Micro-nano bubble spray head

A technology of micro-nano bubbles and nozzles, applied in the direction of injection devices, liquid injection devices, etc., can solve the problems of low investment, high purification efficiency, and low operating cost, and achieve the effect of consistent jet direction and uniform spraying ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

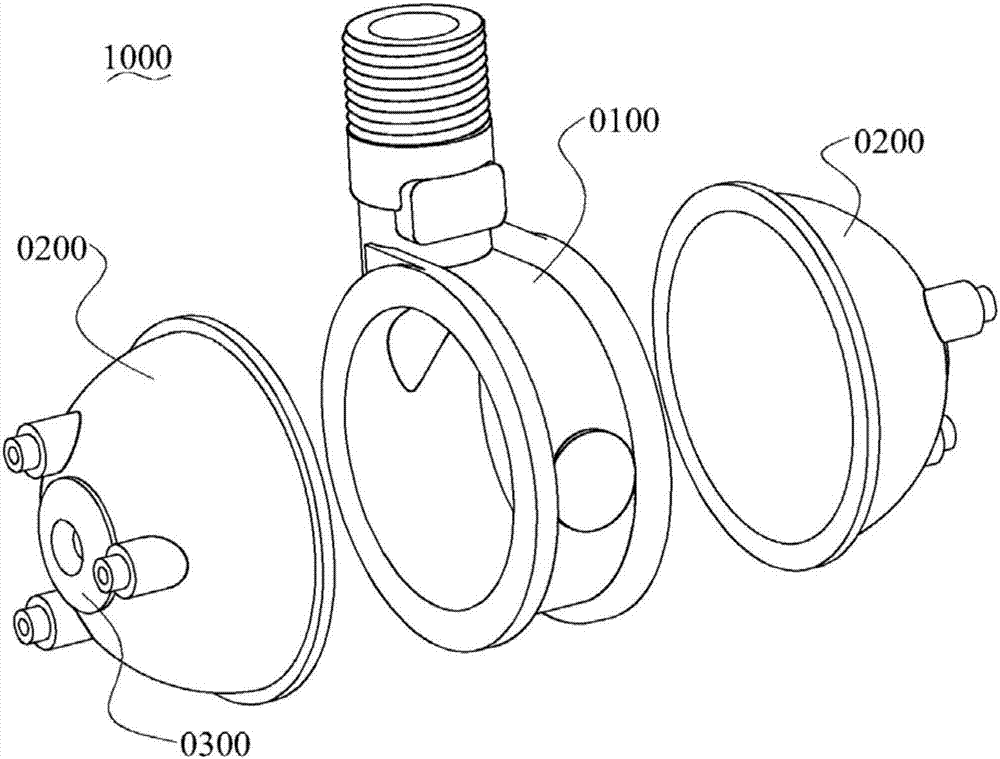

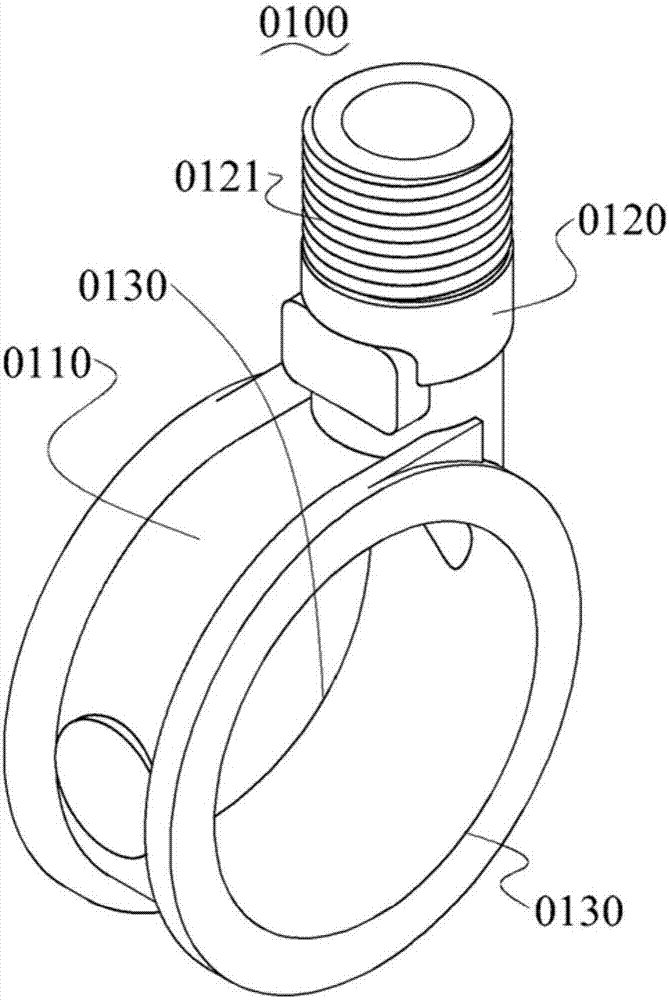

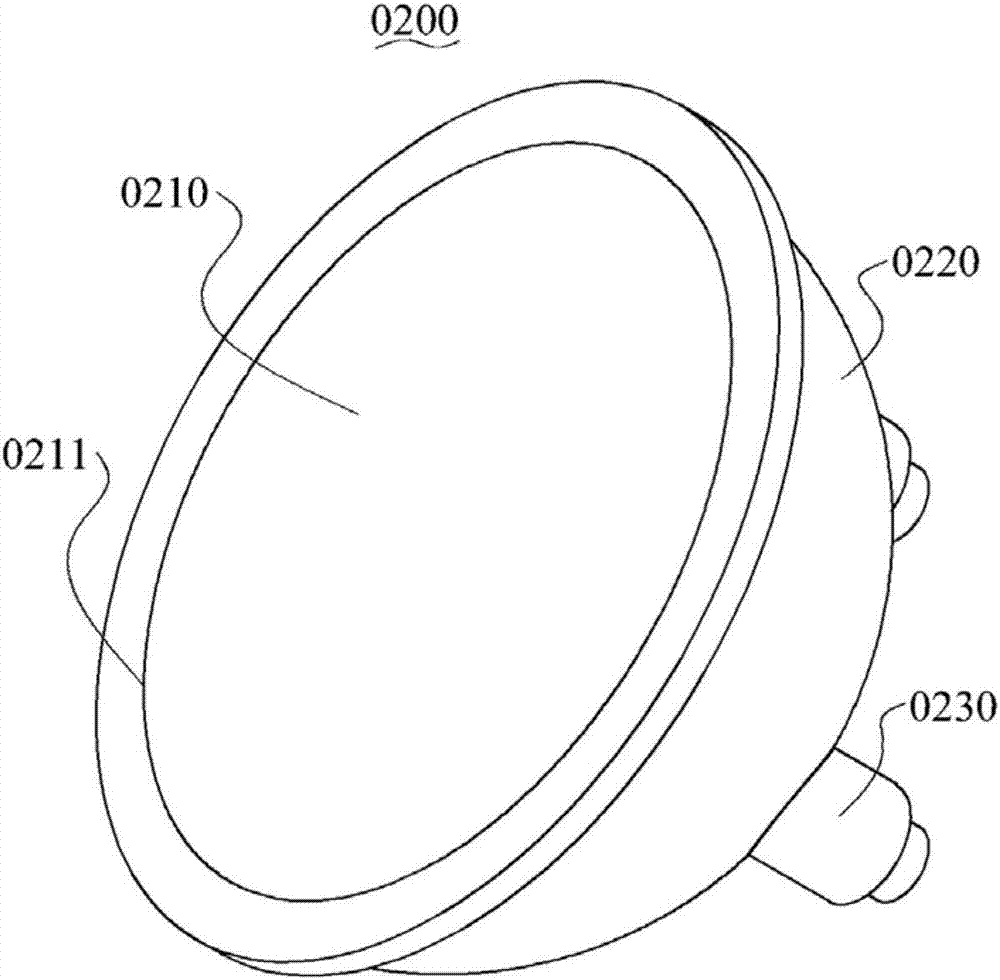

[0039] see Figure 1~2 The micro-nano-bubble spray head 1000 provided in this embodiment includes an injection chamber 0100 having an injection input port 0120 and an injection output port 0130. The injection chamber 0100 is used for high-speed swirling of the inflowing micro-nano-bubble liquid.

[0040] Preferably, the injection chamber 0100 includes a cylindrical cavity 0110, the cylindrical cavity 0110 has a through hole along its axial direction, the side wall of the through hole is provided with an injection input end 0120, and the openings at both ends of the through hole are injection output ends 0130 .

[0041] In an exemplary embodiment, the through hole forms an arc-shaped wall inside the cylindrical cavity 0110, the injection input end 0120 is arranged along a direction perpendicular to the axial direction of the cylindrical cavity 0110, and the injection output end 0130 is arranged along the cylindrical cavity Axial arrangement of body 0110.

[0042] Further pref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com