Supercharging effect force-considering hole-wall collapsing pressure calculation method

A technology for wellbore collapse and stress effect, applied in the field of oil drilling, which can solve the problems of rising pore pressure near wellbore, difficulty in accurately predicting collapse pressure, and failure to consider effects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the technical solutions and advantages of the present invention clearer, the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

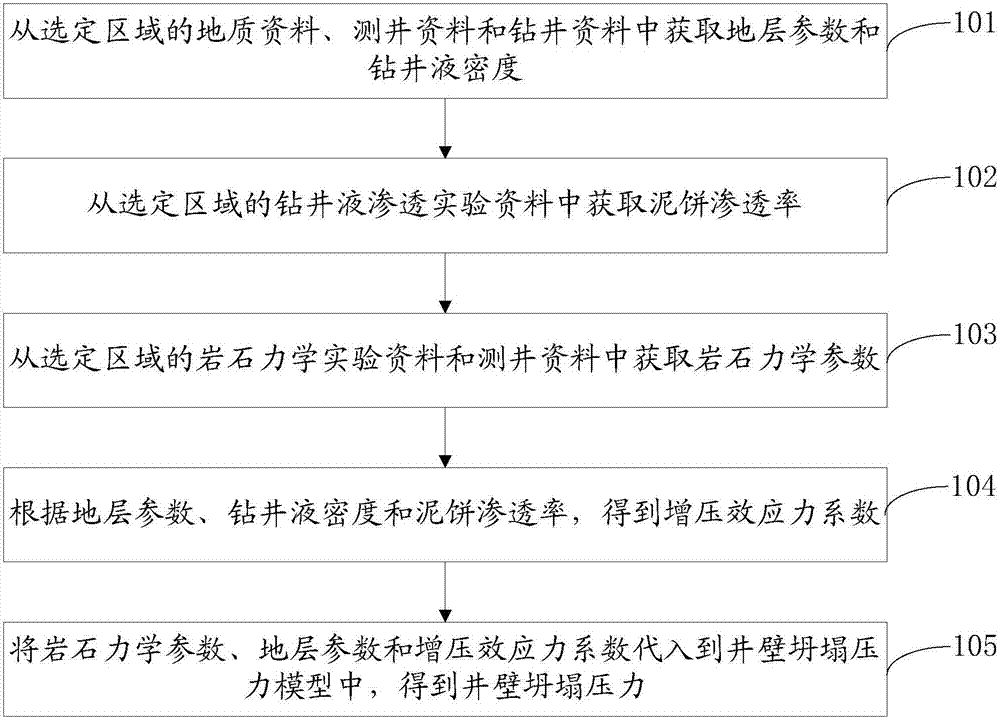

[0032] This embodiment provides a calculation method of wellbore collapse pressure considering pressurization effect stress, such as figure 1 As shown, the method includes:

[0033] Step 101: Obtain formation parameters and drilling fluid density from the geological data, logging data and drilling data of the selected area;

[0034] Specifically, formation parameters and drilling fluid density can be obtained from the geological data, logging data and drilling data of the selected area, which can be obtained by querying the formation data in the area or using measurement-while-drilling tools to directly detect during the drilling process, where , formation parameters include but not limited to: well depth, pore pressure, effective stress coefficient, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com