Lens holder and method of use

A technology of holder and lens, applied in the direction of instruments, lenses, applications, etc., can solve problems such as difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

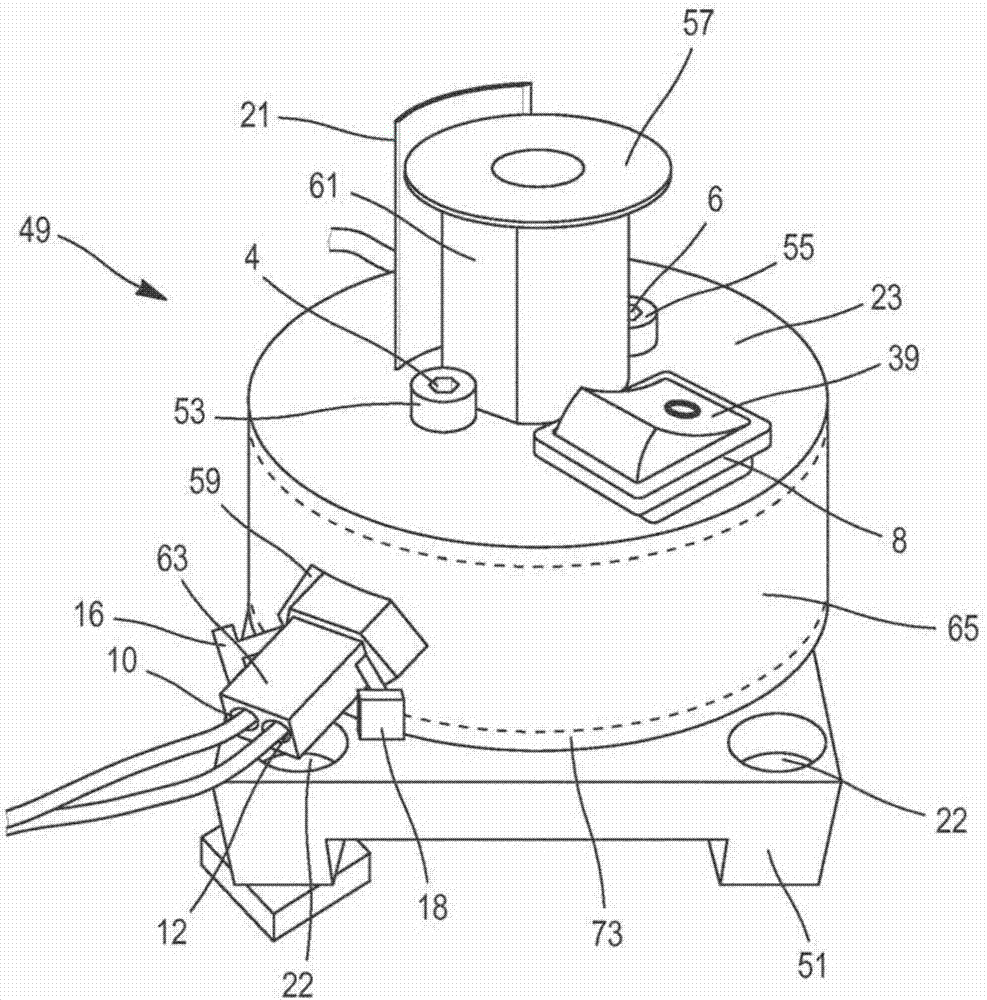

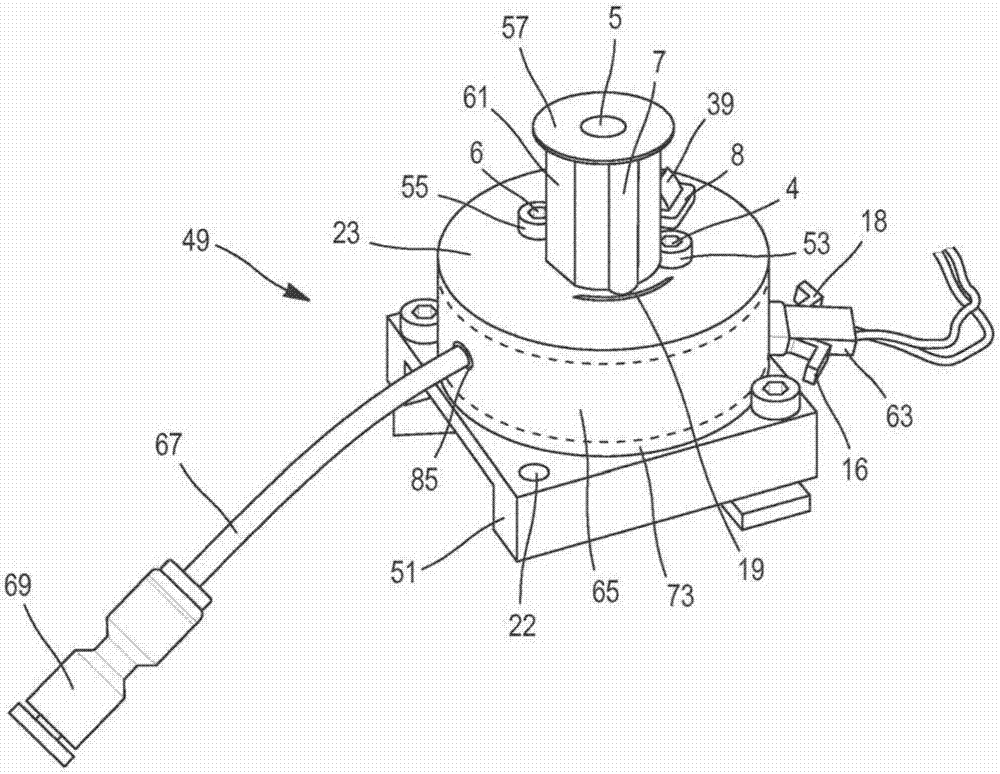

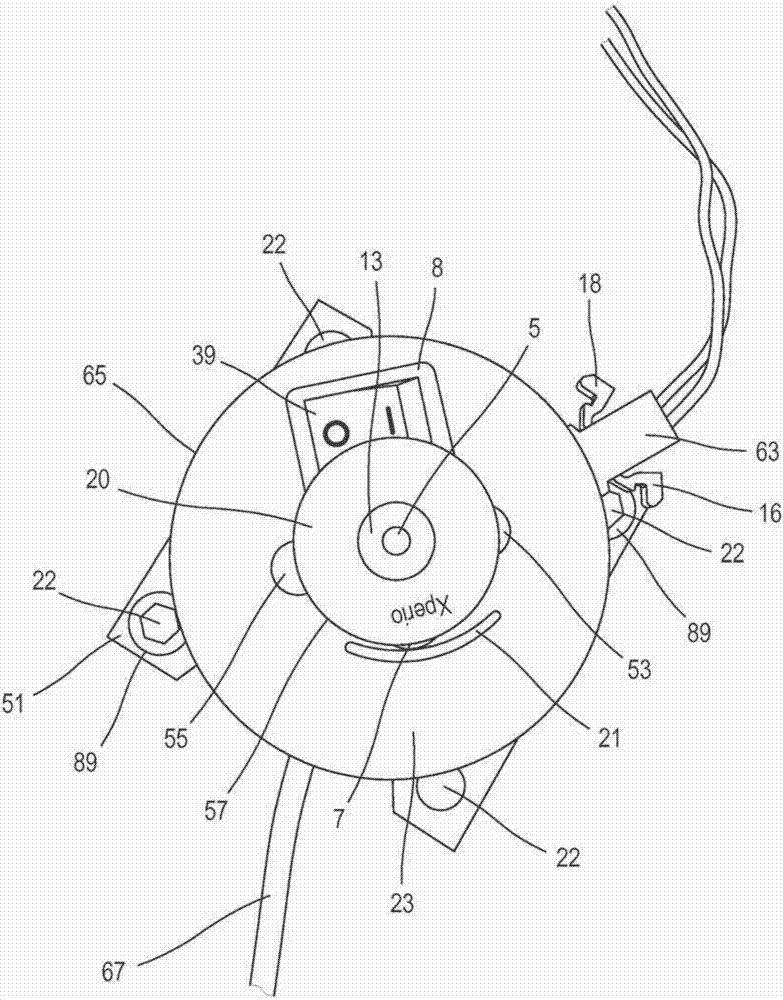

[0023] A lens holder device and method of marking an ophthalmic lens using a lens holder is presented herein. This improved device and method allows the user to consistently orient and position the lens on the lens holder to achieve marking at the desired location while reducing user error and the chance of incorrectly marking or damaging the lens, This saves time and reduces manufacturing costs.

[0024] Other objects, features and advantages of the present disclosure will become apparent from the following detailed description. It should be understood, however, that the detailed description and specific examples, while indicating particular embodiments of the invention, are given by way of illustration only, since various changes and modifications within the spirit and scope of the invention will be apparent from such detailed description. It will become apparent to those skilled in the art. Unless the scope is expressly and clearly defined in this disclosure or unless the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap