Power supply plug connection assembly

A technology of electric power supply and electric components, which is applied in the direction of electric components, parts of connecting devices, circuits, etc., can solve problems such as power outages of electrical facilities, electric shock accidents, unstable power supply connections, etc., and achieve increased use safety and simple operation Convenience and the effect of reducing electric shock accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

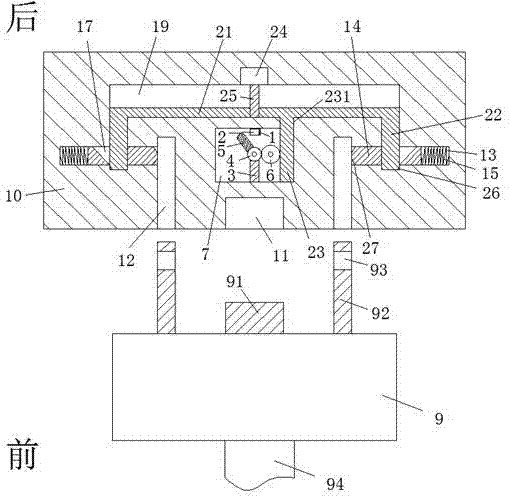

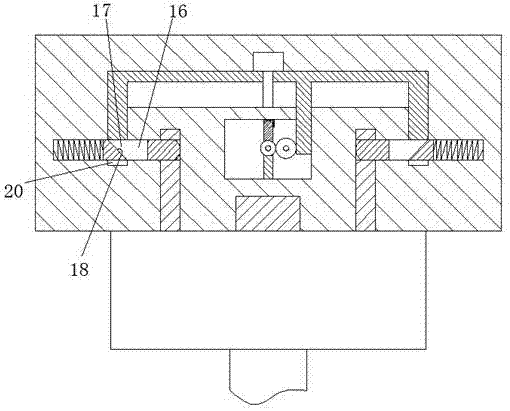

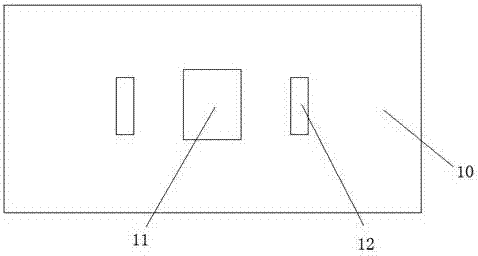

[0019] refer to Figure 1-3 The power supply plug-in assembly shown includes a power supply socket 10 embedded in the wall and a power connection part 9 for mating connection with the power supply socket 10. The middle of the rear end of the power connection part 9 is provided with The plug 91, the rear end of the power connection part 9 is respectively symmetrically provided with two plug boards 92 on the left and right sides of the plug 91, each of the plug boards 92 is provided with a locking groove 93 at the rear end, and the power supply socket A first power supply hole 11 is provided in the middle of the front end of the socket 10 to cooper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com