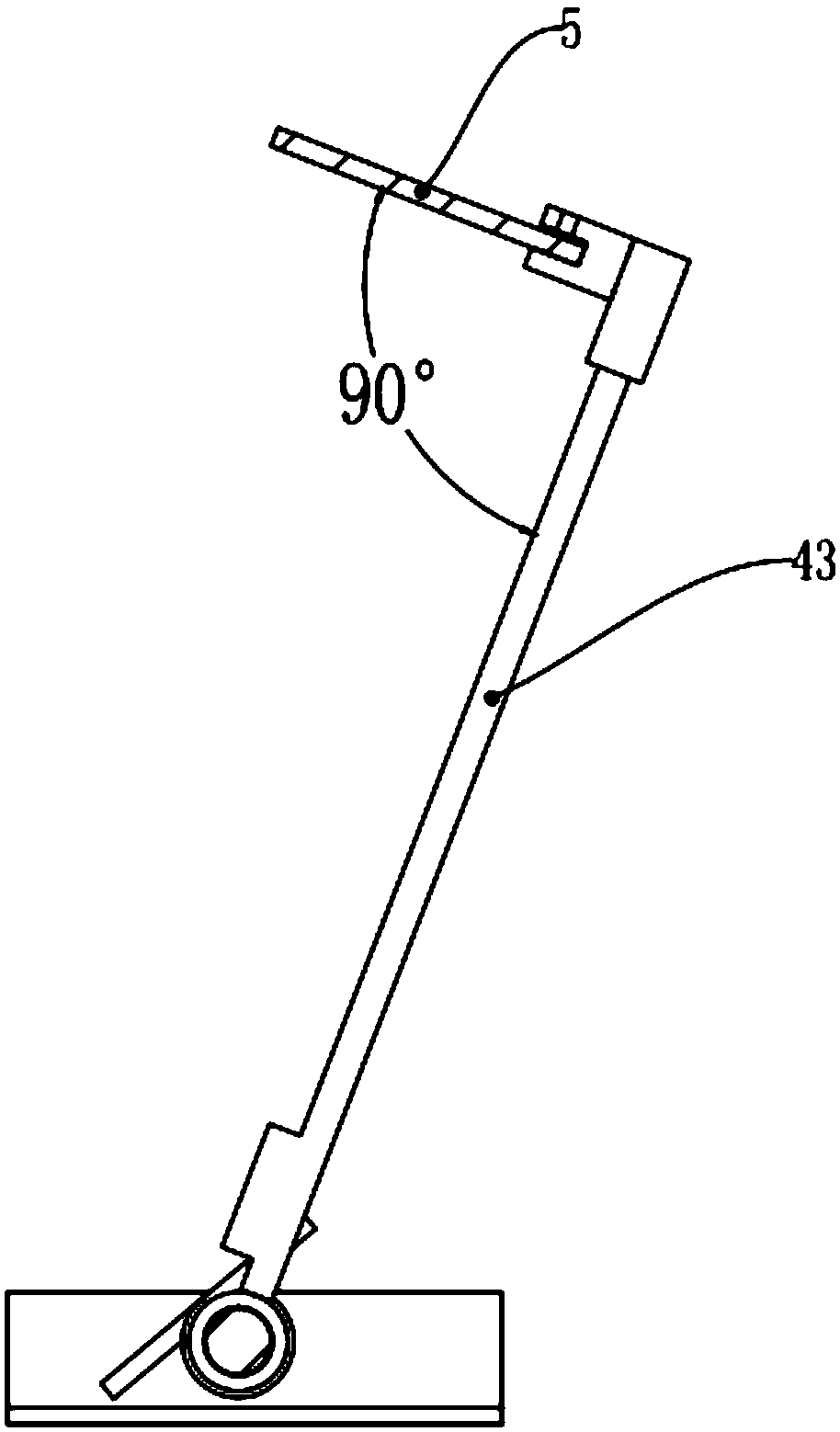

[0038] A scraping device for roller machines, comprising a base 1, a torsion spring 2, a rotating shaft 3, a scraper assembly 4 and a scraper 5; the base 1 is a concave structure, and the recesses of the base 1 are arranged oppositely, The recess of the base 1 is provided with a groove; the rotating shaft 3 is rotatably arranged in the groove of the recess of the base 1; the torsion spring 2 is provided with two, and the two torsion springs 2 are respectively sleeved on the rotating shaft 3 and located in the recess of the base 1; the torsion fulcrum of the torsion spring 2 is fixed on the base 1, one end of the torsion spring 2 is fixed on the base 1, and the other end is applied Torque is given to the scraper 5; the scraper assembly 4 is arranged on the upper part of the rotating shaft 3; the scra...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap