Self-controlled vertical type power distribution cabinet

A power distribution cabinet and electric power technology, which is applied in the direction of pull-out switch cabinets, electrical components, switchgear, etc., can solve problems such as the influence of power components, accidental contact with the wrong building, and time-consuming and labor-intensive pull-out, so as to reduce labor and The amount of labor, the effect of realizing the automatic locking connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

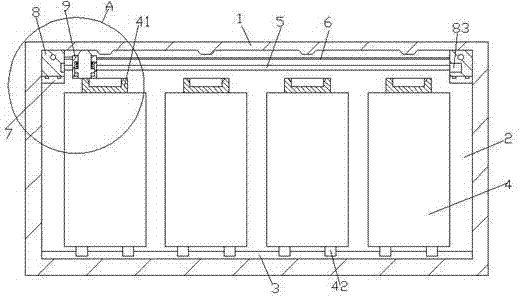

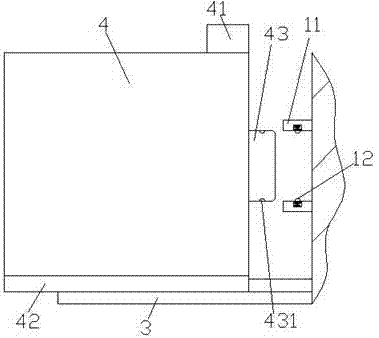

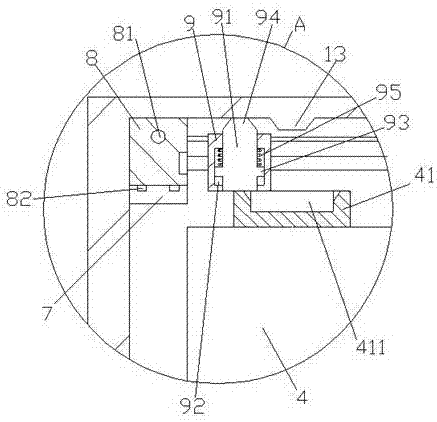

[0020] Such as Figure 1-Figure 4 As shown, a self-controlled vertical power distribution cabinet of the present invention includes a cabinet body 1, a housing chamber 2 is provided inside the cabinet body 1, and a first guide slide base plate 3 is provided at the bottom of the housing chamber 2, so that A plurality of equidistantly arranged drawer pieces 4 are arranged above the first slide guide bottom plate 3, and the bottom of each drawer piece 4 is provided with a first sliding fit connection arranged in the first slide guide bottom plate 3. Guide slide bar 42, each said drawer piece 4 top rear side edge is provided with insert block 41, and said insert block 41 is provided with insert groove 411 inside, and described cabinet body that said insert groove 411 is opposite 1. The inner top wall is provided with inclined-plane convex strips 13 extending forward and backward along the inner top wall of the cabinet body 1, and the upper left and right sides of the accommodating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com