Fabricated connecting structure used for suspension type monorail traffic track beam and construction method

A monorail transportation and connection structure technology, applied in the field of rail transportation, can solve the problems of complex support structure design, low construction and installation efficiency, difficult installation and adjustment, etc. Effect of installation error and prevention of left and right shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

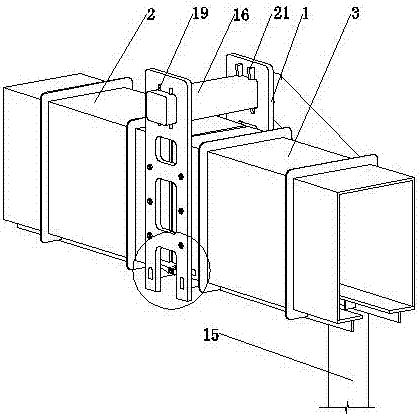

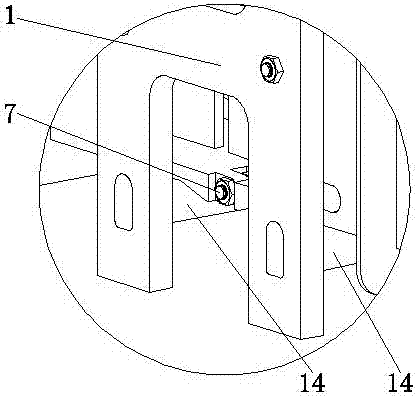

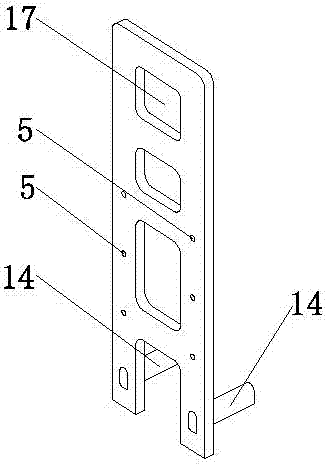

[0029] Such as Figures 1 to 9 As shown, the assembled connection structure for suspended monorail traffic track beams includes a bottom connection mechanism, a side connection mechanism and a support mechanism. The bottom connection mechanism realizes the stable and flat connection of the bottoms of the adjacent front and rear track beams 2 and 3 , the side connection mechanism realizes the stable and flat connection of the sides of the adjacent front and rear track beams 2 and 3, and the support mechanism realizes the overall stable support of the connected front and rear track beams 2 and 3 in the air at a certain distance from the ground, The side connection mechanism includes two side connection plates 1 symmetrically arranged on the left and right sides. After the cross-sections of the connecting ends of the adjacent front and rear track beams 2 and 3 are aligned...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com