Steel material, and oil-well steel pipe for expansion

A technology of steel and steel pipes, applied in the field of oil well steel pipes for pipe expansion, can solve the problems of unfavorable economy, wider excavation area, large excavation cost and construction period, etc., and achieves excellent pipe expansion, high uniform elongation, and excellent SSC resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

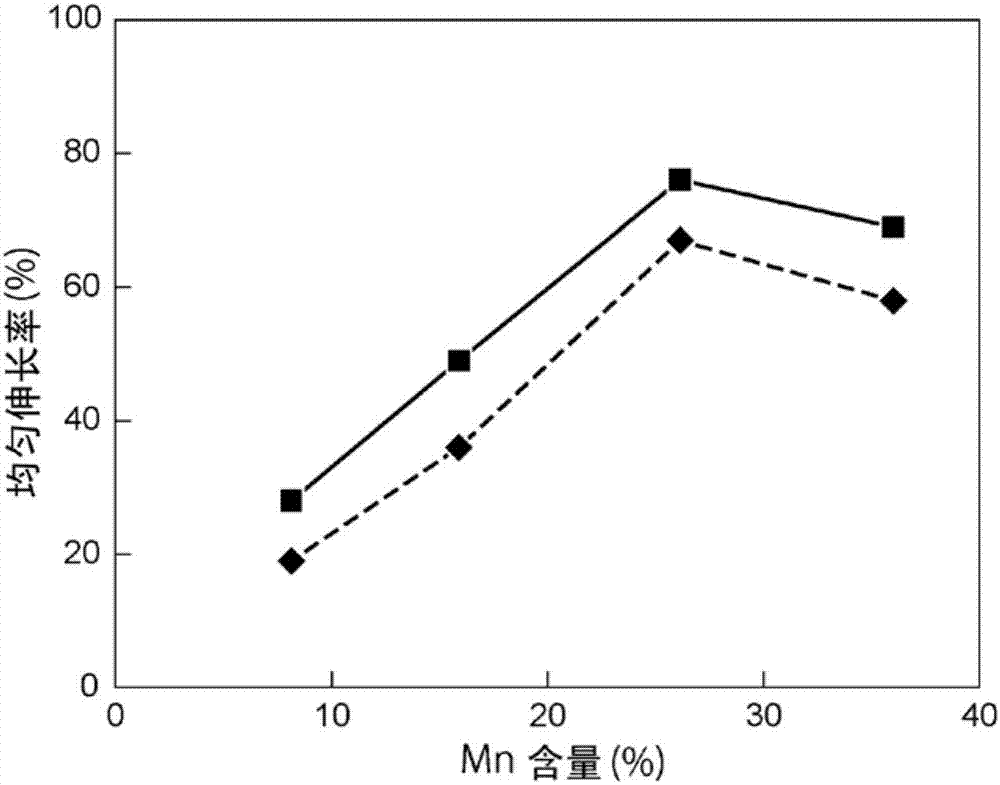

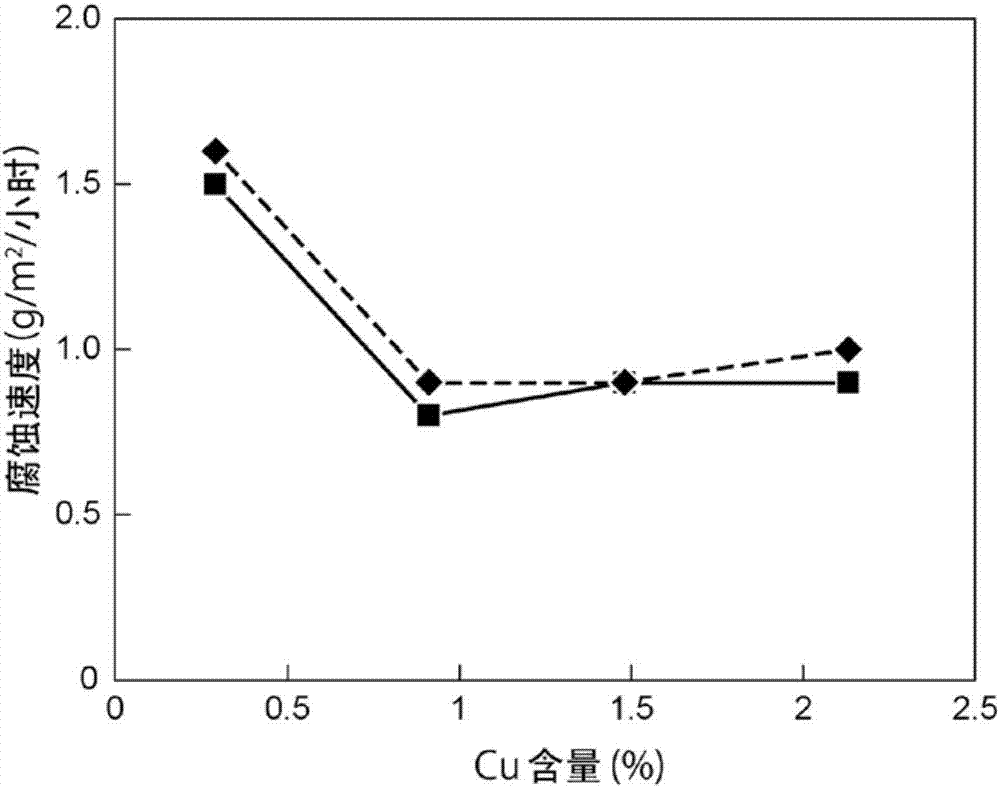

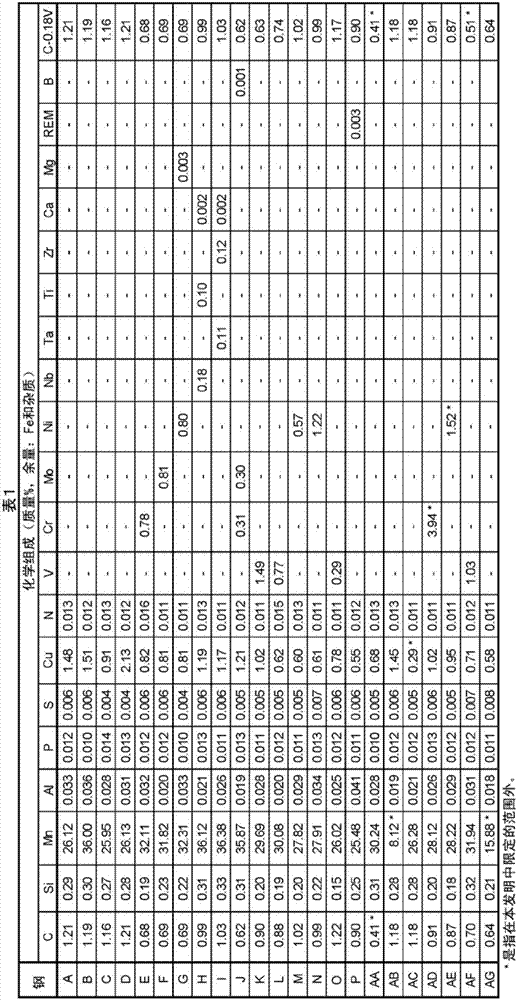

[0149]In a 50 kg vacuum furnace, 23 kinds of steels, A to P and AA to AG having the chemical compositions shown in Table 1, were melted and cast into steel ingots. Each steel ingot was heated at 1180° C. for 3 hours, then forged, and cut by electric discharge cutting. Thereafter, soaking was performed at 1150° C. for 1 hour and hot rolling was performed to form a plate material with a thickness of 20 mm, and then solution heat treatment was performed at 1100° C. for 1 hour to obtain test materials (test numbers 1 to 23). In addition, the test materials produced in the same manner as test numbers 1 to 23 were further subjected to cold working with a working degree of 10% after the solution heat treatment to obtain test materials with improved strength (test numbers 24 to 46).

[0150] [Table 1]

[0151]

[0152] After examining the mechanical properties and metallographic structure of the above-mentioned test materials (Test Nos. 1 to 46), each test material was subjected t...

Embodiment 2

[0176] Using steels K, L, O, and AF prepared in Example 1, the influence of aging heat treatment after solution treatment was investigated. The conditions of the solution heat treatment were the same as in Example 1, and the conditions of the subsequent aging heat treatment were 800° C. for 1 hour. In addition, the method of the evaluation test is the same as that of Example 1.

[0177] As for the metallographic structure after the above-mentioned aging heat treatment, similarly to Example 1, the test materials before and after cold working with a working degree of 25% were investigated using a ferrite measuring instrument. As a result, for the test material before cold working, the BCC structure structure was not detected in any sample, and it was an austenite single phase. Therefore, in the table, only the volume amount of the structure having the BCC structure of the cold-worked test material is shown in volume % in the form of the BCC ratio. These results are shown in Ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com