Pneumatic Tire

A technology of pneumatic tires and tires, which is applied in the direction of pneumatic tires, tire parts, tire edges, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

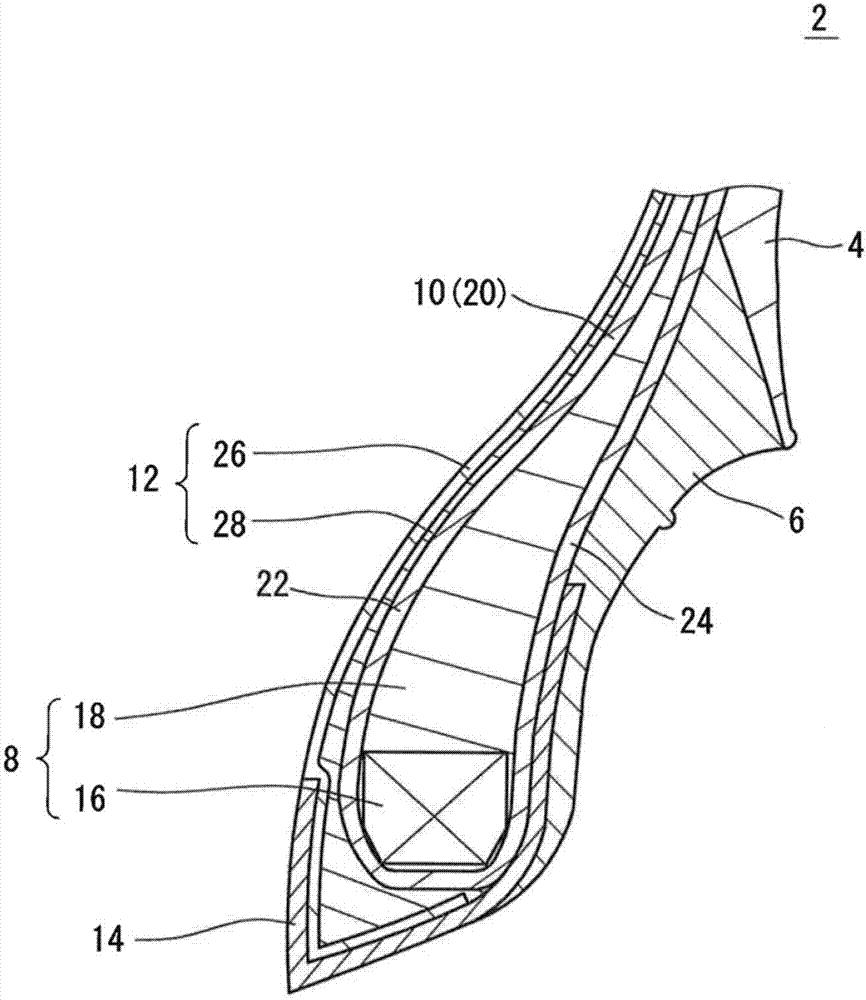

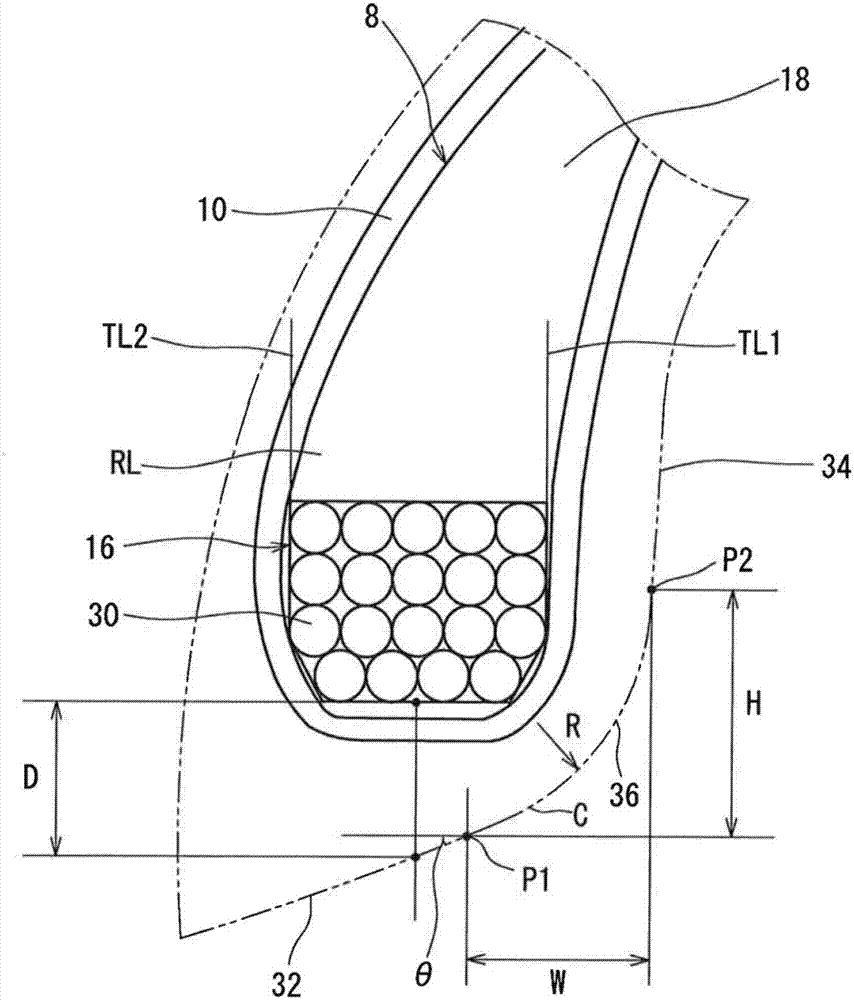

[0062] got equipped figure 1 The structure shown is the tire of Example 1 equipped with the specifications shown in Table 1 below. The size of this tire is 215 / 45R17. The structure of the tire core is as figure 2 like that. This is denoted by " figure 2 ” is shown. The axial width W of the arc C is 6.4 mm. The angle θ formed by the base of the core and the axial direction is 17°. For this tire, the distance D is 4.2 mm. The distance between the core and the base of the tire is 5% longer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com