Device for removing crease for leather shoe upper

A technology for shoe uppers and leather shoes, applied in the direction of shoemaking machinery, application, footwear, etc., can solve the problems of increasing scrap rate, low leveling efficiency, worse leveling effect, etc., to avoid damage, improve efficiency, and avoid damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

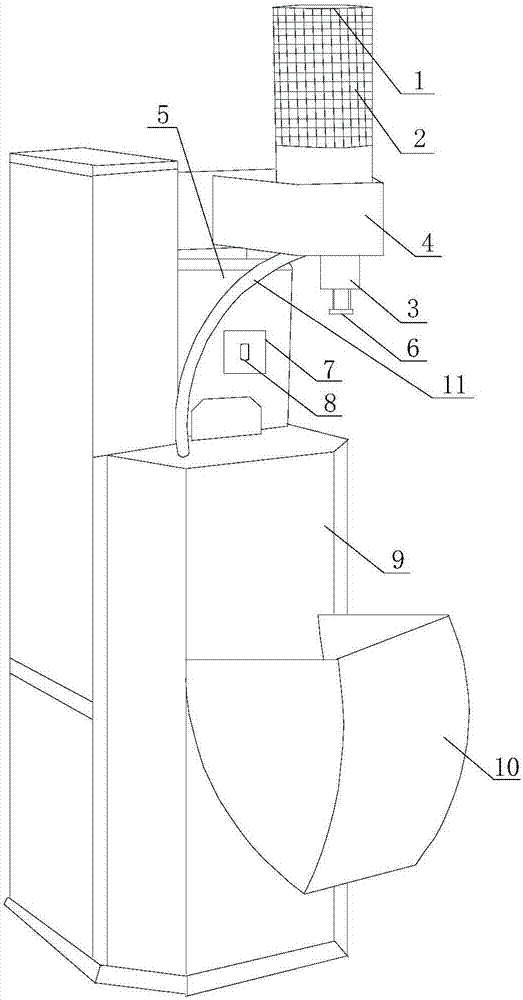

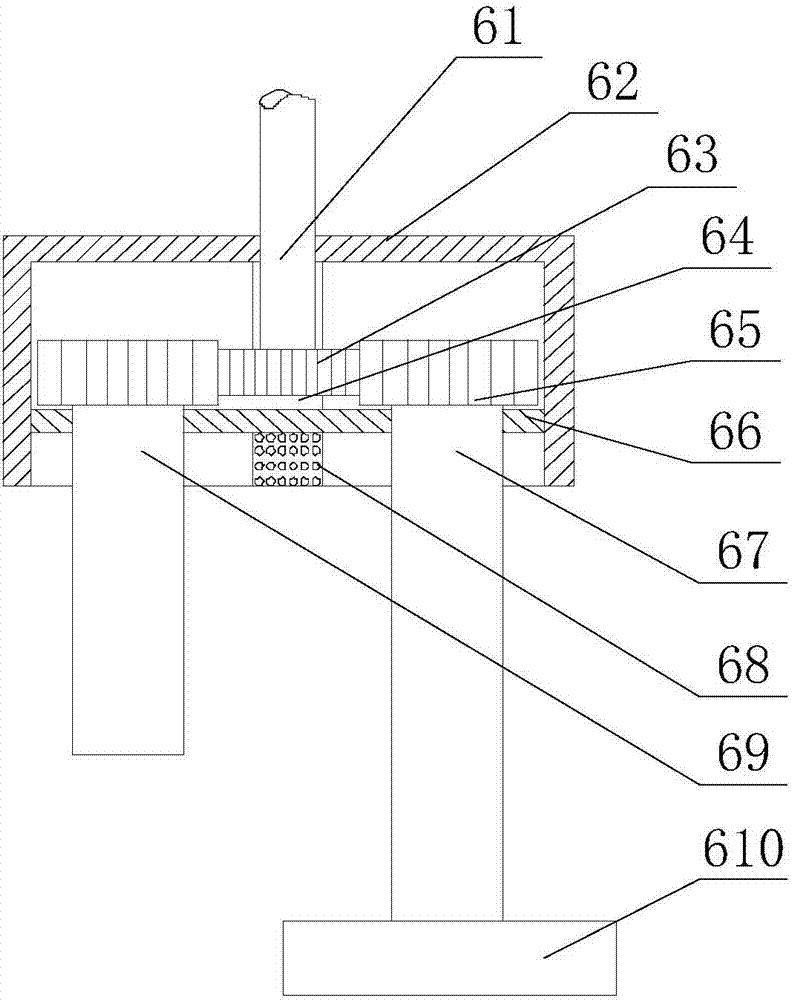

[0022] Such as Figure 1~2 As shown, the present embodiment includes a body 9 and a mounting seat 4 and a water tank 5 fixed on the side wall of the body 9. A fan, a motor, and an air intake pipe 1 are arranged at the upper end of the mounting seat 4, and a flat surface is provided at the lower end of the mounting seat 4. Component 6 and water tank 5, the air inlet pipe 1 communicates with the air intake end of the fan, and the output end of the motor moves through the mounting seat 4 and then links with the leveling component 6. A conduit 11 is provided on the side wall of the water tank 5, and the conduit 11 The end of the atomizer is provided with an atomizer; a collection frame 10 is also fixedly arranged on the body 9, and the frame opening of the collection frame 10 is directly below the leveling assembly 6; Facing the cylinder 62 on the horizontal plane, one end of the rotating shaft 61 is connected to the output end of the motor and the other end moves through the hori...

Embodiment 2

[0025] Such as Figure 1~2 As shown, in this embodiment, a temperature sensor 7 and an alarm 8 connected to each other are provided on the water tank 5 , the temperature sensor 7 is placed inside the water tank 5 , and the alarm 8 is placed outside the water tank 5 . Due to the high requirements of the wrinkle removal process, it takes a lot of time to process and requires a large amount of water in the water tank 5 . When the water level in the water tank 5 is low, the temperature sensor 7 set in the water tank 5 transmits the water level information to the alarm 8, and the alarm 8 sends out a prompt alarm in time, and the operator replenishes the water in time, avoiding the accident caused by insufficient water. The empty consumption of the atomizer is helpful to maintain the equipment and improve the efficiency of the equipment.

[0026] As preferably, the extension of the air outlet pipe 64 is placed between the first roller 67 and the second roller 69, so that the hot ai...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap