Method for producing an electrical line, tool mould for such a method, and line

A technology of cables and moulds, applied in earphone cables/cable storage, household appliances, insulated cables, etc., can solve problems such as unsatisfactory design solutions and expensive methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

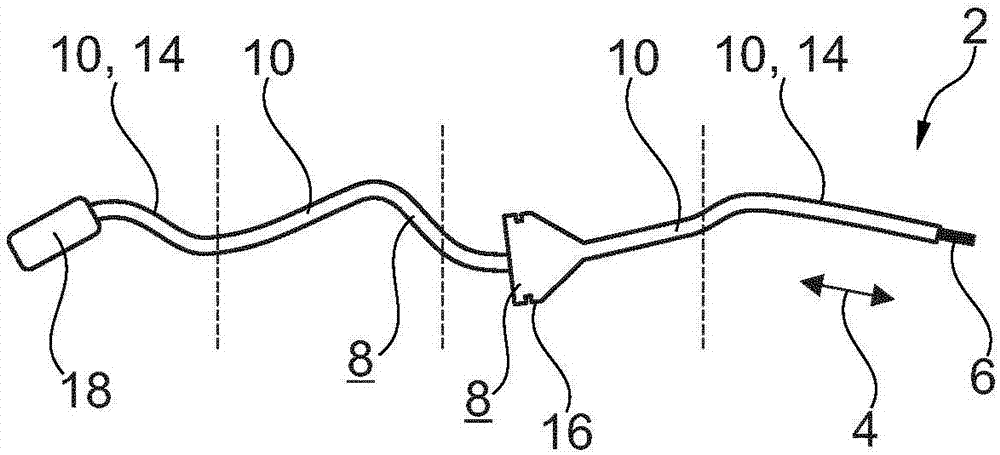

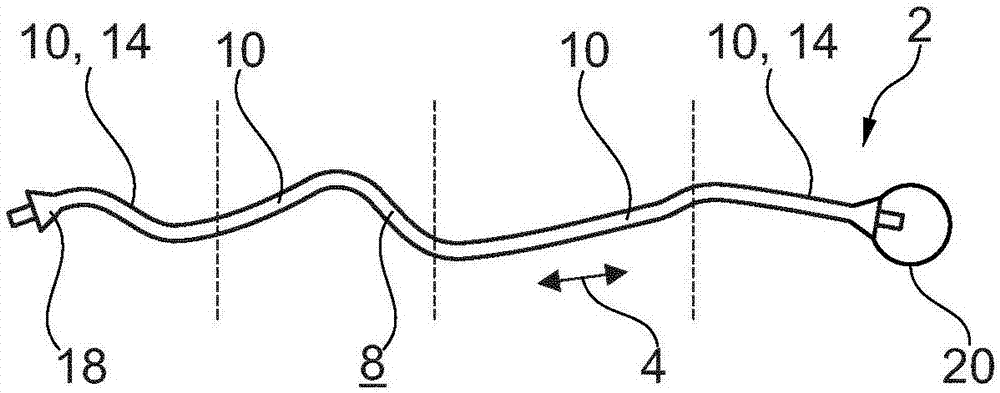

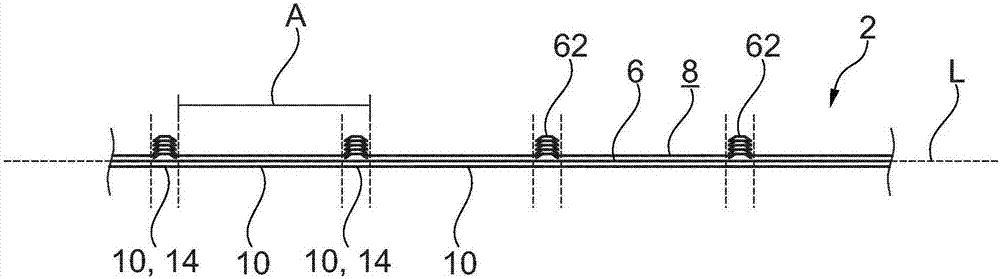

[0053] figure 1 and 2 The shown cables 2 each extend in the longitudinal direction 4 of the cable and comprise a cable core 6 which is surrounded by an outer sheath 8 . The outer jacket 8 is formed here from individual jacket sections 10 which directly adjoin each other. In the final produced state, the sheathing sections 10 cannot be individually identified due to the special molding method described later, ie the areas where the individual sheathing sections 10 adjoin each other are not discernible.

[0054] The outer sheath 8 is a protective or insulating sheath, usually constructed of a hardenable plastic polymer substance. The cable core 6 is one or more electrical conductor cores 12, which exist, for example, as bundled individual cores or also as coaxial wires or the like. The cable core 6 may also have a complex structure composed of different cable components. In this case, optical transmission fibers and / or other components can also be integrated into the cable c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com