Method and device for loading a loading surface

A loading device and loading technology, applied in the directions of loading/unloading, transportation and packaging, etc., can solve problems such as unloading, achieve flexible use, low complexity, and reduce physical load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

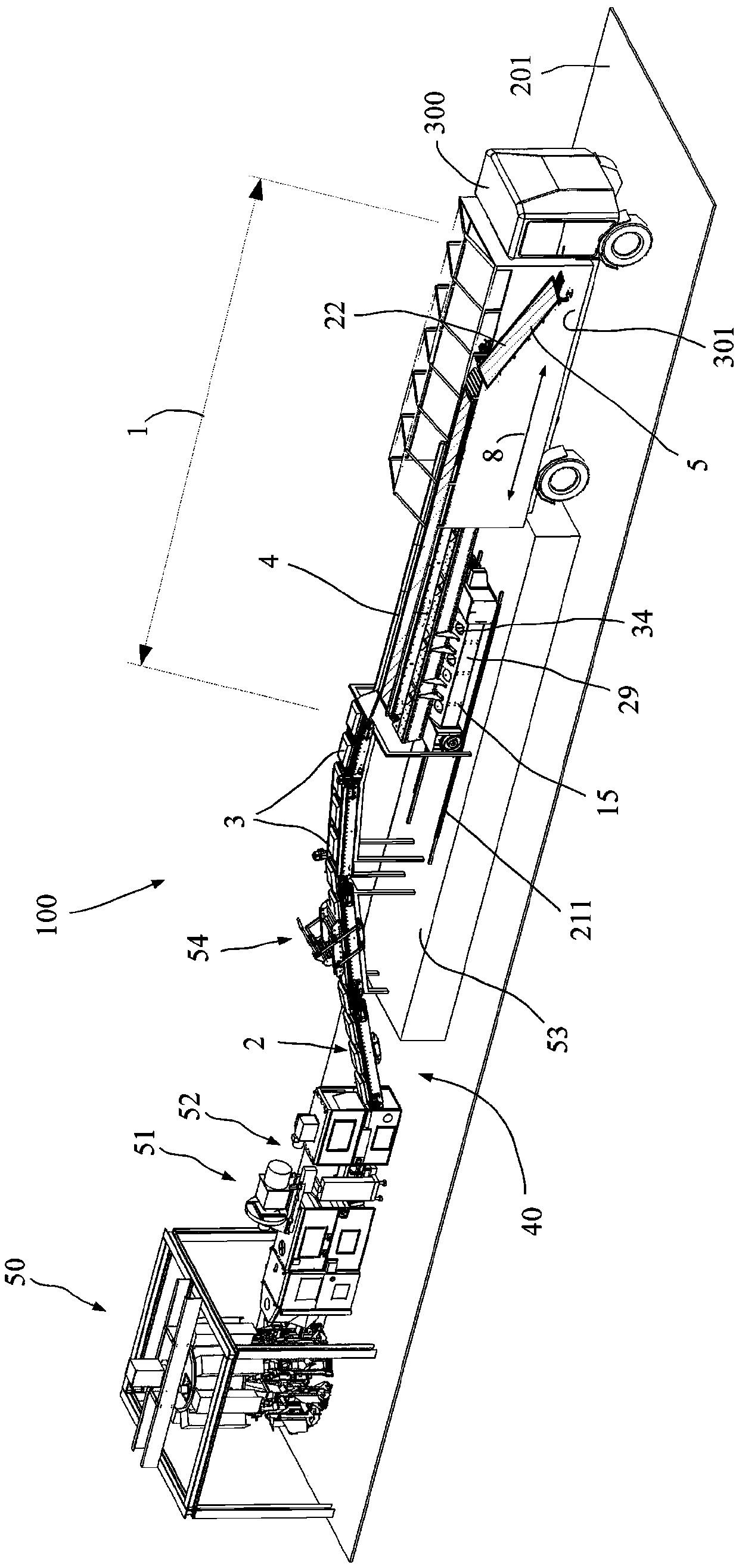

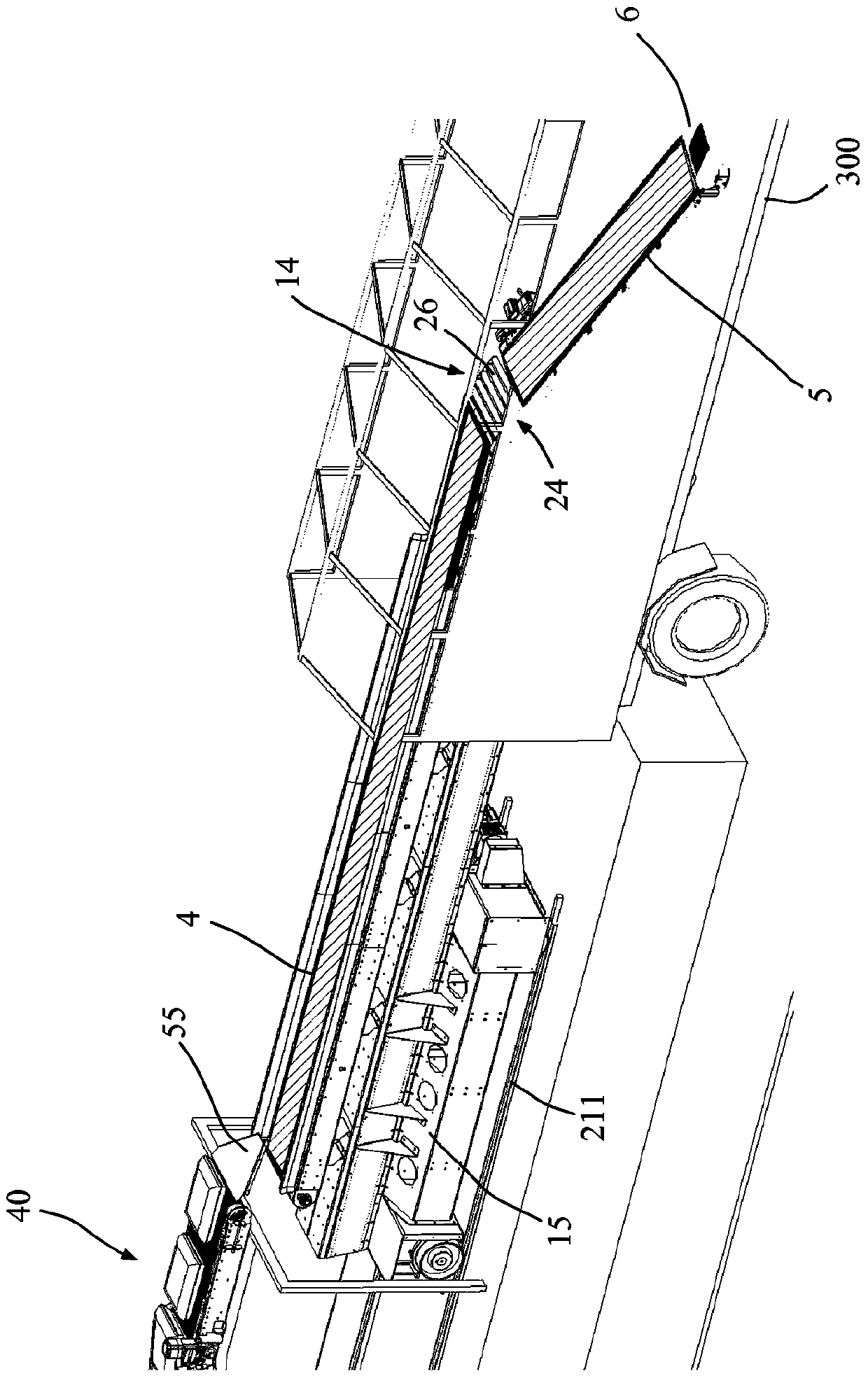

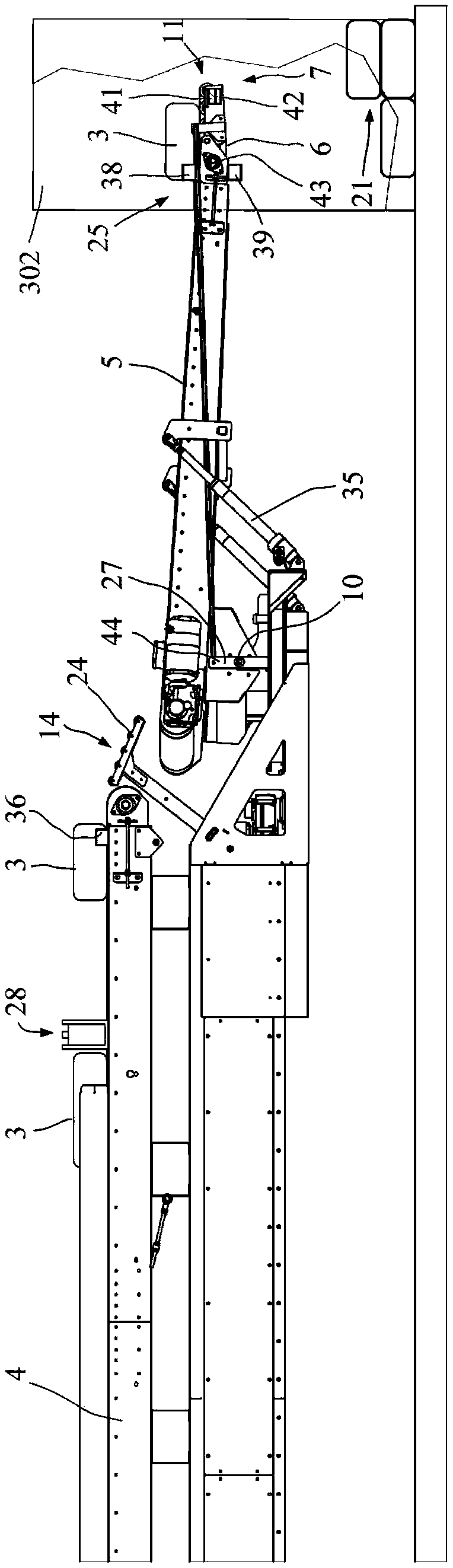

[0059] figure 1 is a perspective view of a packaging apparatus 100 for filling and filling eg cement in flexible bags. However, the packaging apparatus 100 in the form shown can be applied to vastly different types of shipments and bulk materials or fluids contained in containers or bags.

[0060] The packaging plant 100 comprises a packaging machine 50 which here comprises 8, 10, 12 or 16 filling nozzles dispersed around it and which rotates during operation and during which the bulk material to be filled is filled into the goods 2 as goods 2. Inside bag 3. The bags are fed to the packaging machine 50, for example at an angular position, by means of a bag inserting device not shown and inserted onto the filling spout.

[0061] After filling the bags 3 as goods 2 , the filled bags are unloaded and sent to a cleaning station 51 . This is followed by a checkweigher 52 which can be placed, for example, on a conveyor belt to selectively weigh the goods 2 during transport as req...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com