Patents

Literature

44 results about "Heel surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

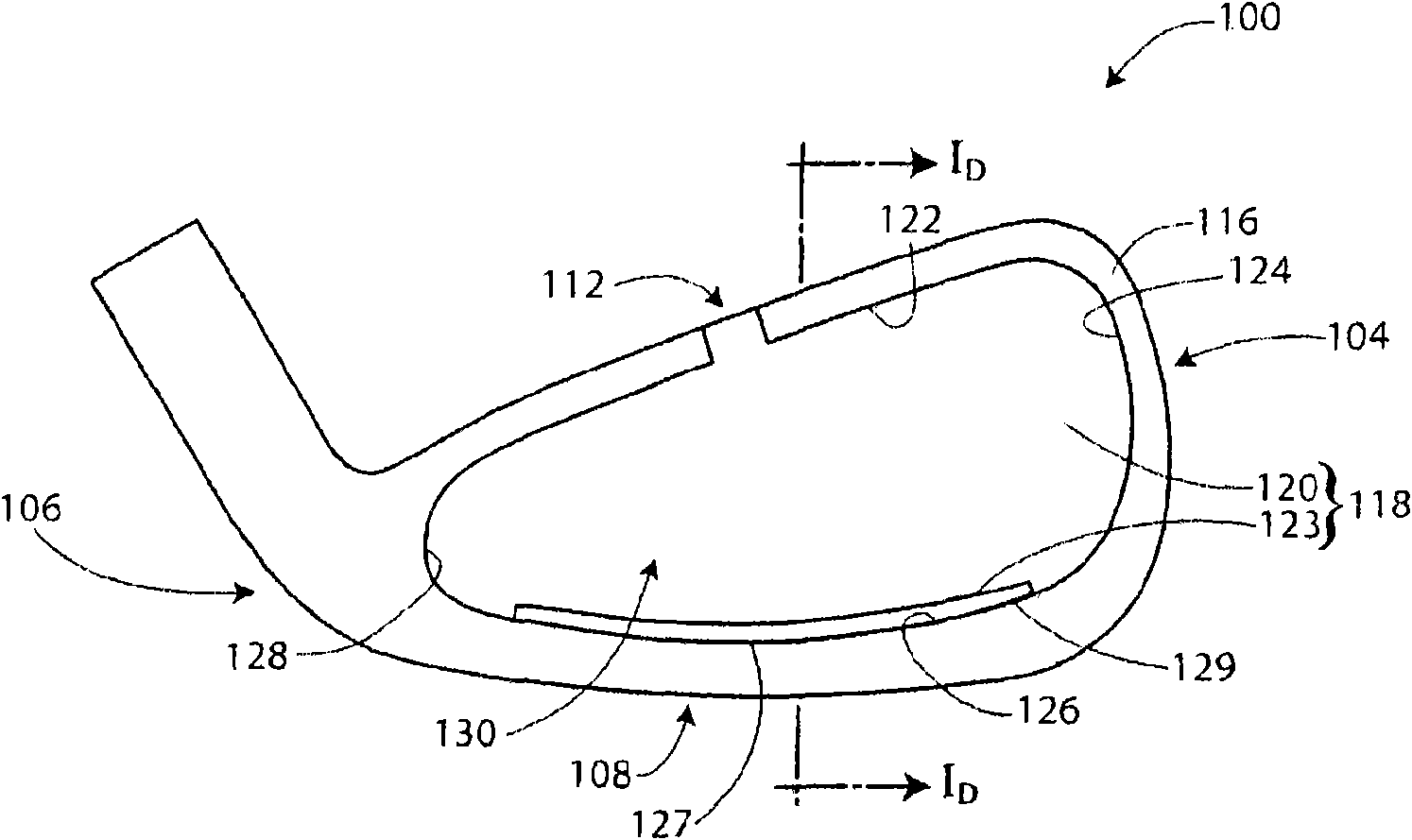

Muscle back, with insert, iron type golf club head

ActiveUS20080058120A1Improved feel and forgiveness characteristicGolf clubsRacket sportsGolf BallHeel surface

Owner:DUNLOP SPORTS CO LTD

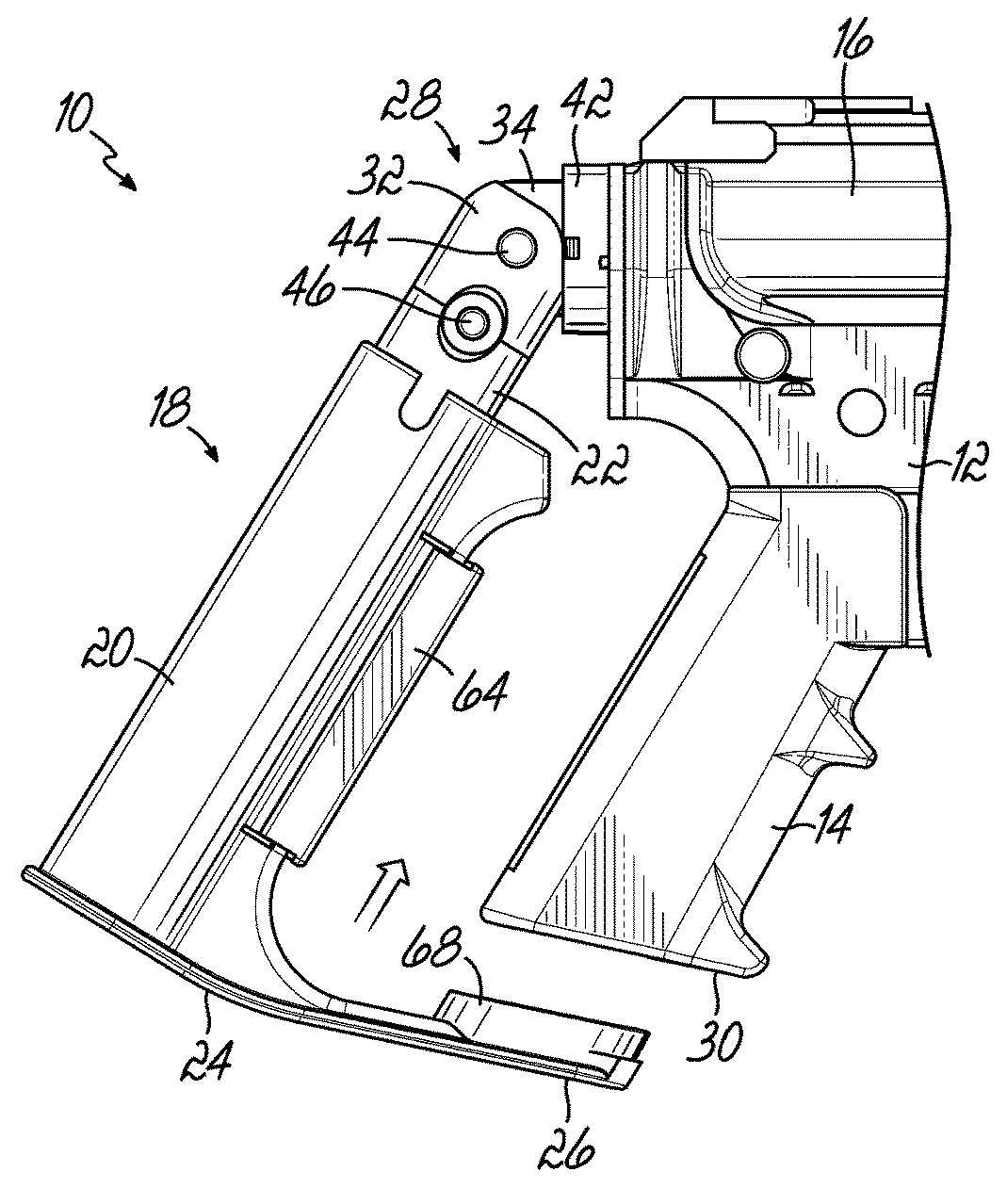

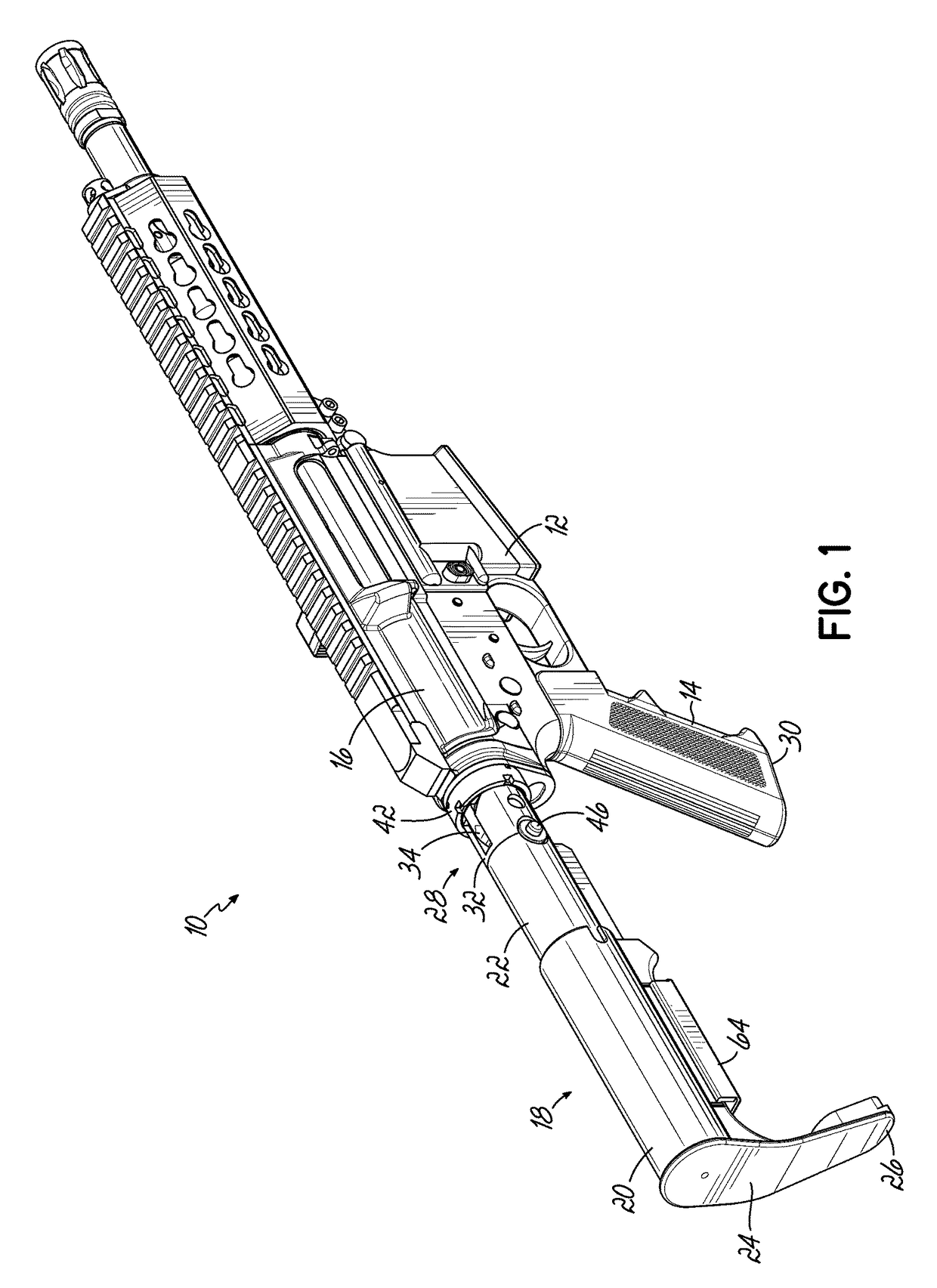

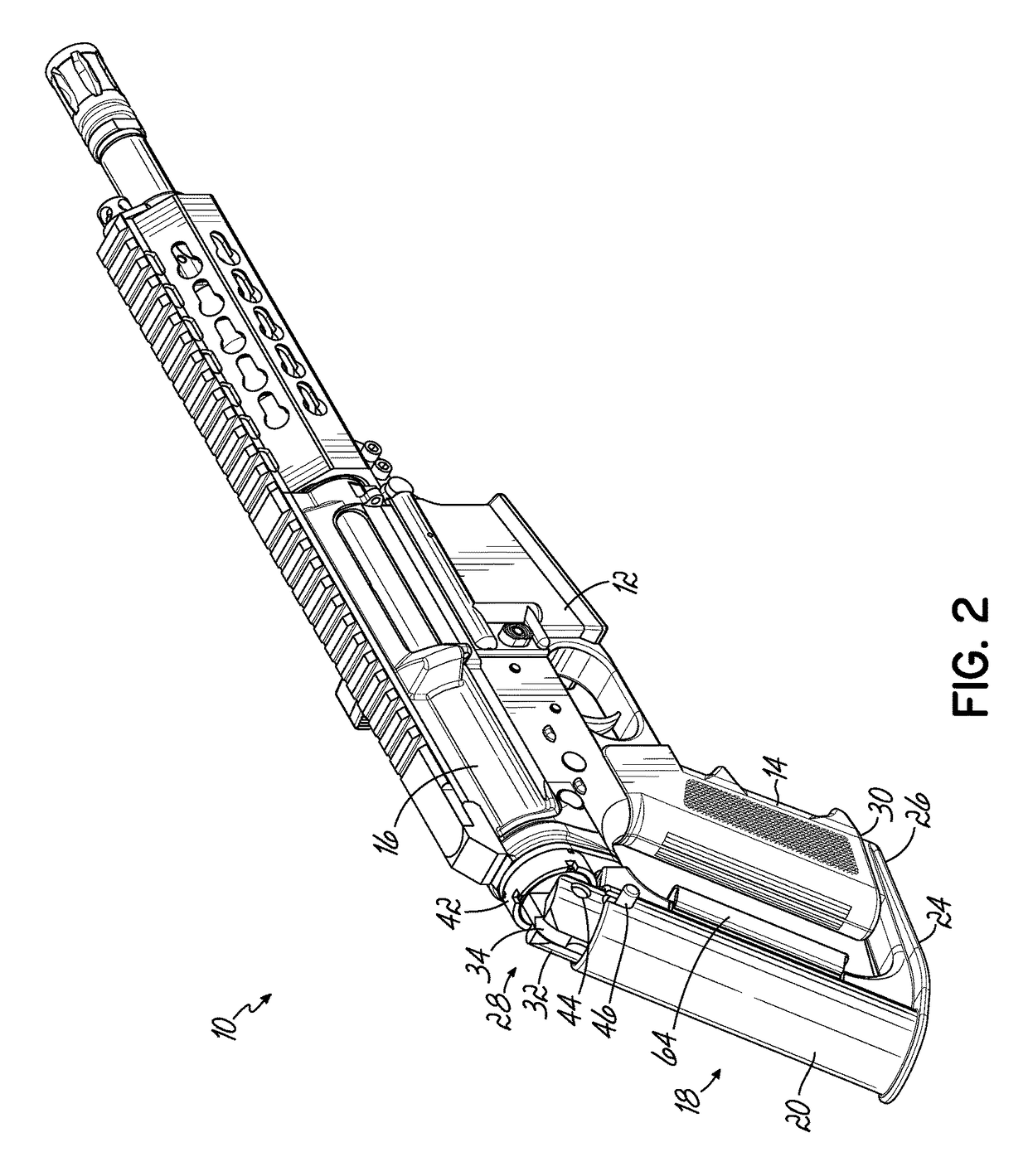

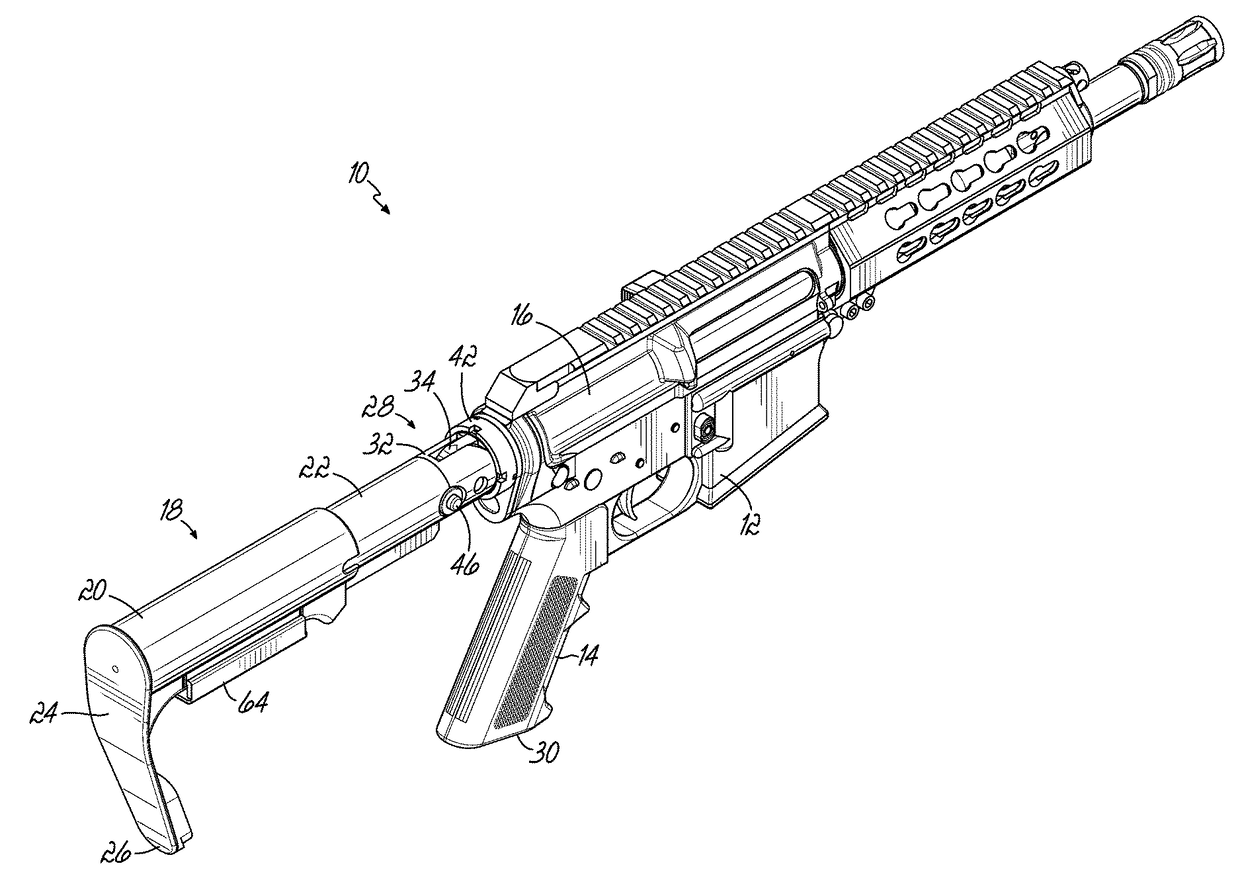

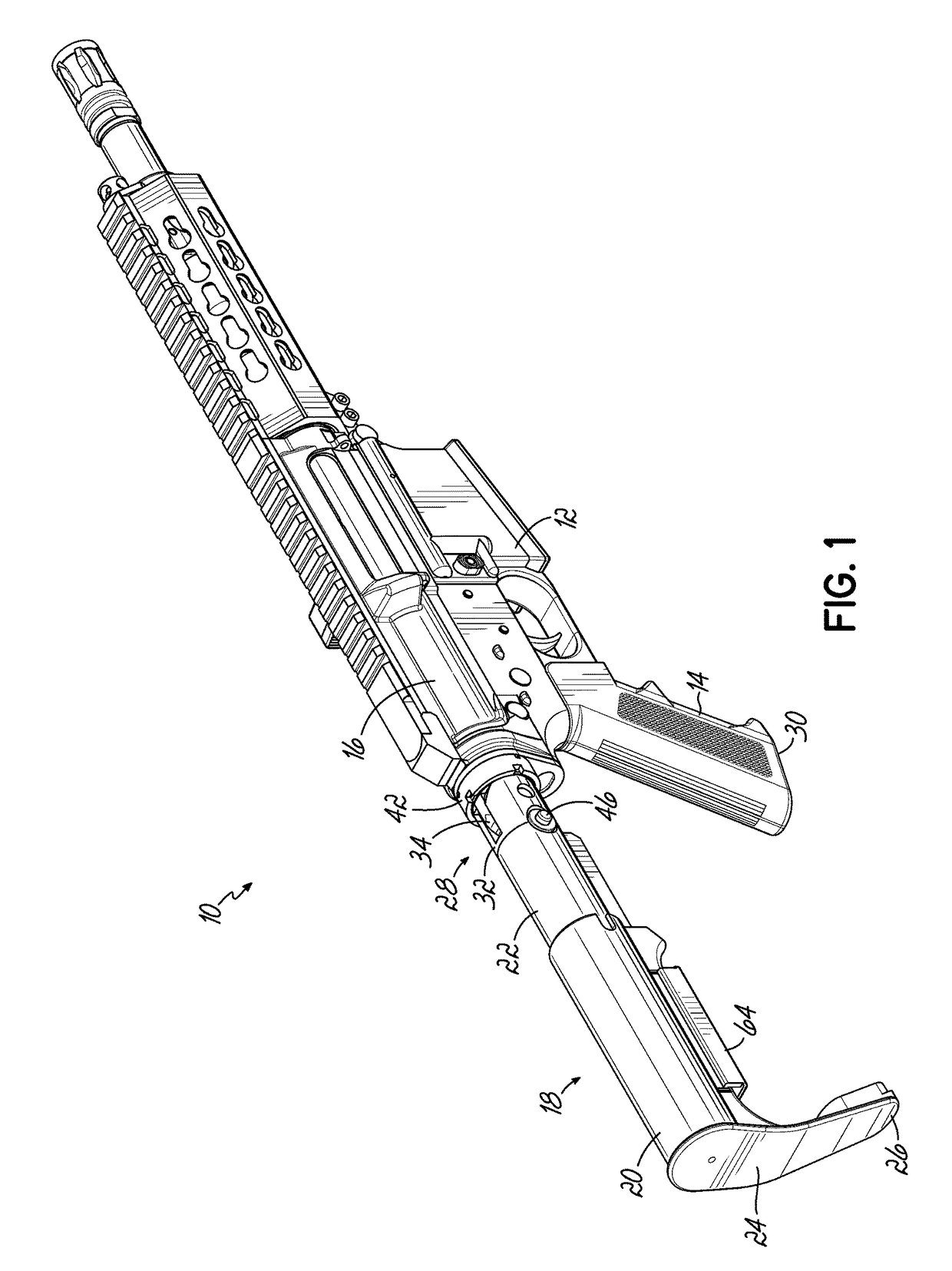

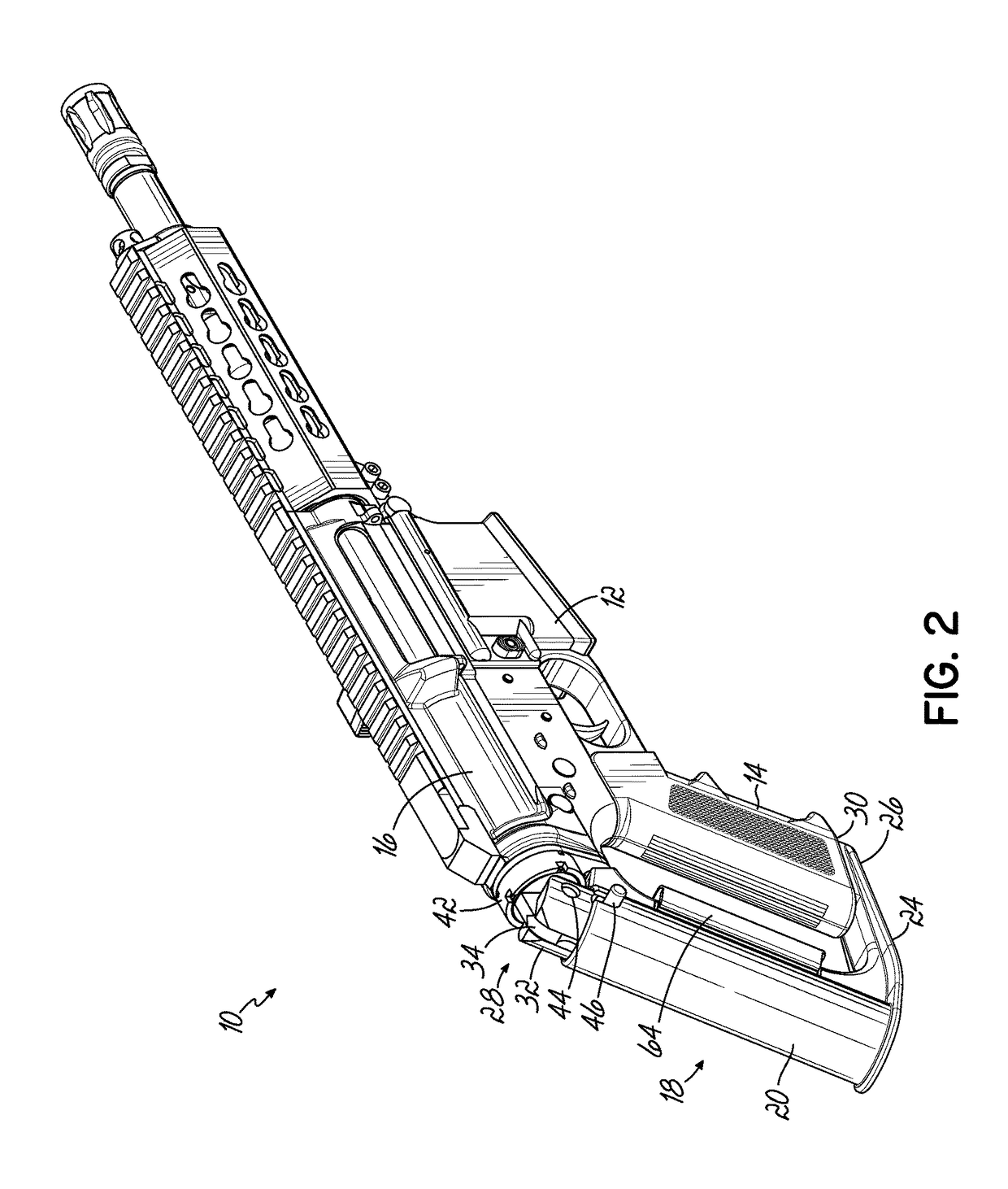

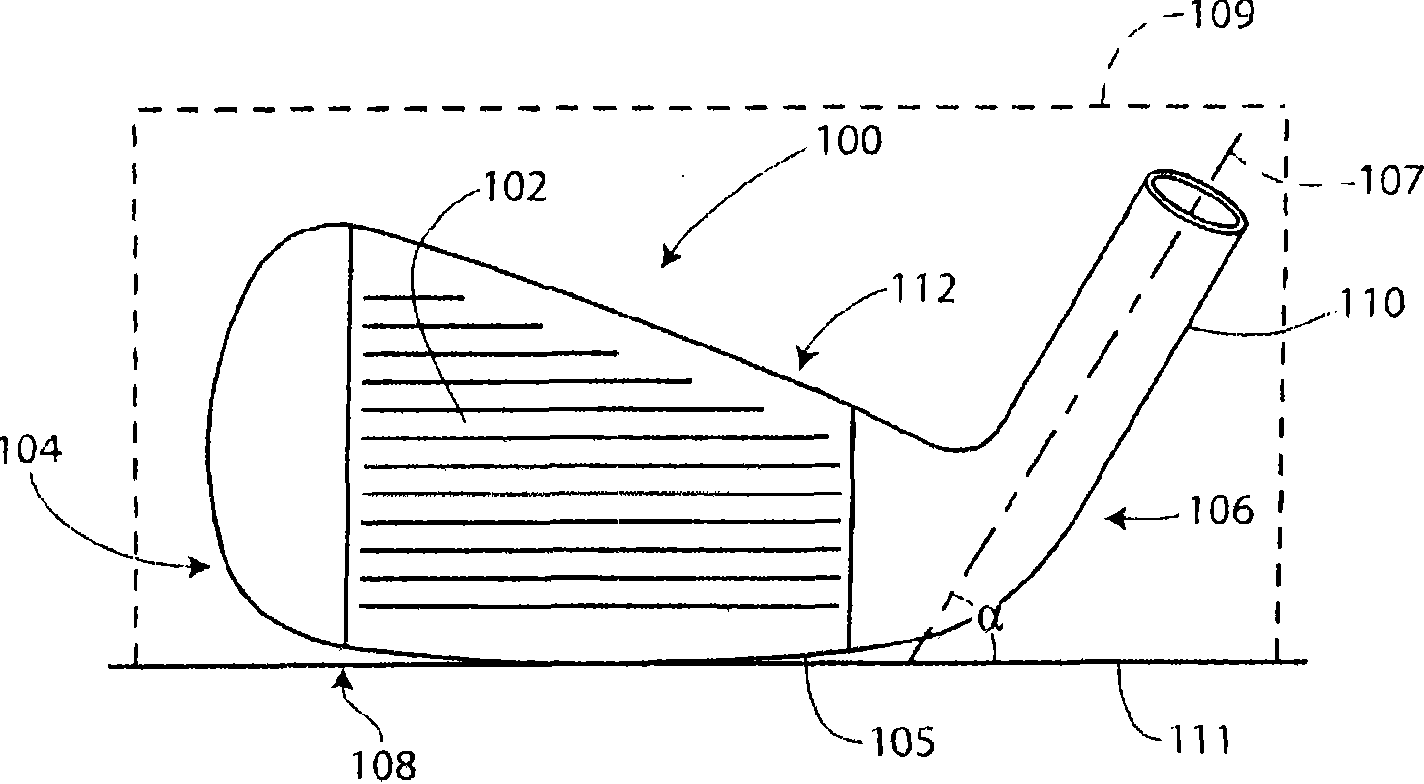

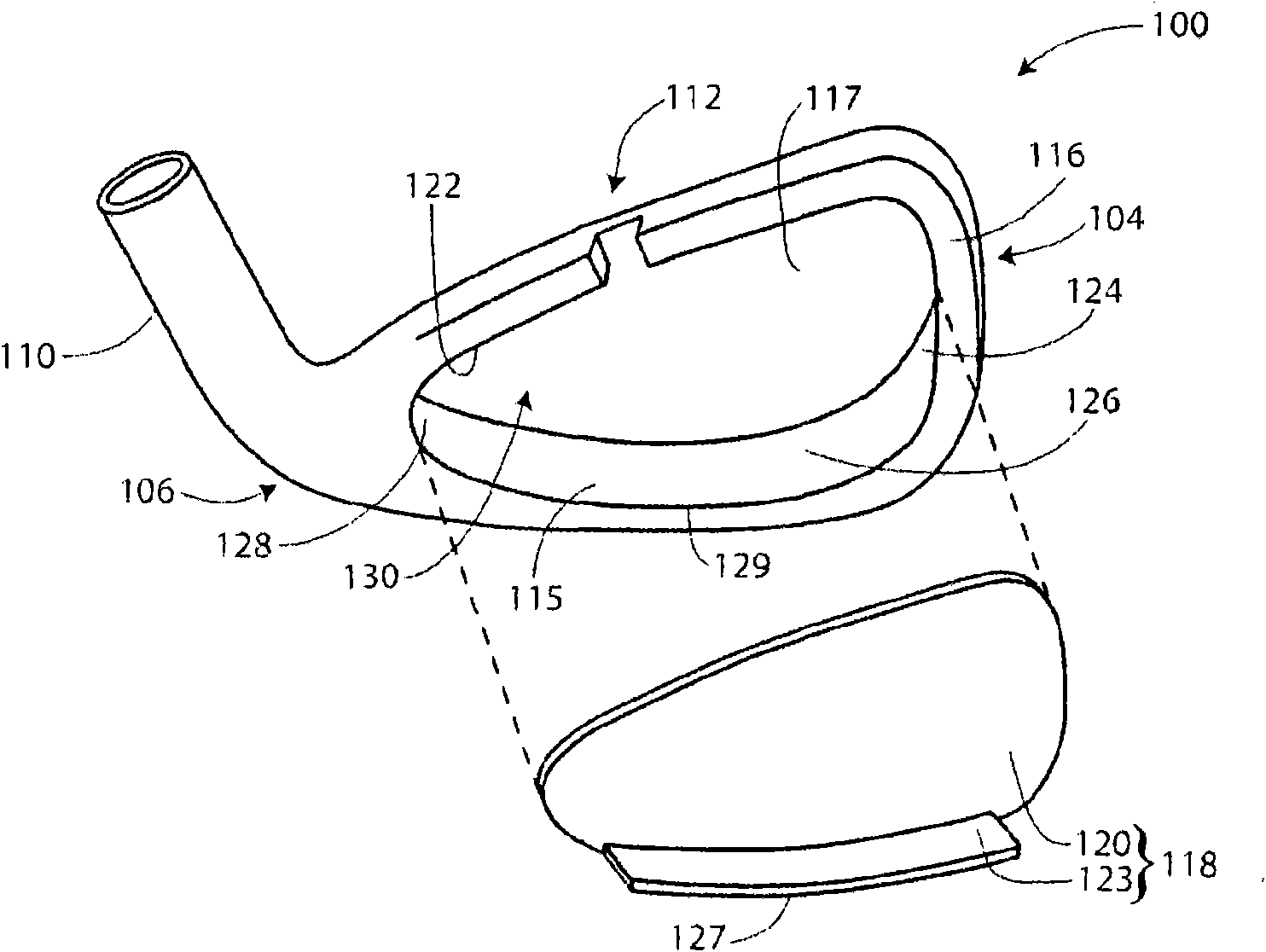

Foldable stock

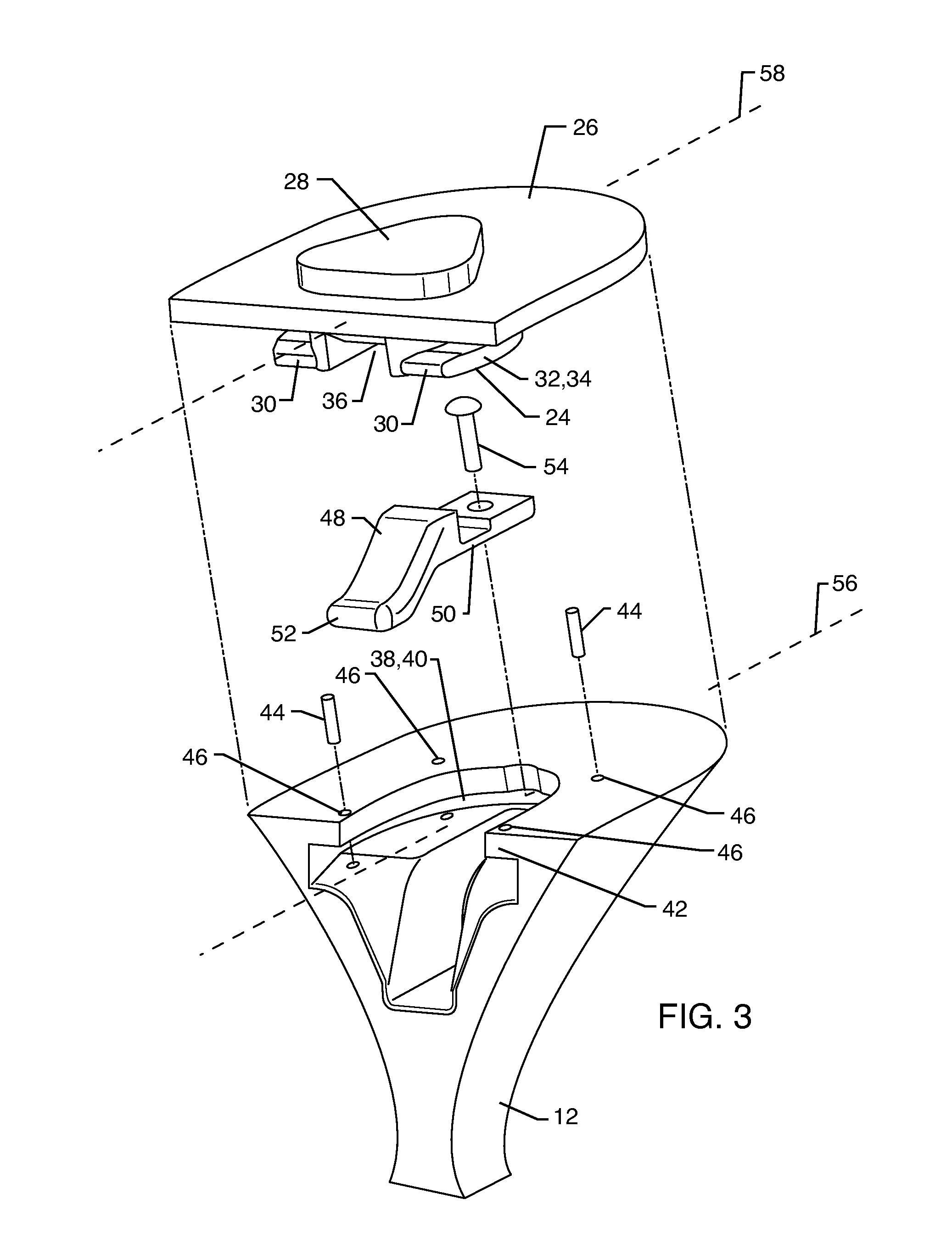

Disclosed is a foldable stock for a firearm having a separate pistol grip with an open end. The stock includes a knuckle having a first portion mountable to a firearm in a fixed position and a second portion pivotally attached to the first portion and movable about a substantially laterally transverse axis relative to the first portion between an unfolded position and a downwardly folded position. A support member longitudinally extends from the second portion and a butt member is carried on the support member. The butt member is selectively longitudinally positionable on the support member relative to the knuckle between at least an extended position and a collapsed position. The butt member includes a heel surface for abutting a user's shoulder with a downwardly extending toe portion. The toe portion includes a connector configured to connectably engage the open end of the pistol grip and prevent pivotal movement of the knuckle when in the downwardly folded position with the butt member in the collapsed position. The knuckle is movable toward the unfolded position when the butt member is at least partially extended on the support member away from the collapsed position to disengage the connector from the open end of the pistol grip.

Owner:AMBIMJB

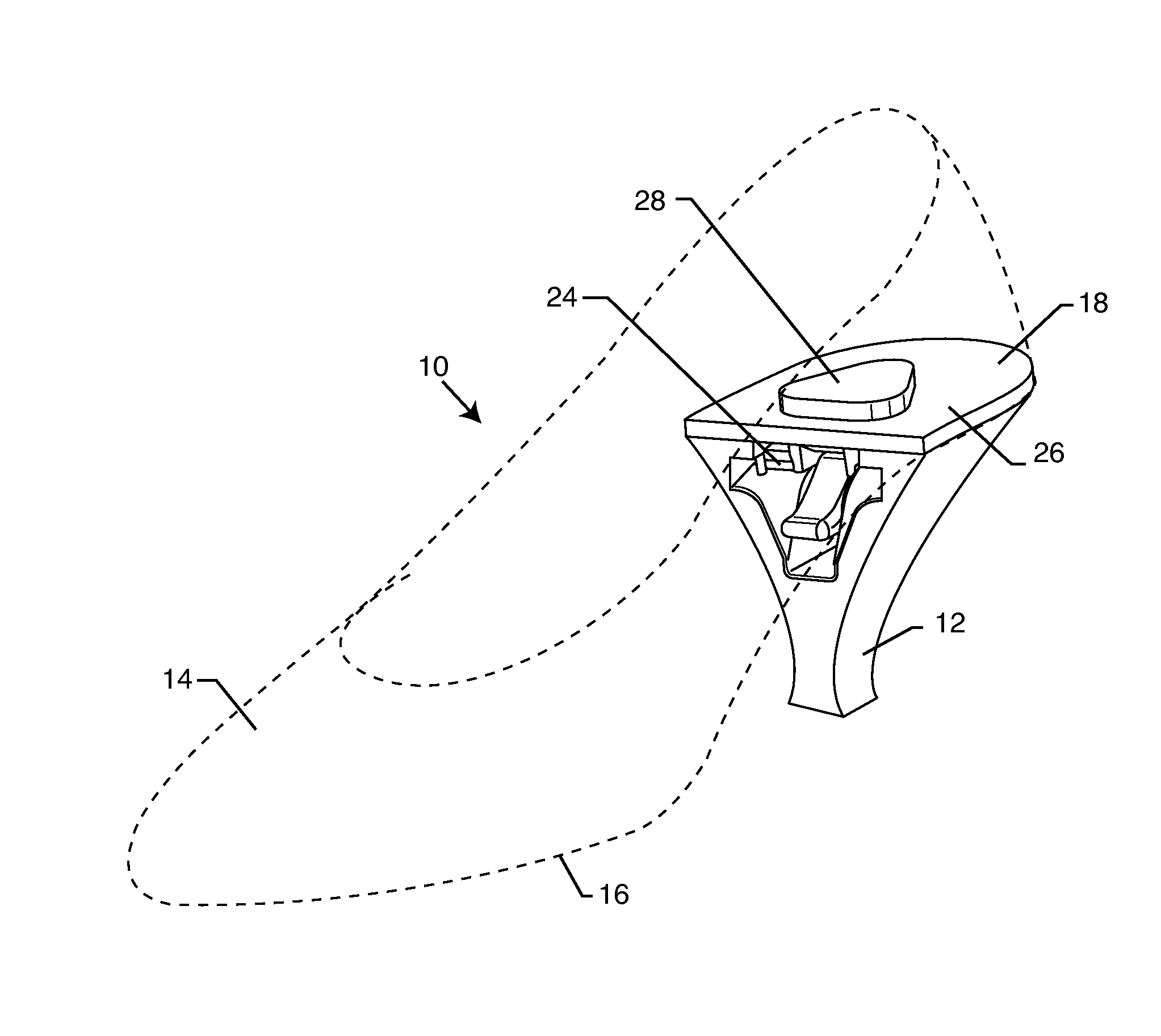

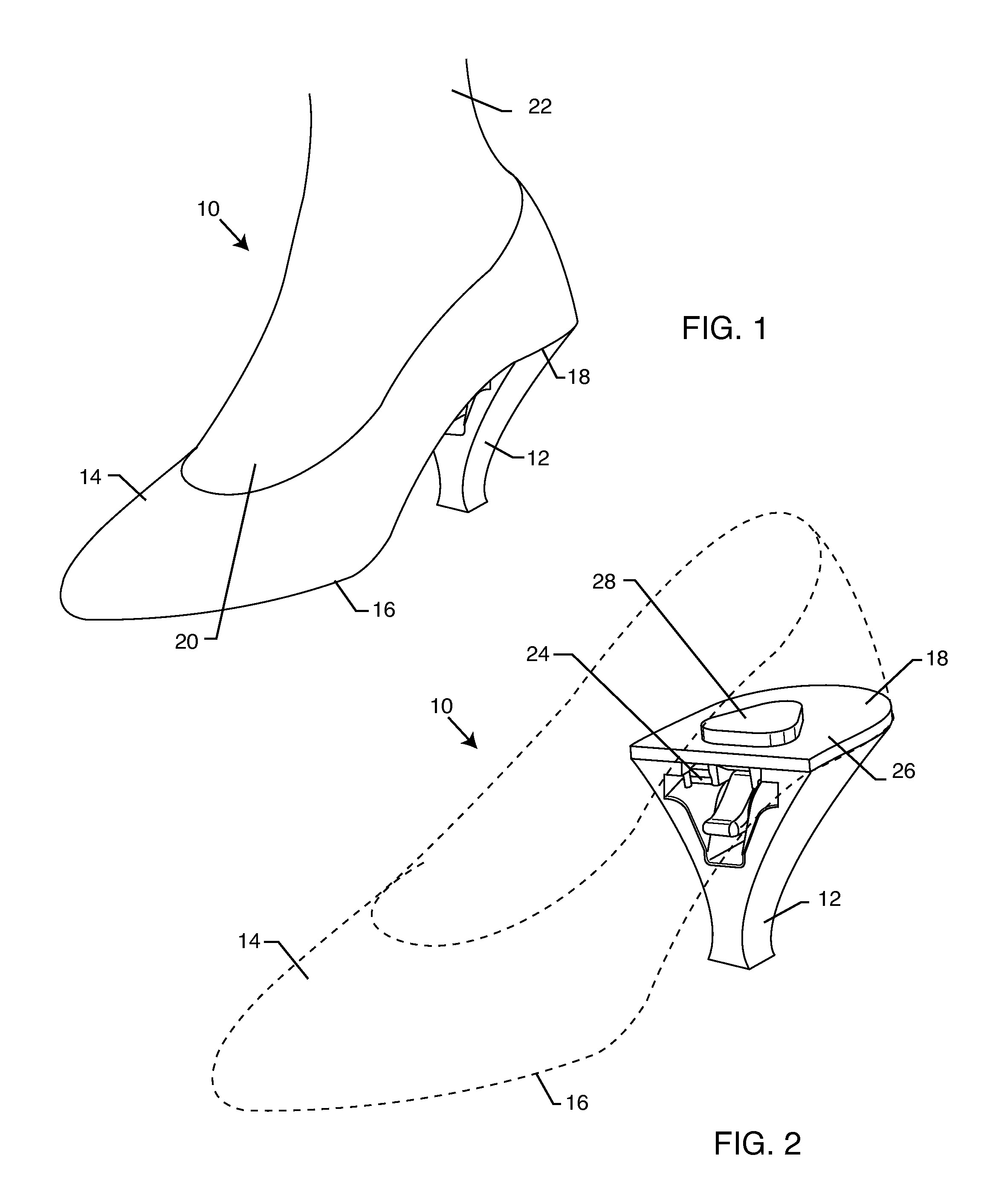

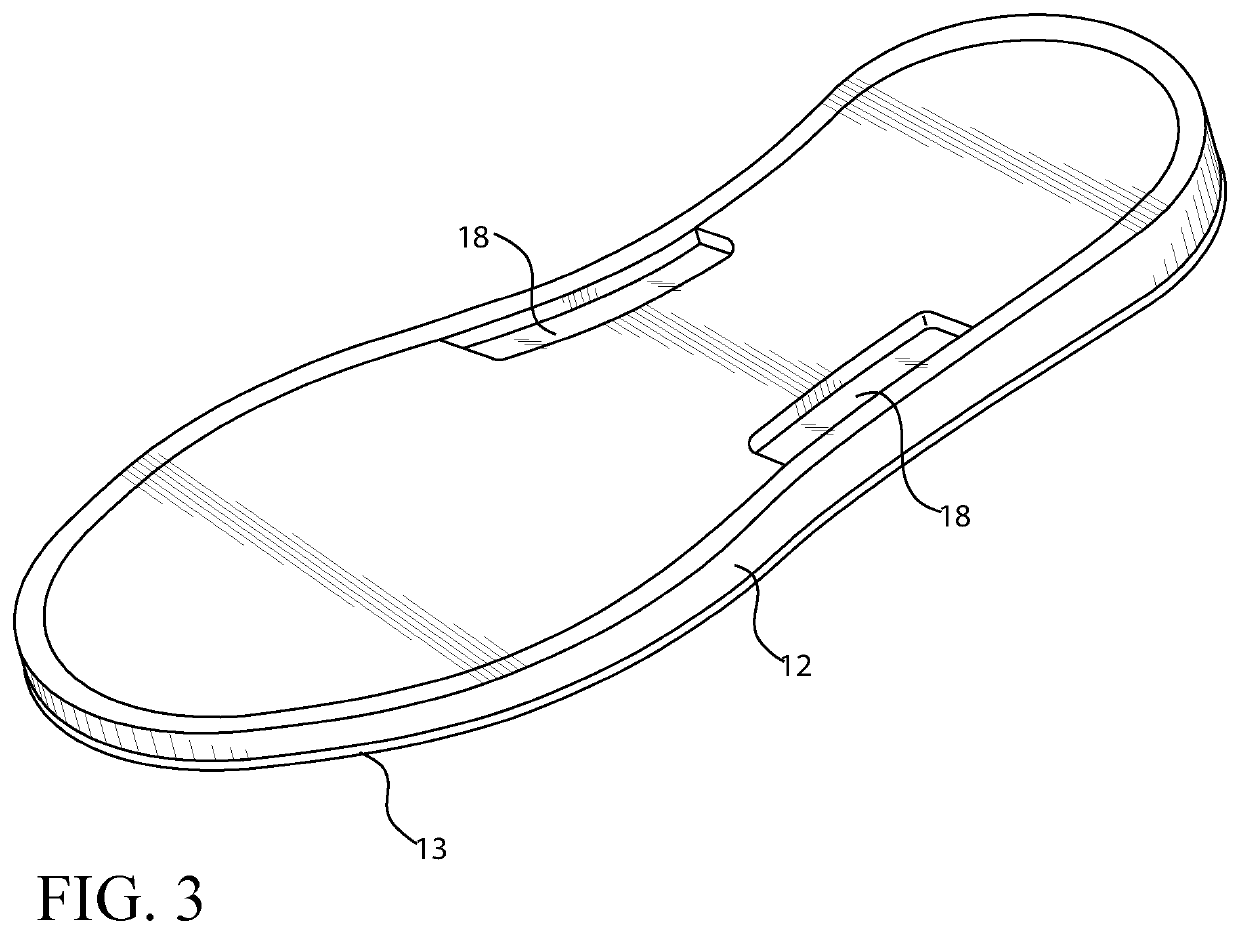

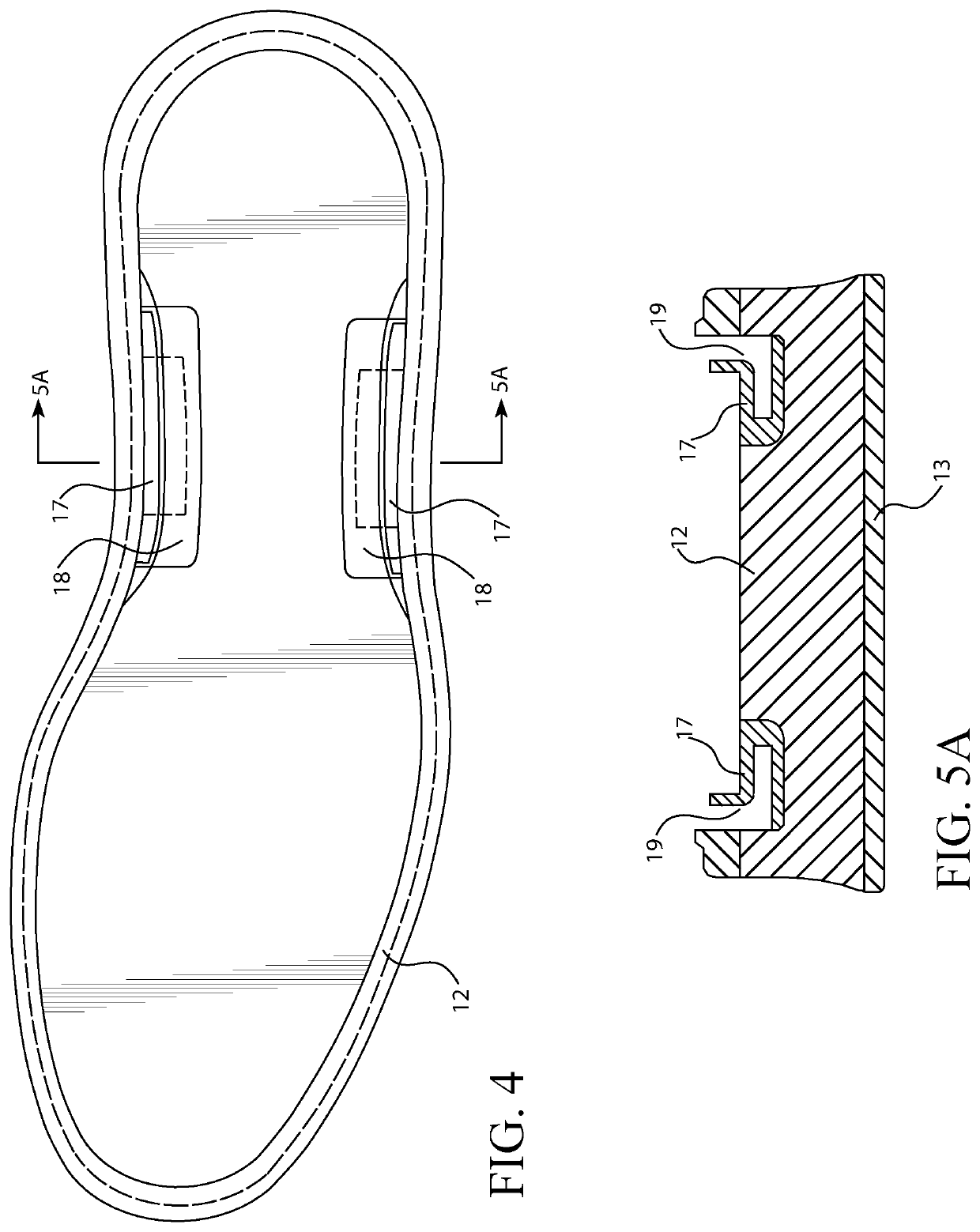

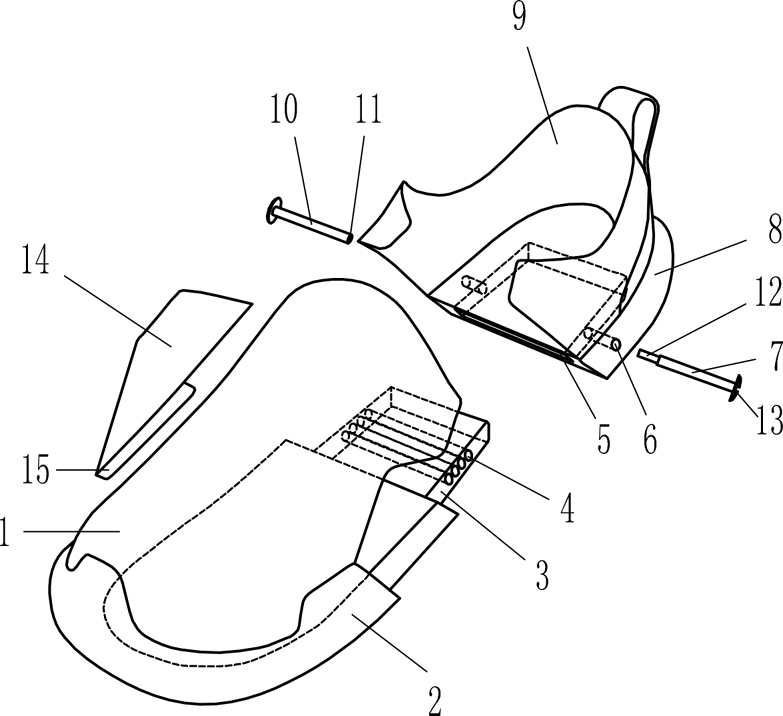

Shoe with interchangeable heels

InactiveUS20130067770A1Inhibition of translationPrevent rotationHeelsTop-piecesEngineeringHeel surface

A shoe includes an interchangeable heel having a shoe body configured to accept a foot of a person. A protrusion is permanently attached to a bottom heel surface comprising two oppositely disposed straight edges separating and contiguous with two oppositely disposed curved edges. A channel is disposed within the protrusion between the two oppositely disposed curved edges. A removable heel comprises an open-ended slot configured to securely accept the protrusion. The removable heel is rotatably attachable to the protrusion. The at least one stop is attached to the removable heel and configured to prevent translation of the removable heel relative to the protrusion. A flexural lock attached to the removable heel is configured to engage the channel and prevent rotation of the removable heel relative to the protrusion. The flexural lock may be manually disengaged by the person to release the removable heel from the protrusion.

Owner:SHERWOOD JULIANA LUTZI +1

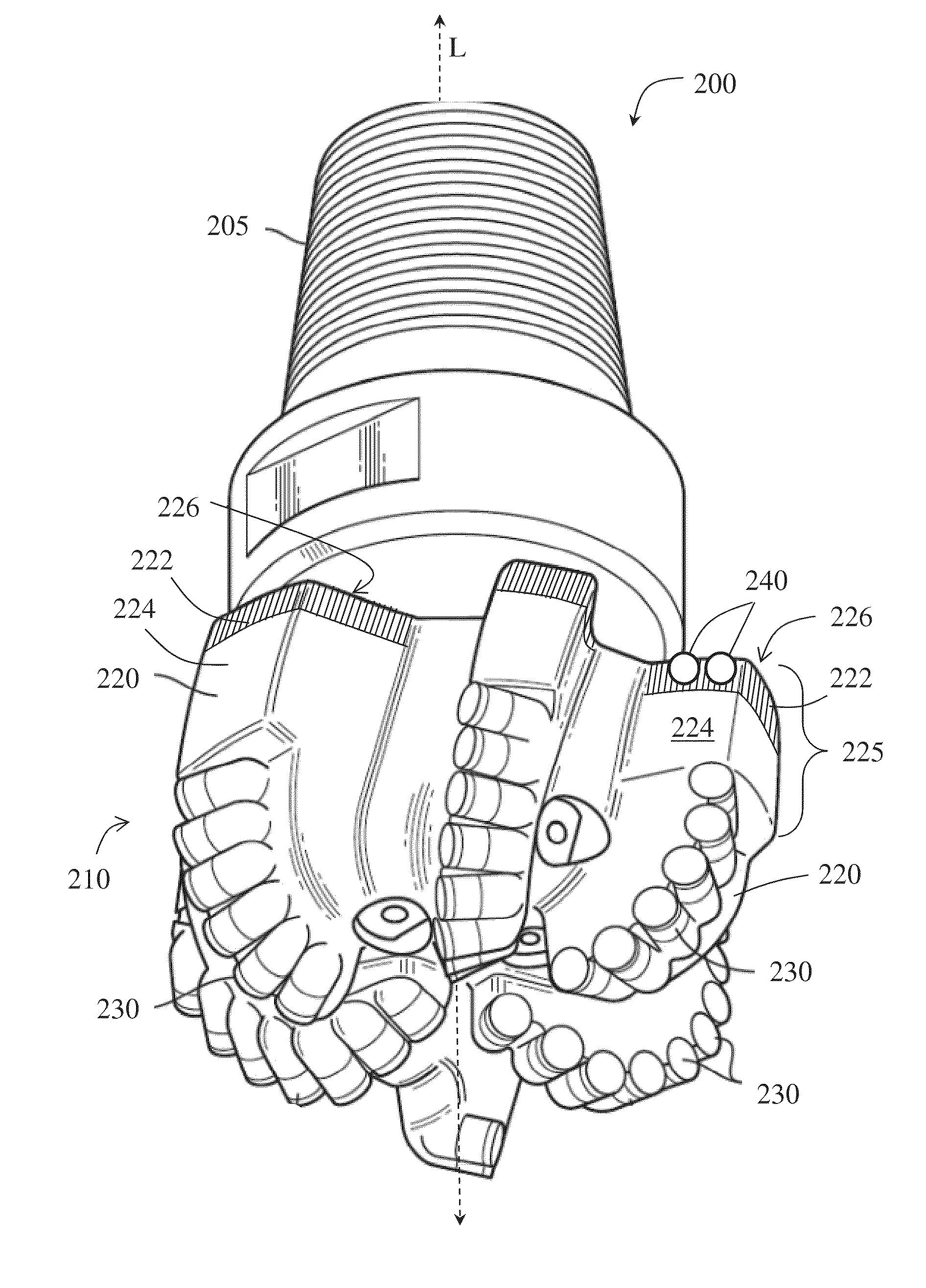

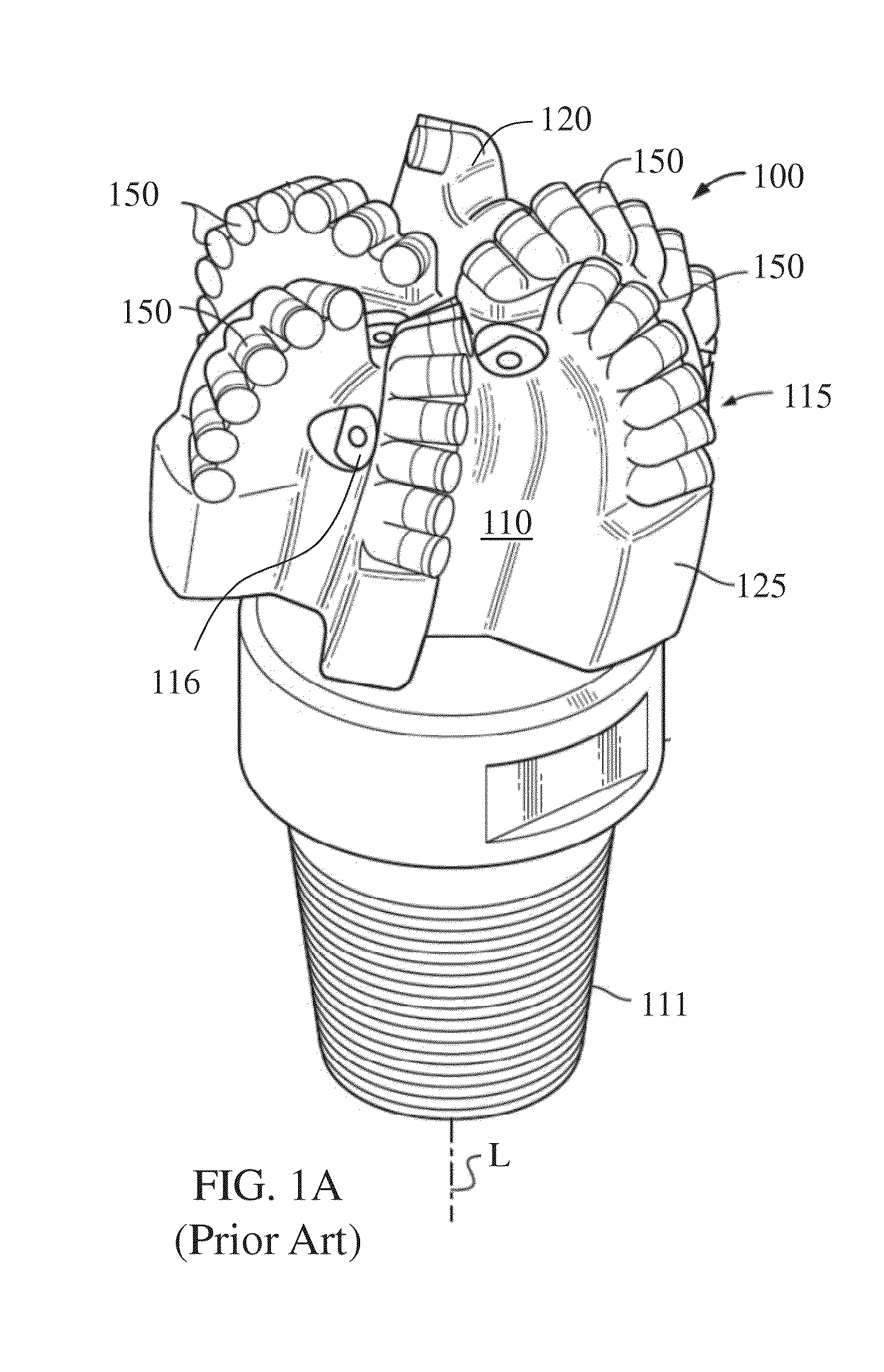

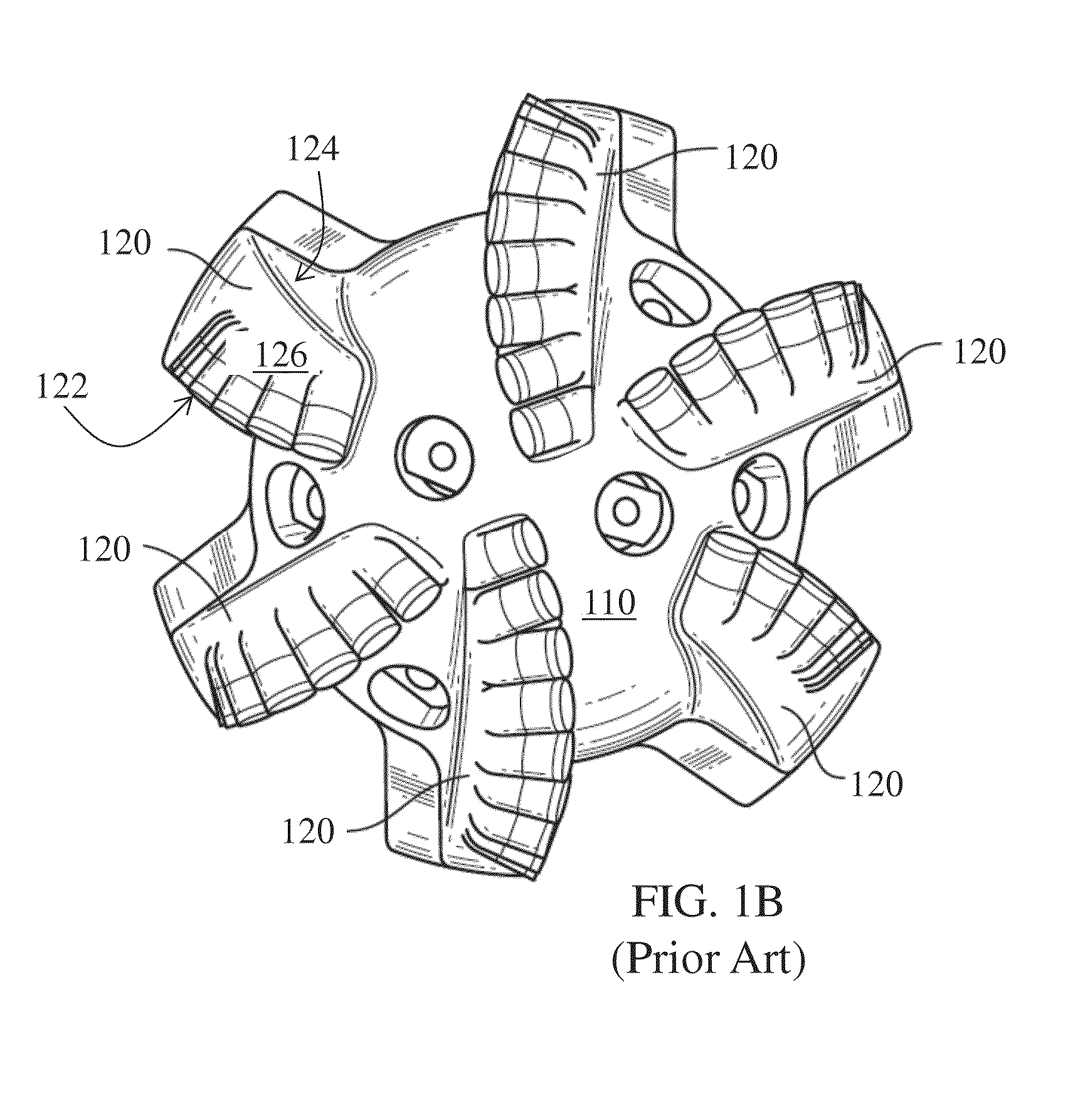

Fixed cutter drill bit heel and back-ream cutter protections for abrasive applications

A method of manufacturing a fixed cutter drill bit may include loading a first matrix material of controlled thickness to at least a portion of a mold cavity corresponding to a heel surface of at least one blade; loading a second matrix material into the remaining portions of the mold cavity; heating the mold contents to form a matrix body of the fixed cutter drill bit; and disposing at least one back reaming element in at least one back reaming cutter pocket.

Owner:SMITH INT INC

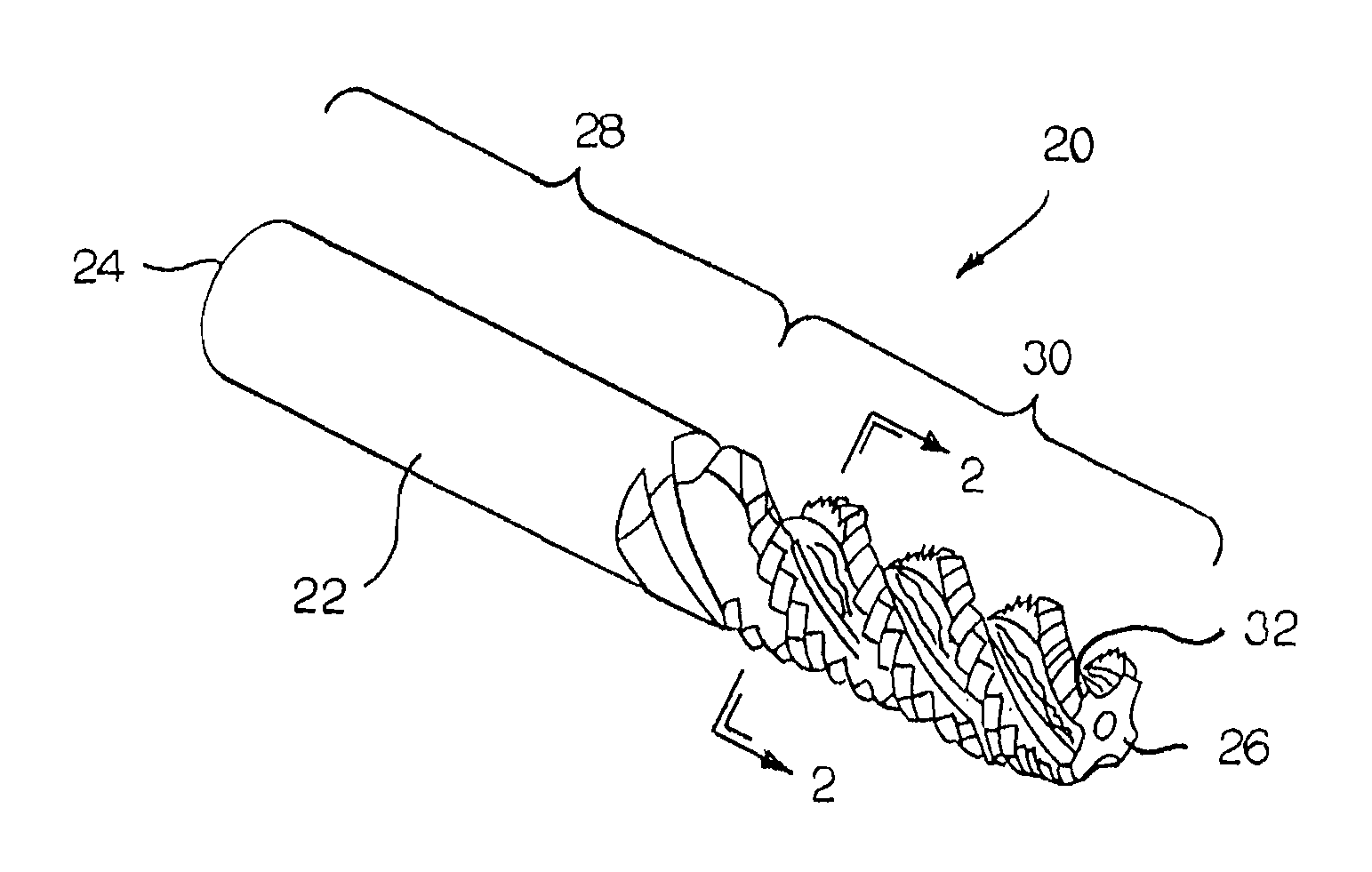

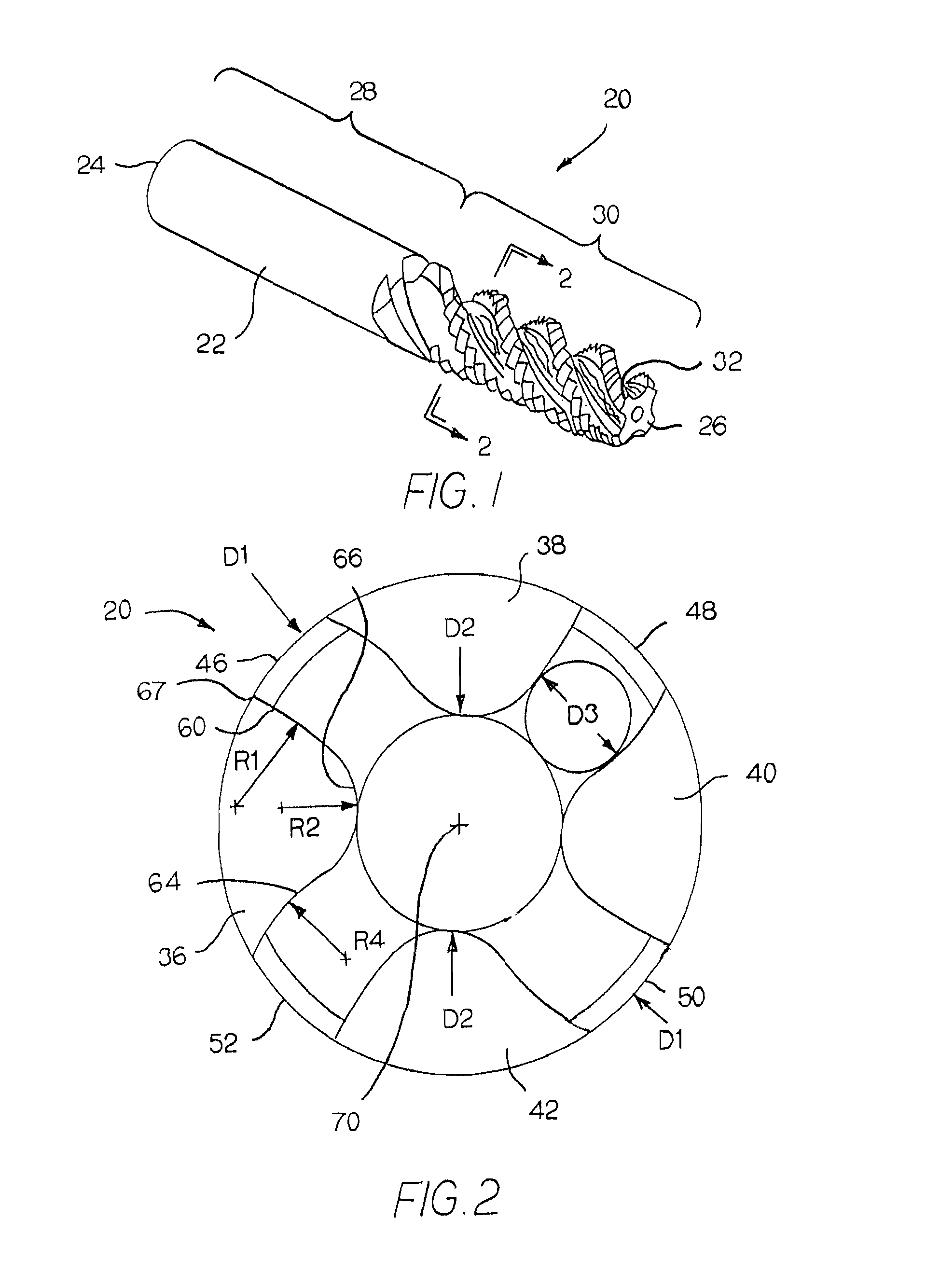

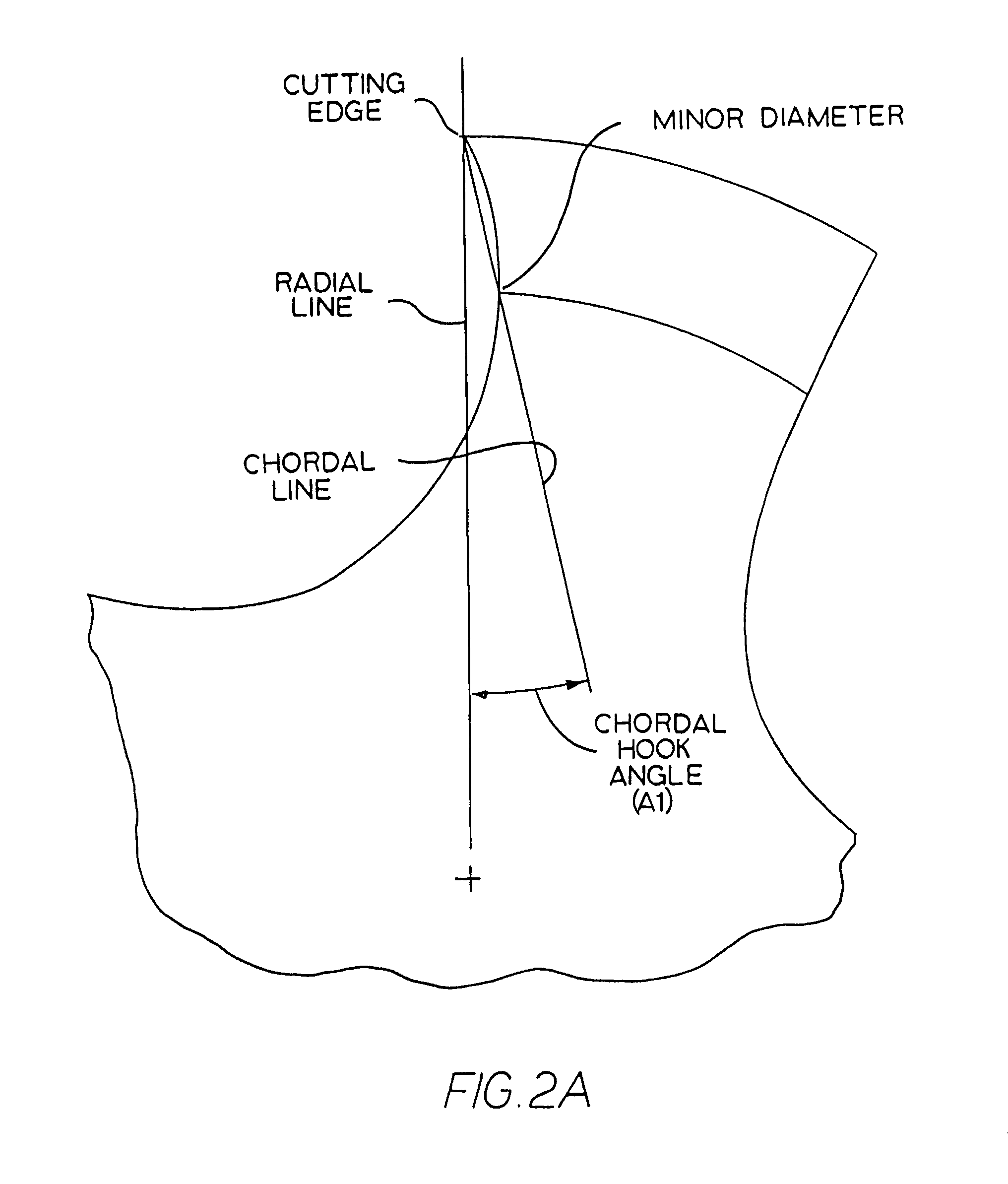

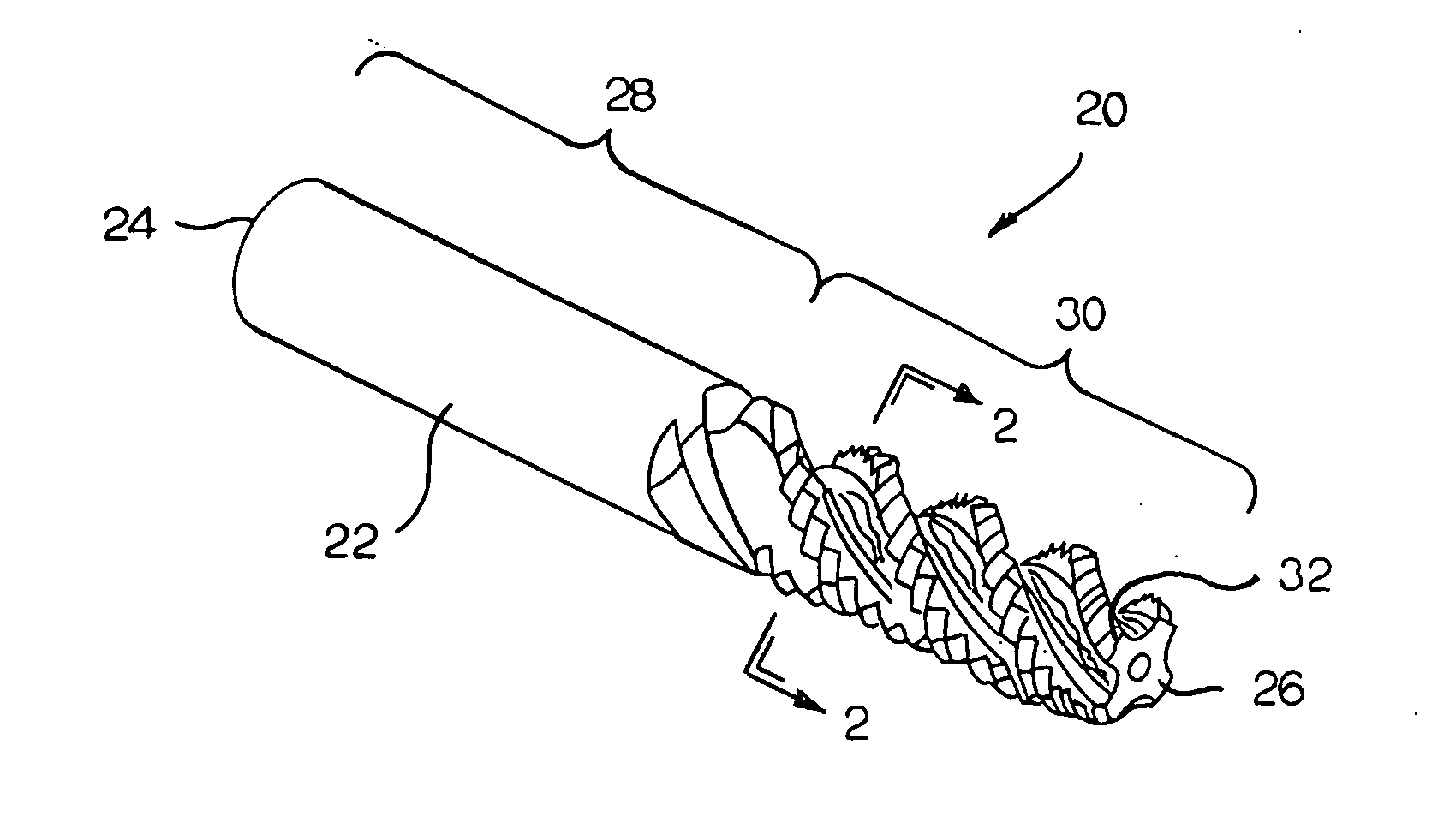

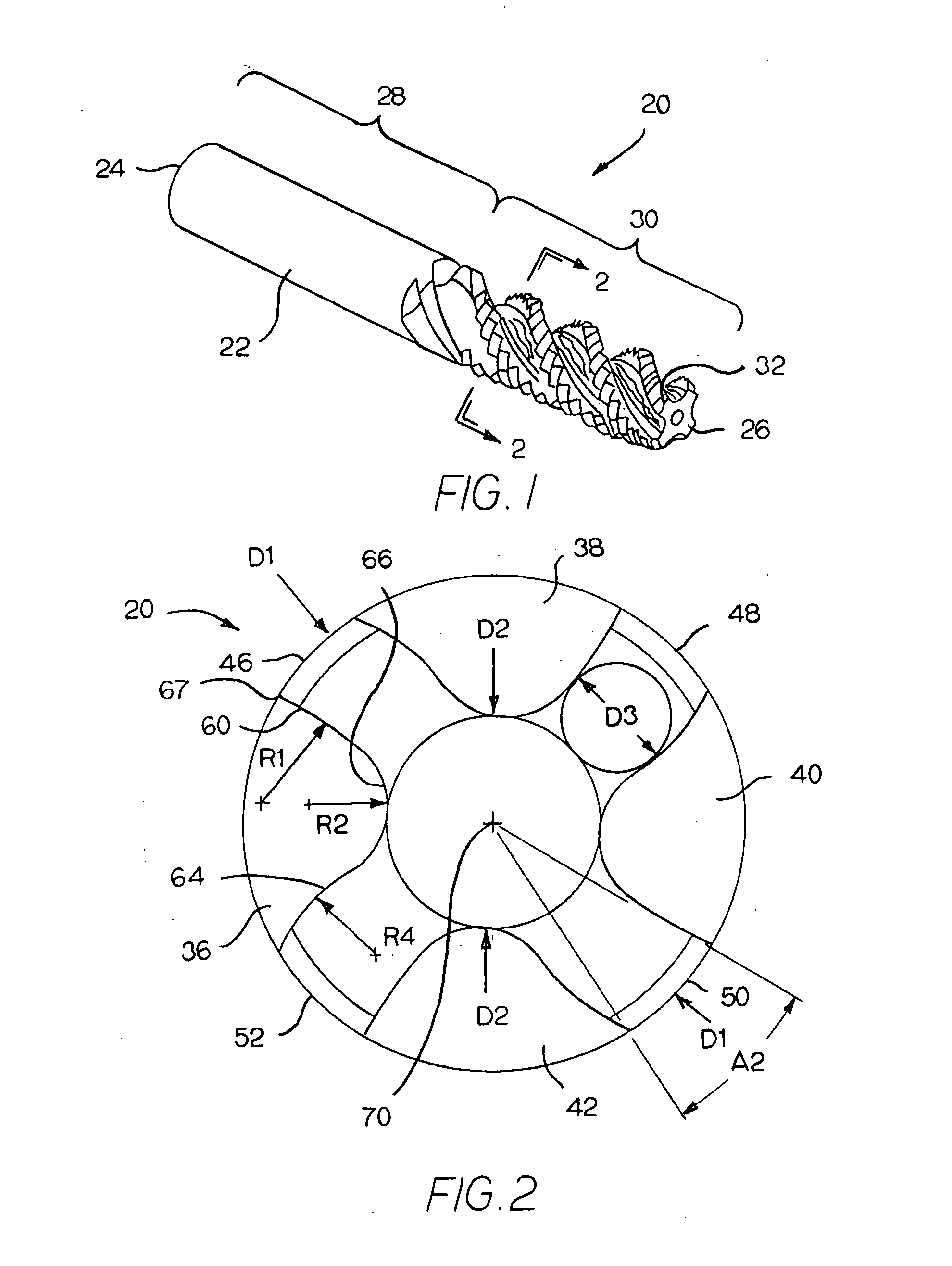

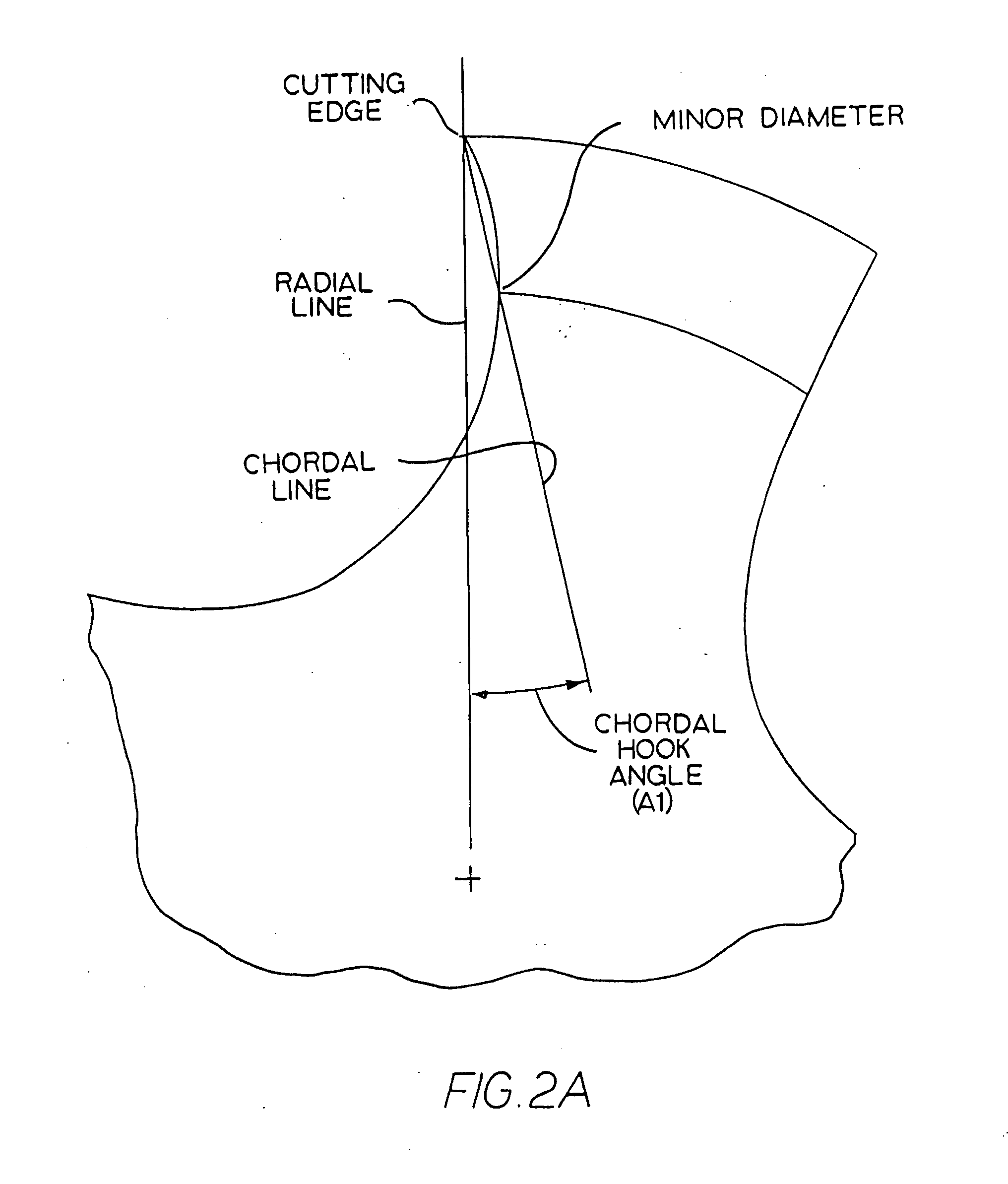

Spiral flute tap

ActiveUS7950880B2Improve wear resistanceReduce intensityThread cutting toolsWood turning toolsEngineeringFront and back ends

A cutting tool that includes an elongate body that has a forward end and a rearward end. The elongate body has a fluted portion that beginning near and extends in a rearward direction from the forward end. The fluted portion has a flute that defines a cutting edge. The flute presents a concave cutting face wherein the concave cutting face is defined by a first radius. The flute further presents a concave core surface adjacent to the concave cutting face wherein the concave core surface is defined by a second radius. The flute presents a convex heel surface adjacent to the concave core surface wherein the convex heel surface is defined by a fourth radius.

Owner:KENNAMETAL INC +1

Spiral flute tap

ActiveUS20080095588A1Improve wear resistanceReduce intensityThread cutting toolsWood turning toolsFluteEngineering

A cutting tool that includes an elongate body that has a forward end and a rearward end. The elongate body has a fluted portion that beginning near and extends in a rearward direction from the forward end. The fluted portion has a flute that defines a cutting edge. The flute presents a concave cutting face wherein the concave cutting face is defined by a first radius. The flute further presents a concave core surface adjacent to the concave cutting face wherein the concave core surface is defined by a second radius. The flute presents a convex heel surface adjacent to the concave core surface wherein the convex heel surface is defined by a fourth radius.

Owner:KENNAMETAL INC +1

Foldable stock

Disclosed is a foldable stock for a firearm having a separate pistol grip with an open end. The stock includes a knuckle having a first portion mountable to a firearm in a fixed position and a second portion pivotally attached to the first portion and movable about a substantially laterally transverse axis relative to the first portion between an unfolded position and a downwardly folded position. A support member longitudinally extends from the second portion and a butt member is carried on the support member. The butt member is selectively longitudinally positionable on the support member relative to the knuckle between at least an extended position and a collapsed position. The butt member includes a heel surface for abutting a user's shoulder with a downwardly extending toe portion. The toe portion includes a connector configured to connectably engage the open end of the pistol grip and prevent pivotal movement of the knuckle when in the downwardly folded position with the butt member in the collapsed position. The knuckle is movable toward the unfolded position when the butt member is at least partially extended on the support member away from the collapsed position to disengage the connector from the open end of the pistol grip.

Owner:AMBIMJB

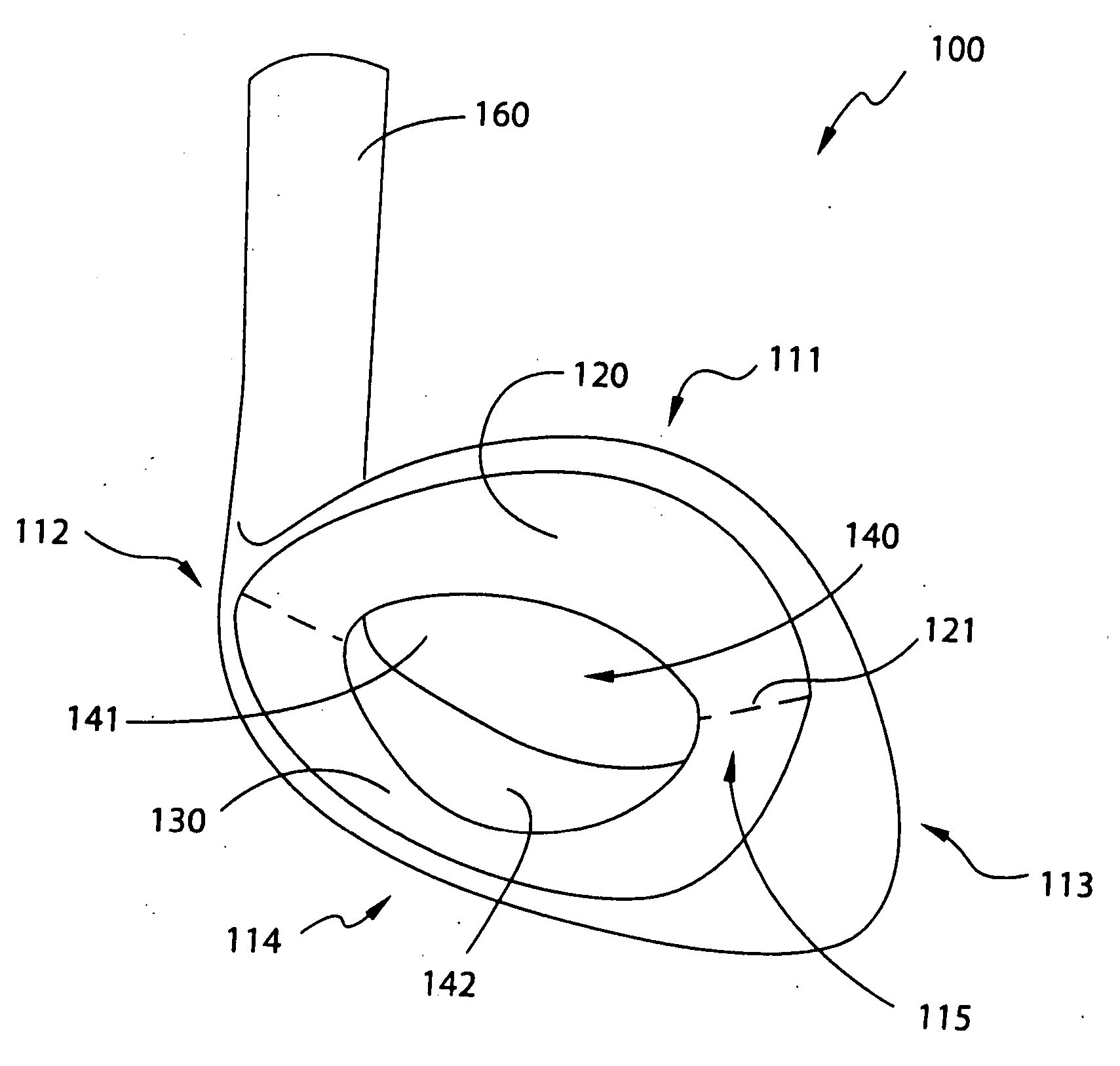

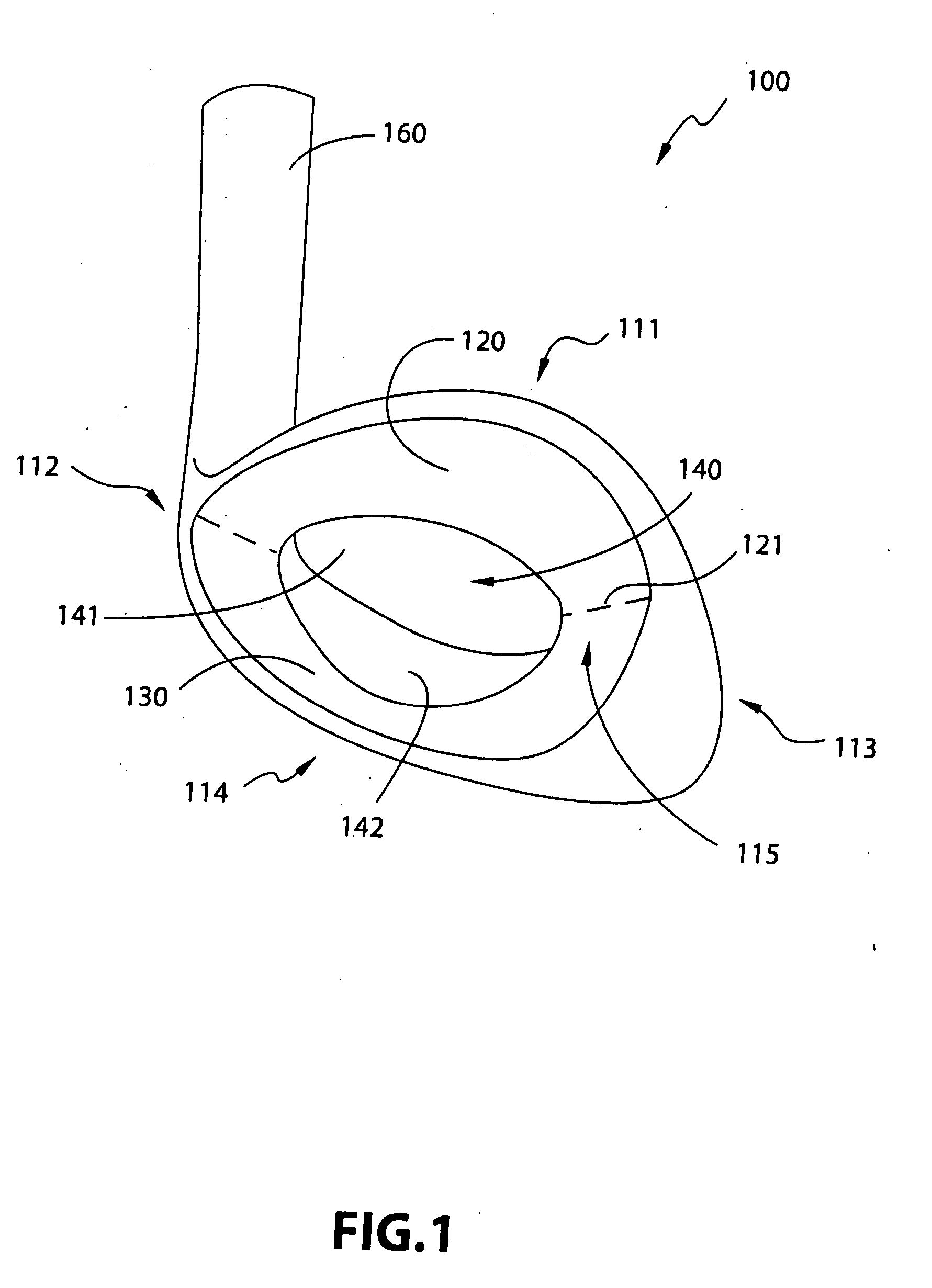

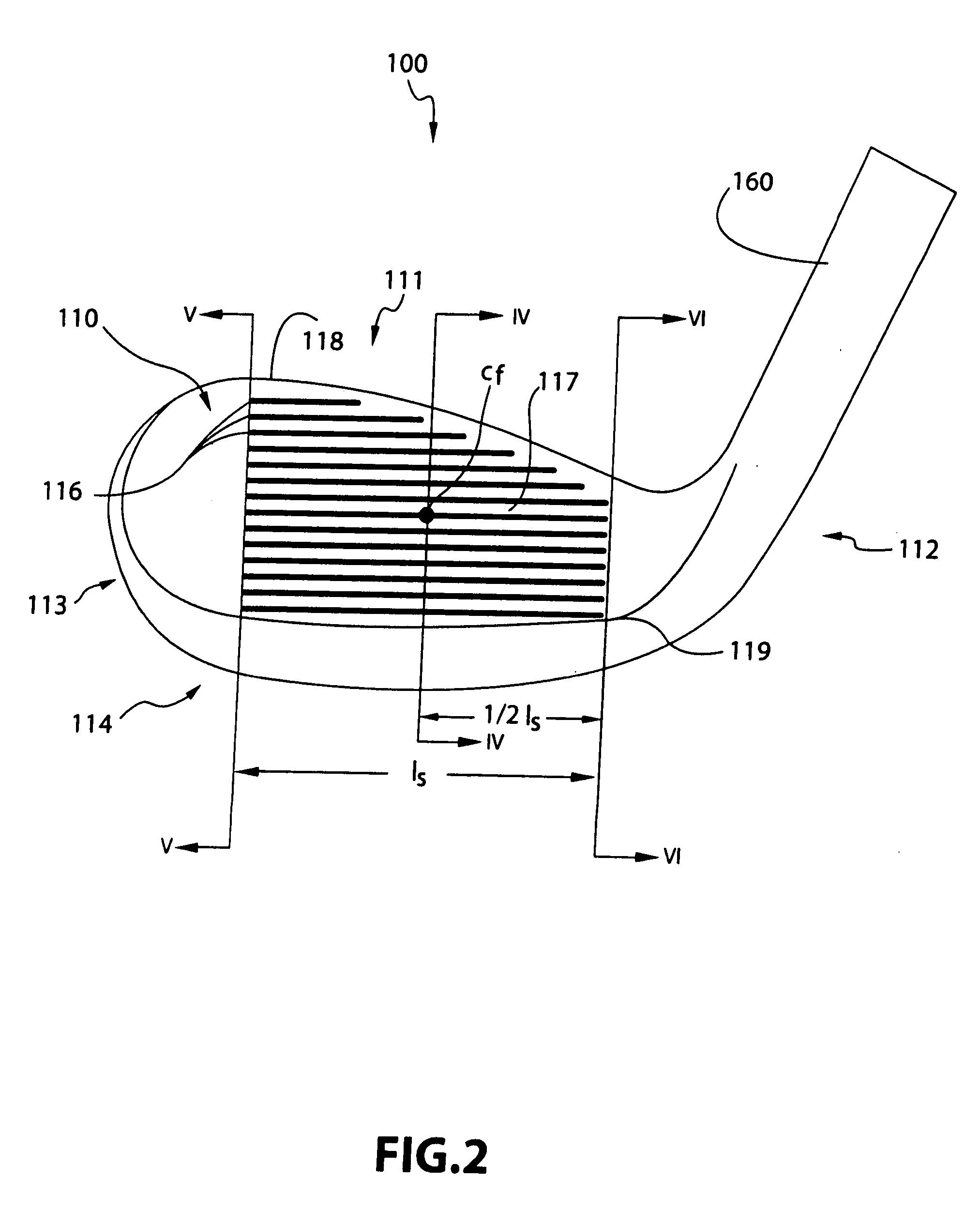

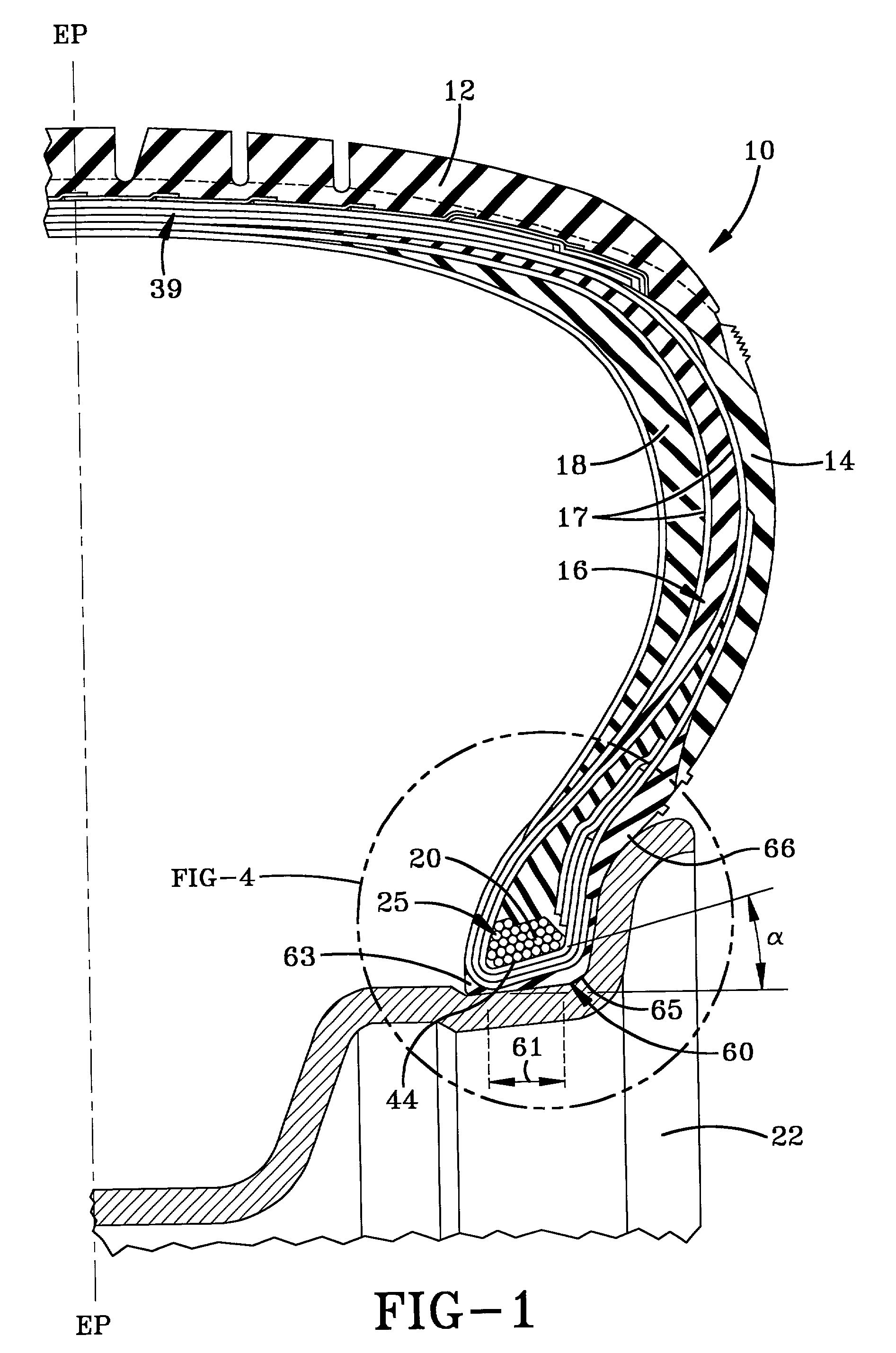

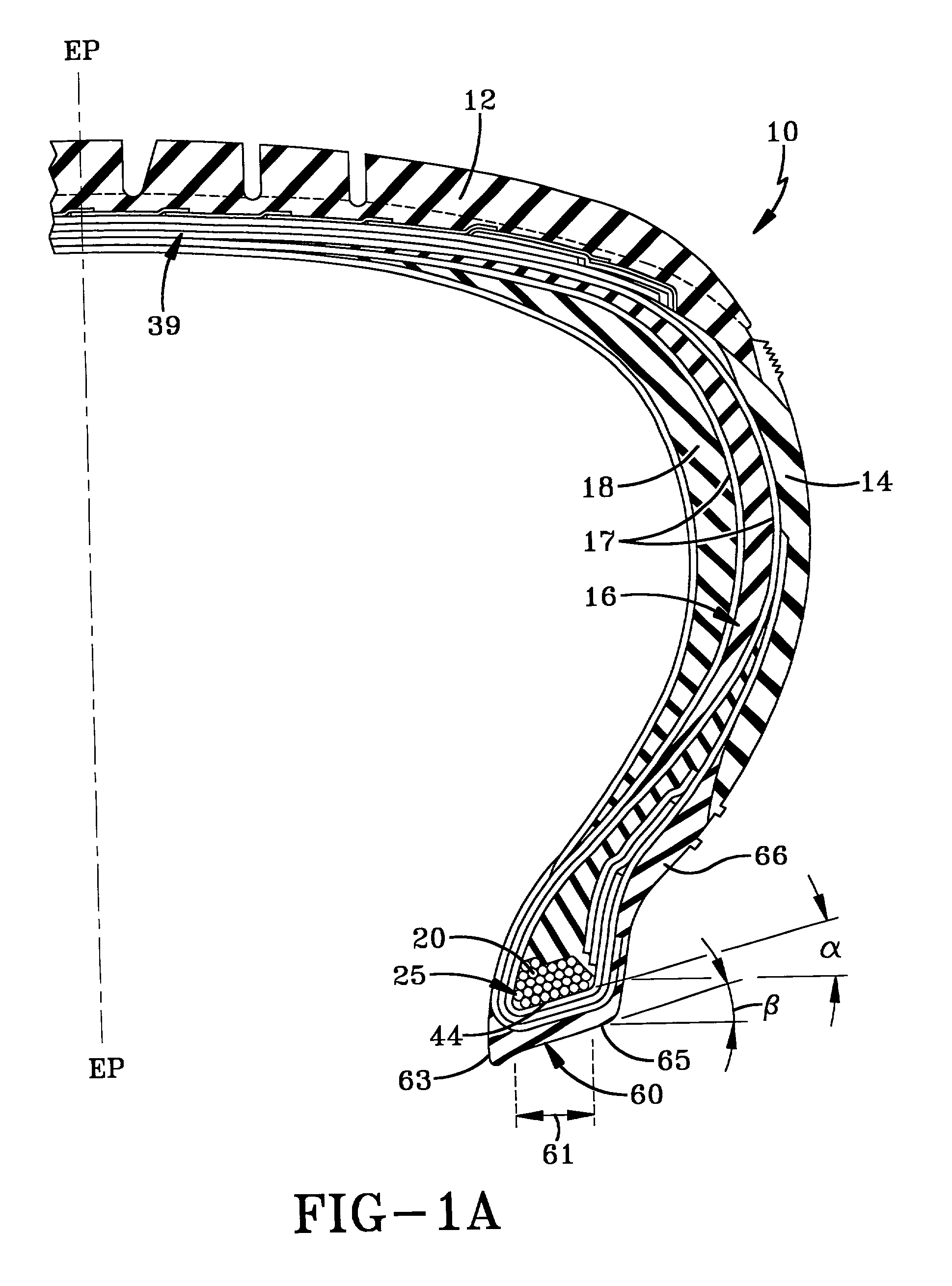

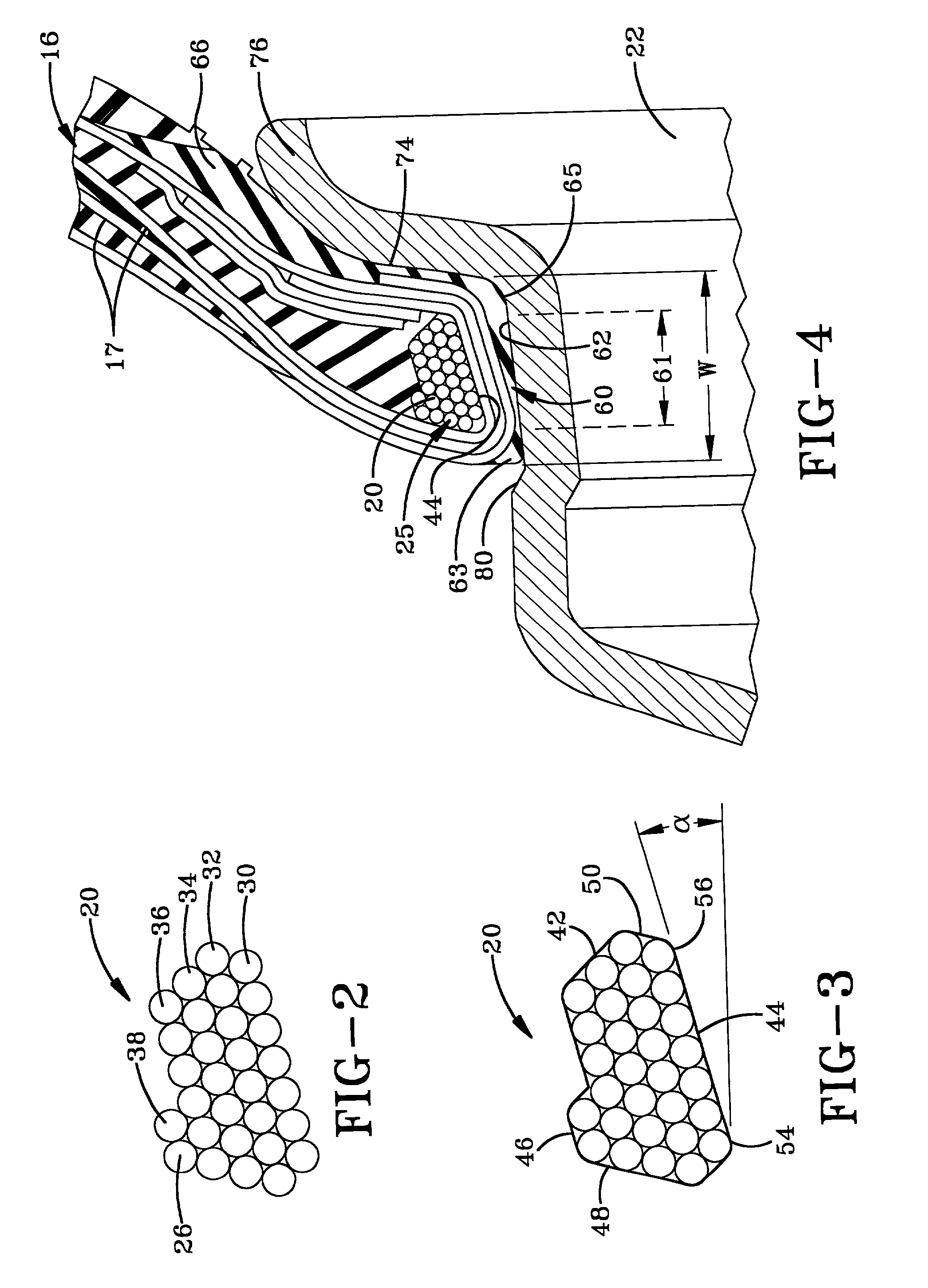

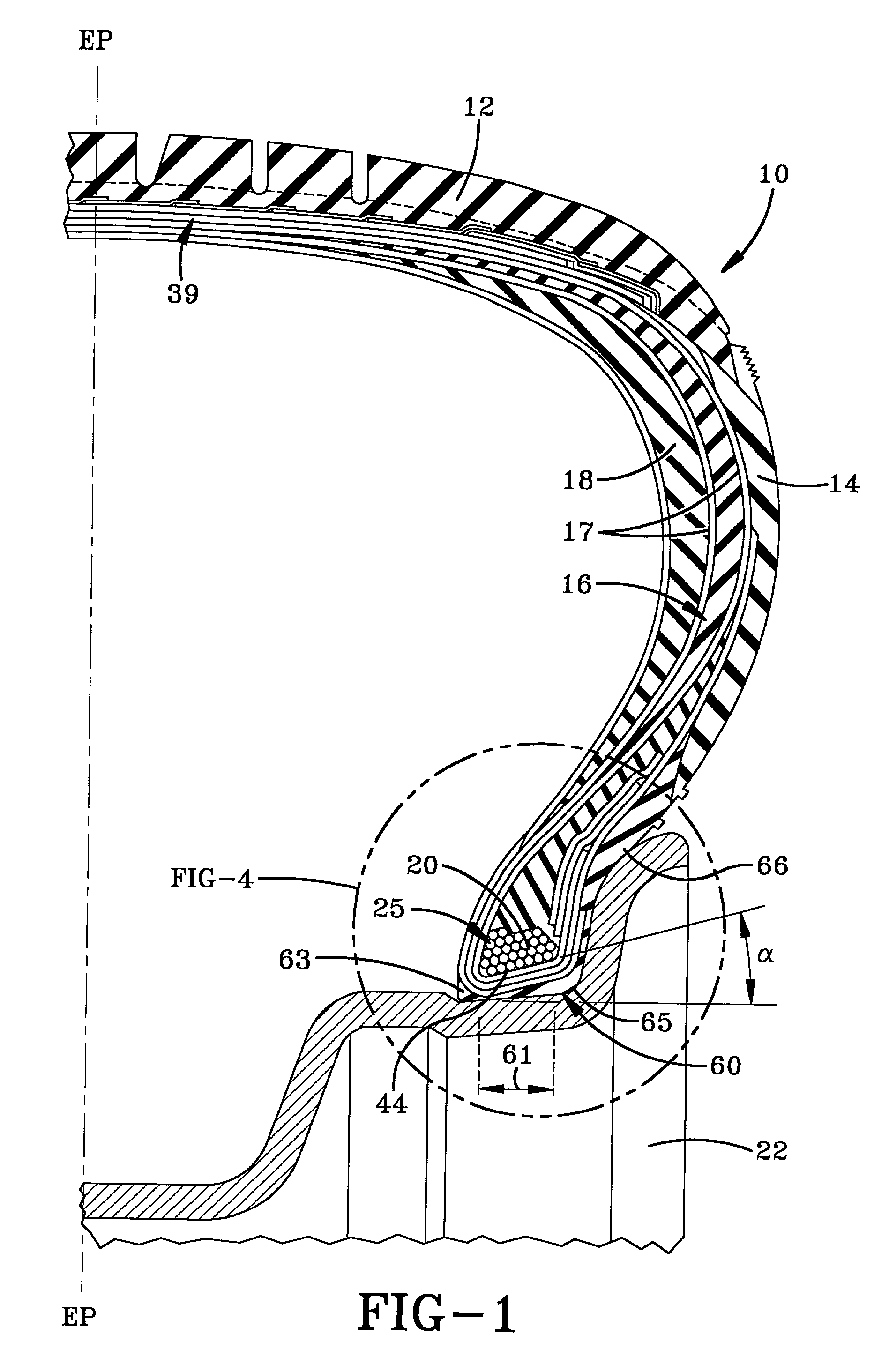

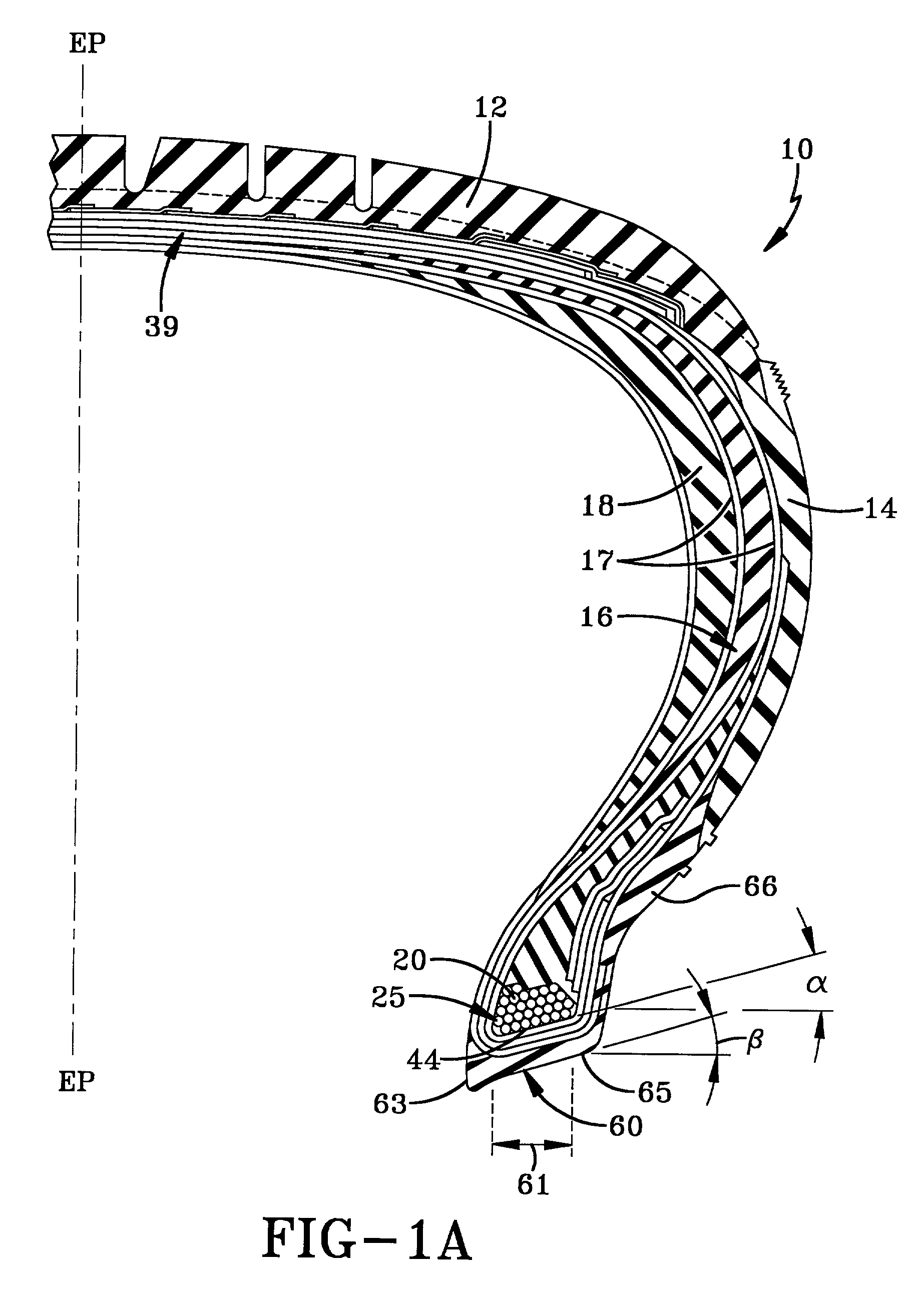

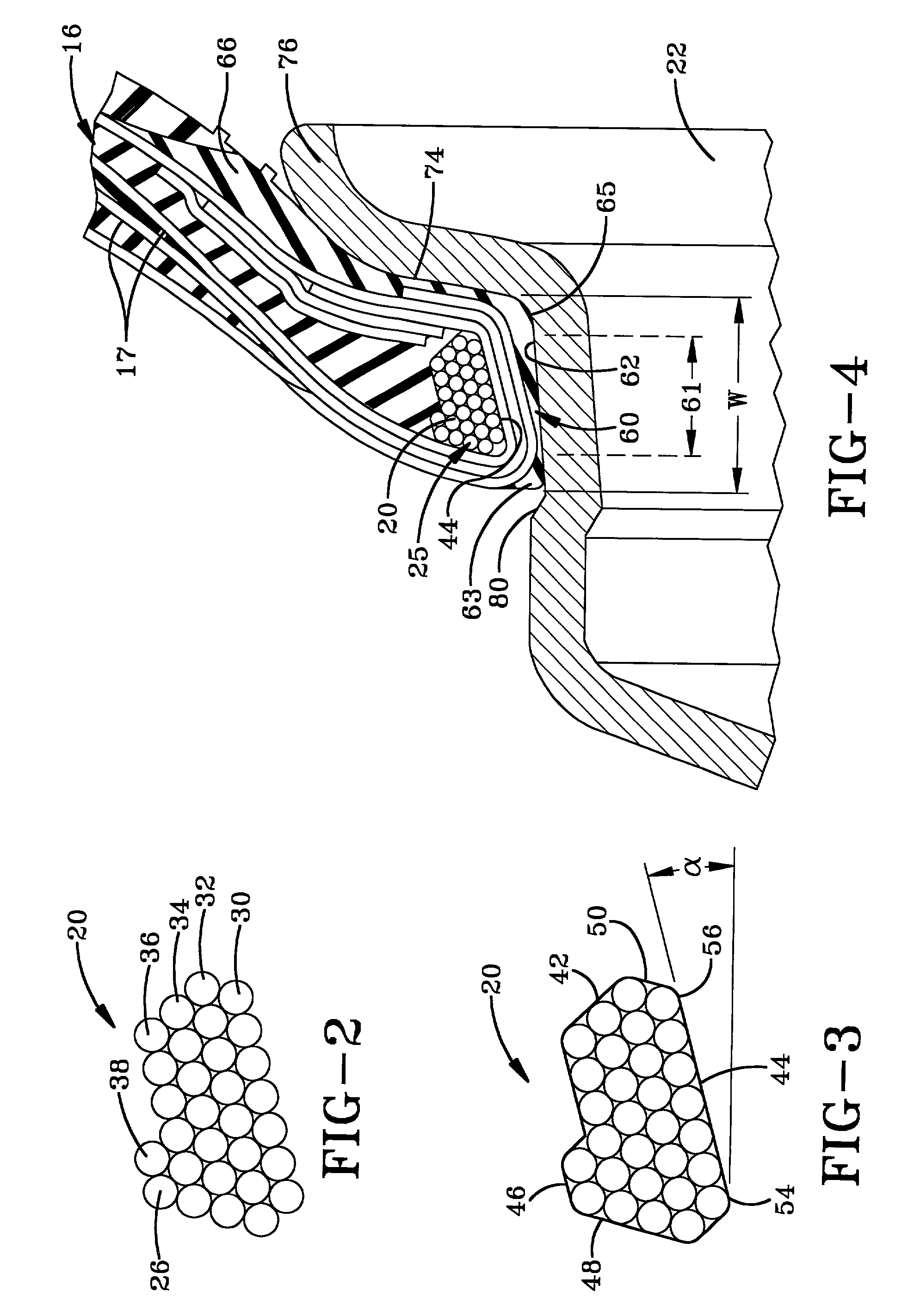

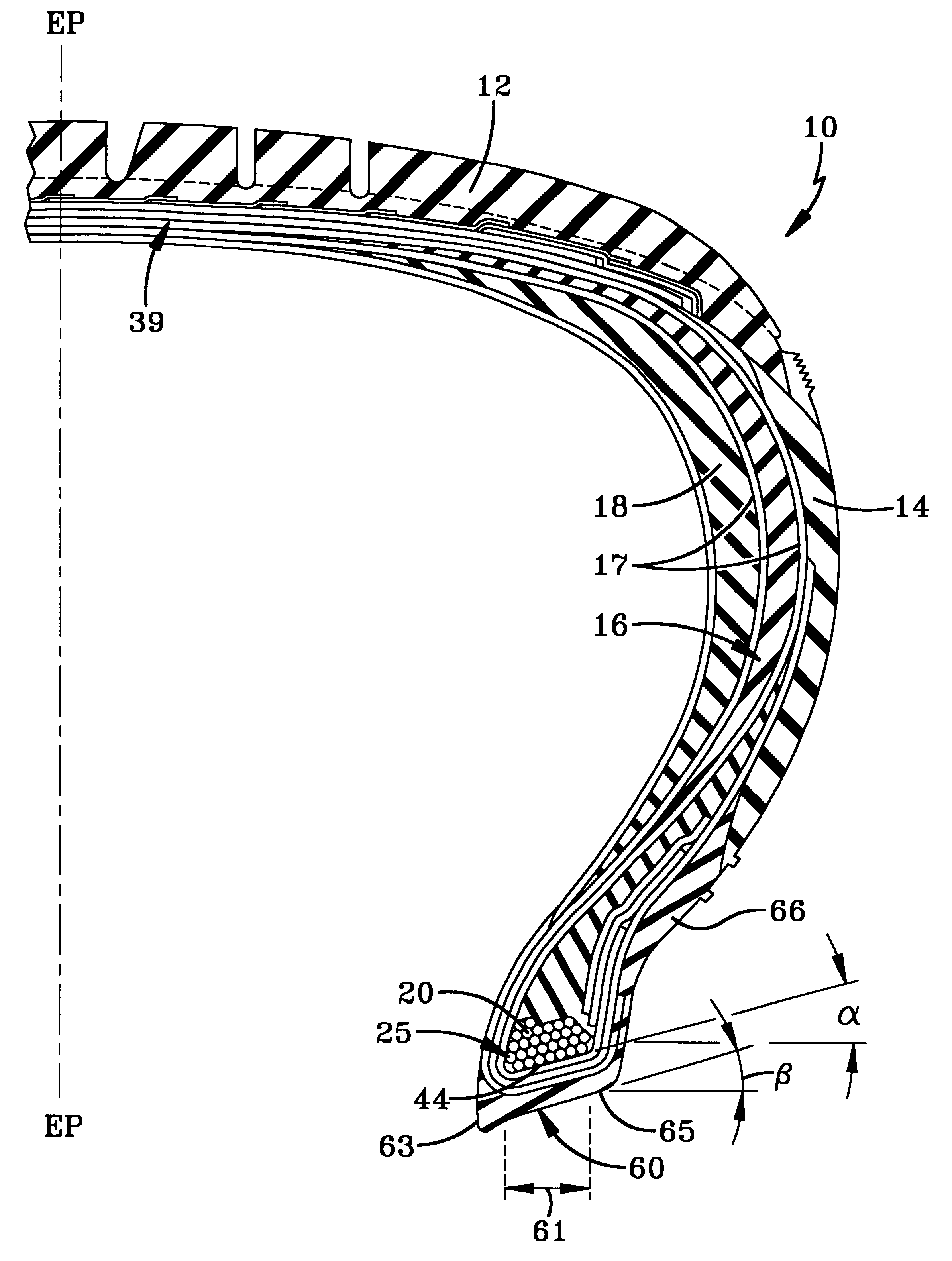

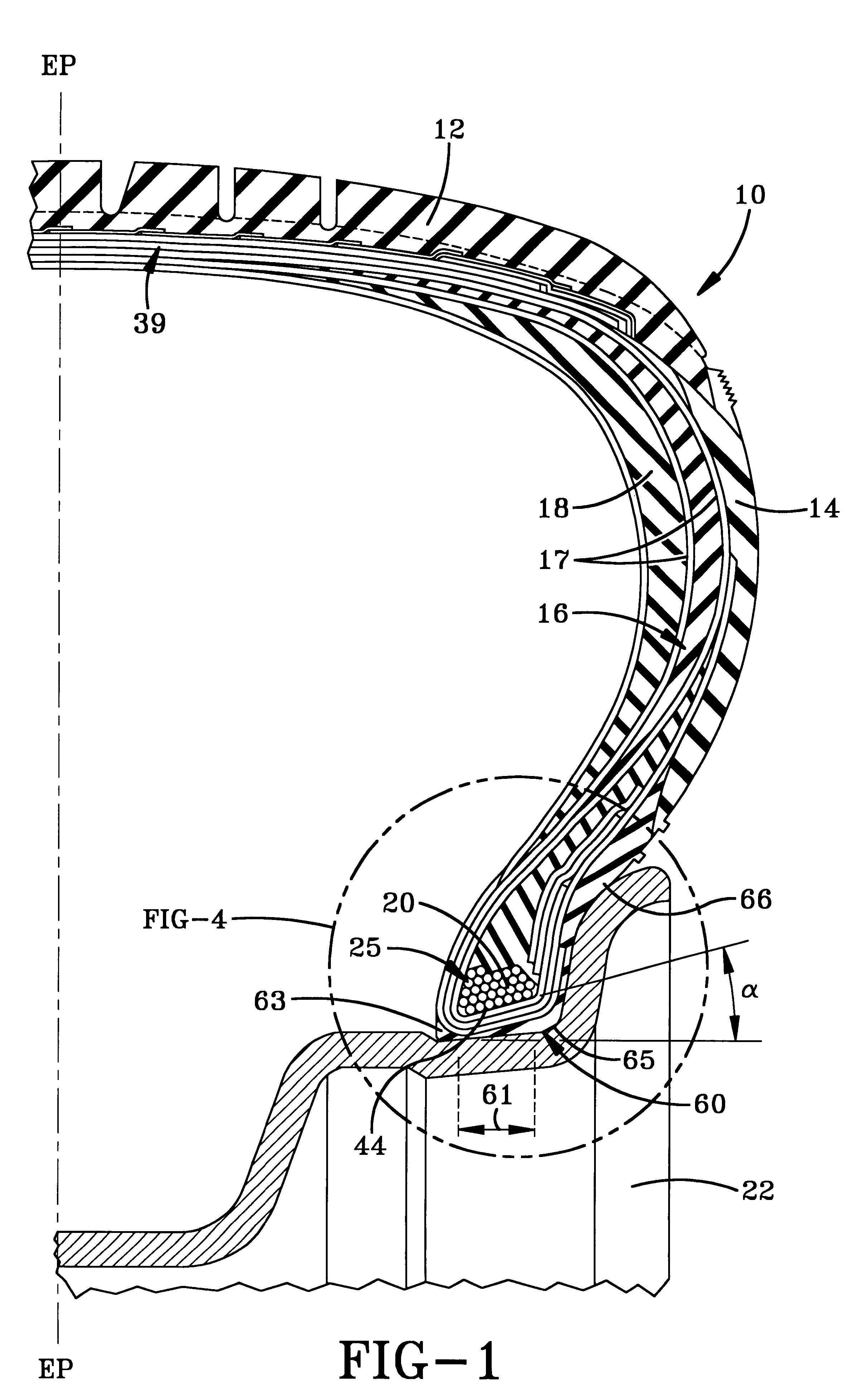

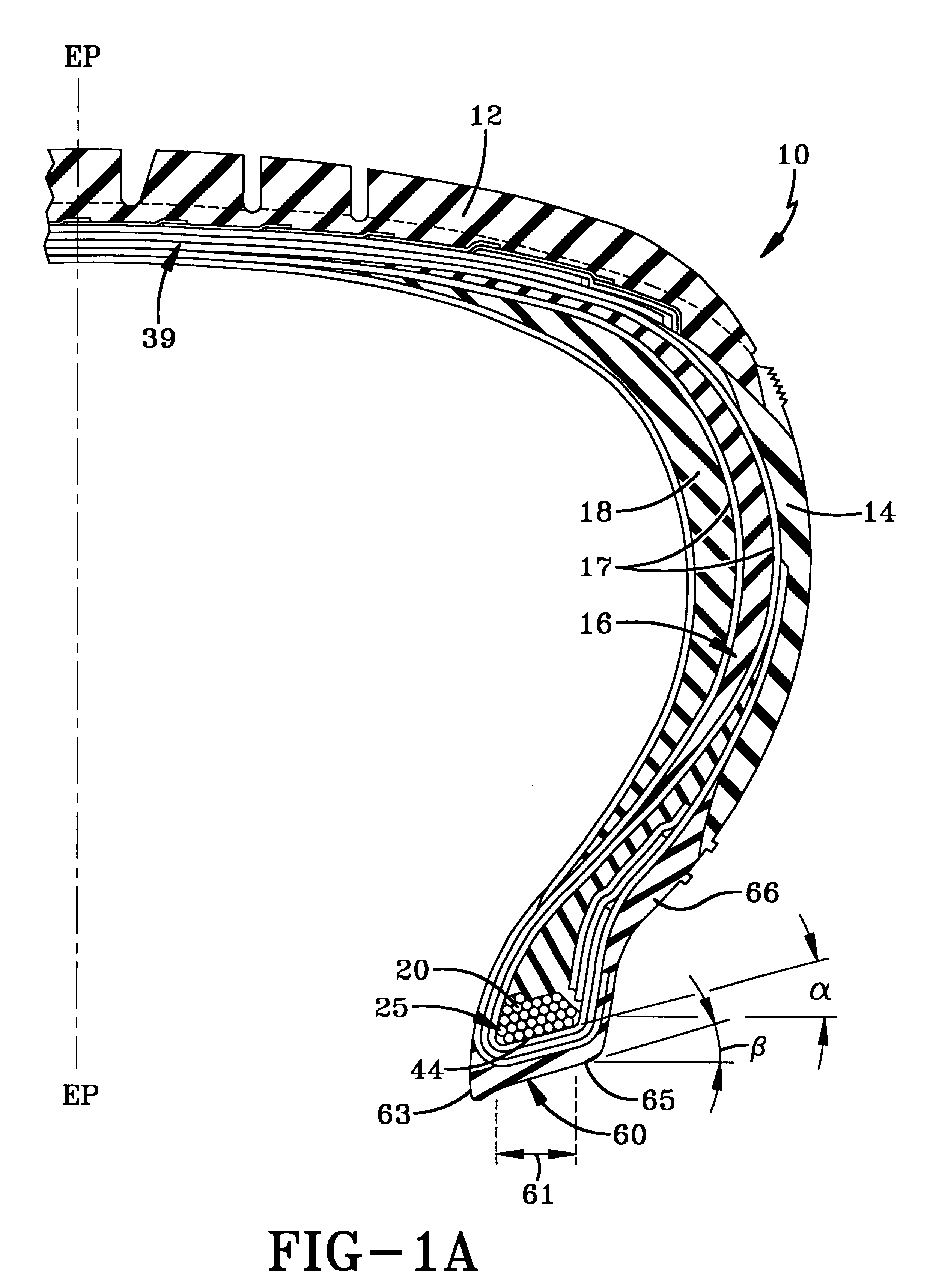

Pneumatic tire having specified bead structure

A radial ply pneumatic tire (10) features a bead core (20) which comprises an arrangement of filaments (26) positioned relative to one another. The bead core (20) has a cross-section and a radially inward base side (44), a radially outermost side (46), an axially inward first side (48), and an axially outward second side (50). In the cross section, the base side (44) of the bead core (20) has a width which is substantially linear and is between 50% to 75% of the rim seat width. The bead core base side (44) is inclined at least 15° relative to the bead's axis of rotation, while the bead heel surface has an as molded inclination at the central portion (61) radially inward of the bead base (44) at an angle of at least 10° with respect to the bead's axis. An associated rim (22) has a pair of humps (80) and a rim flange (76) associated with each hump (80). Each rim flange (76) has an axially inward surface (74), the distance between each hump (80) and the axially inward surface (74) of the associated rim flange (76) being a rim seat (62). The tire (10) further has a unique toeguard chafer (66) compound that is cut resistant.

Owner:THE GOODYEAR TIRE & RUBBER CO

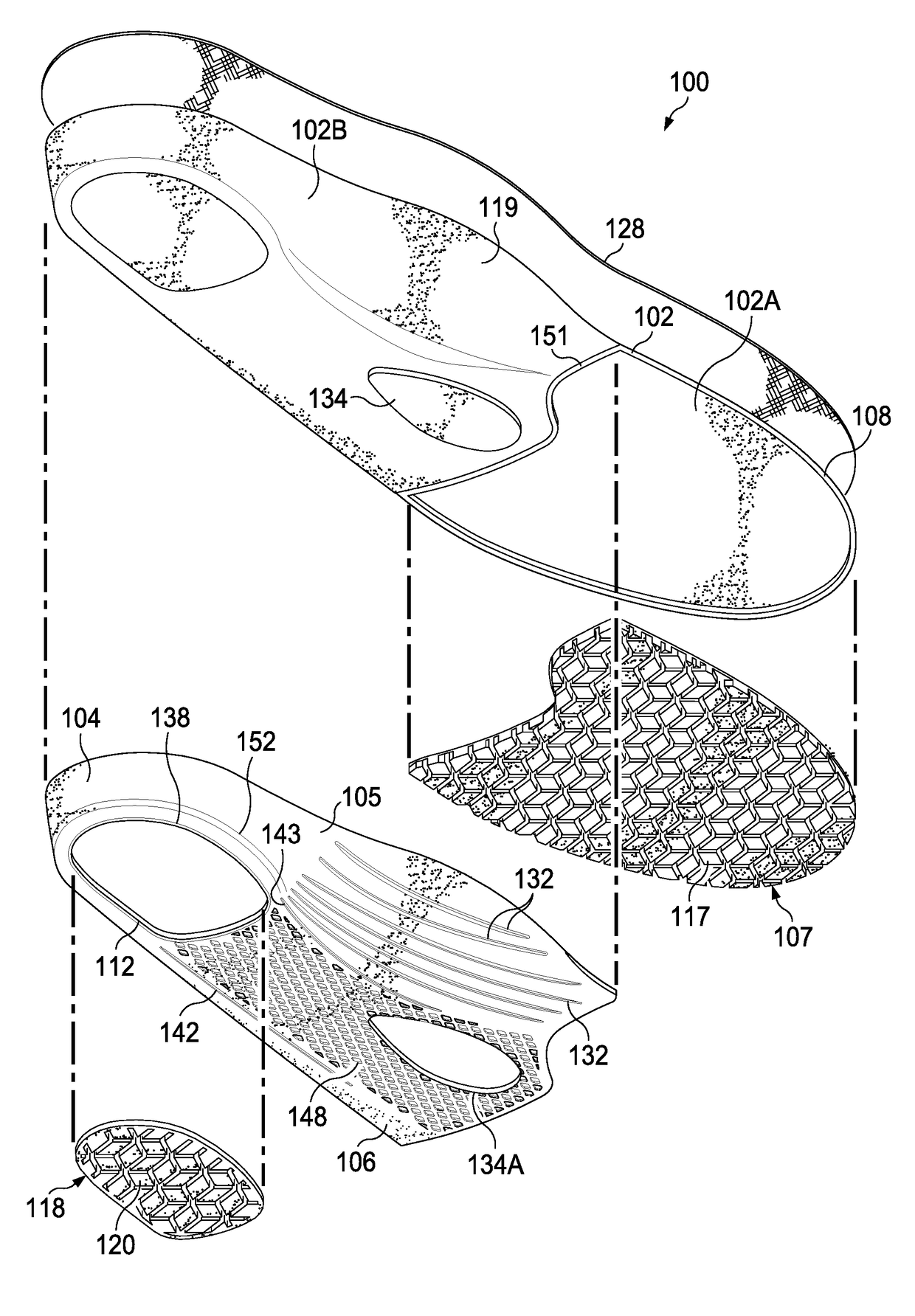

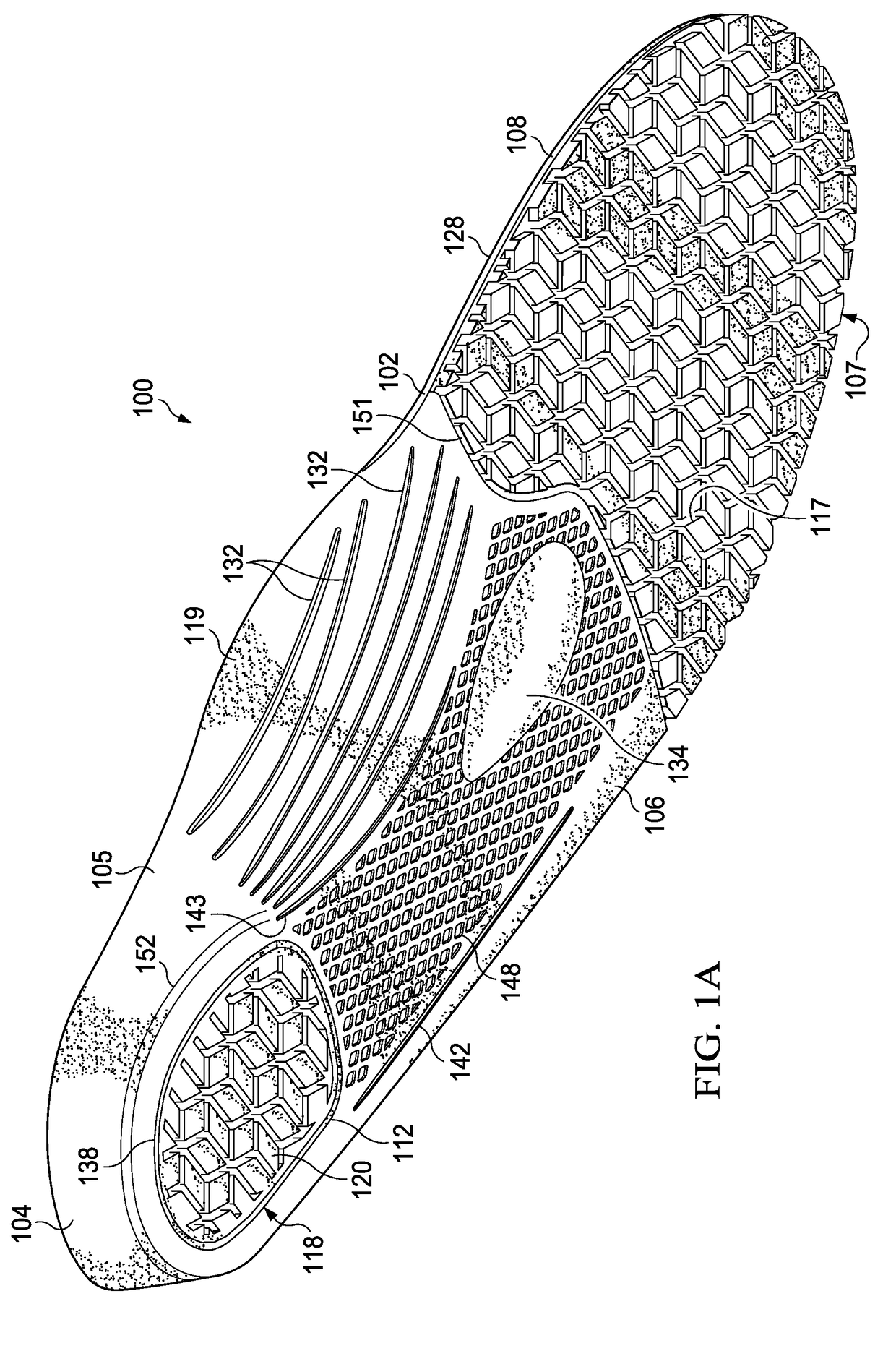

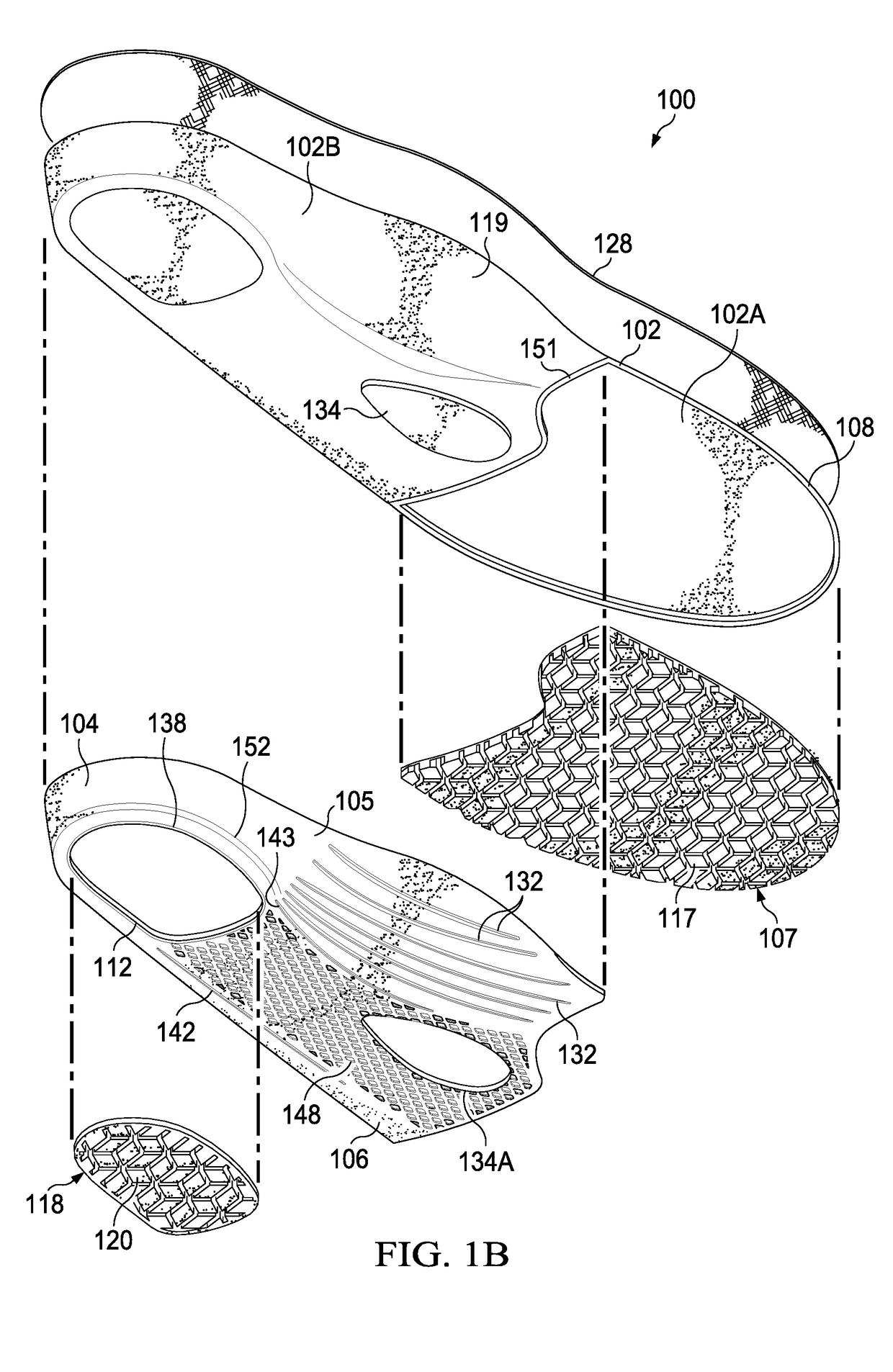

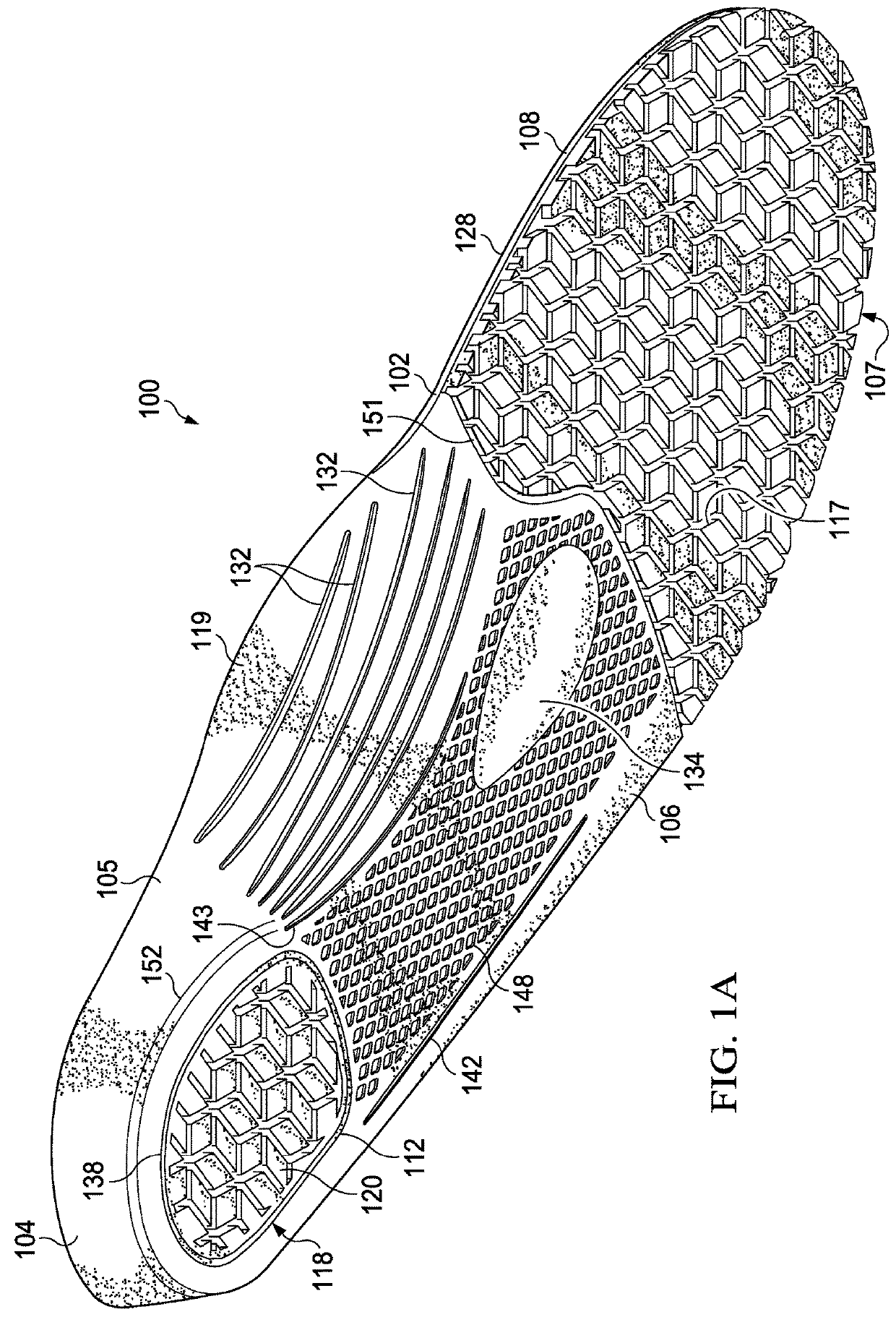

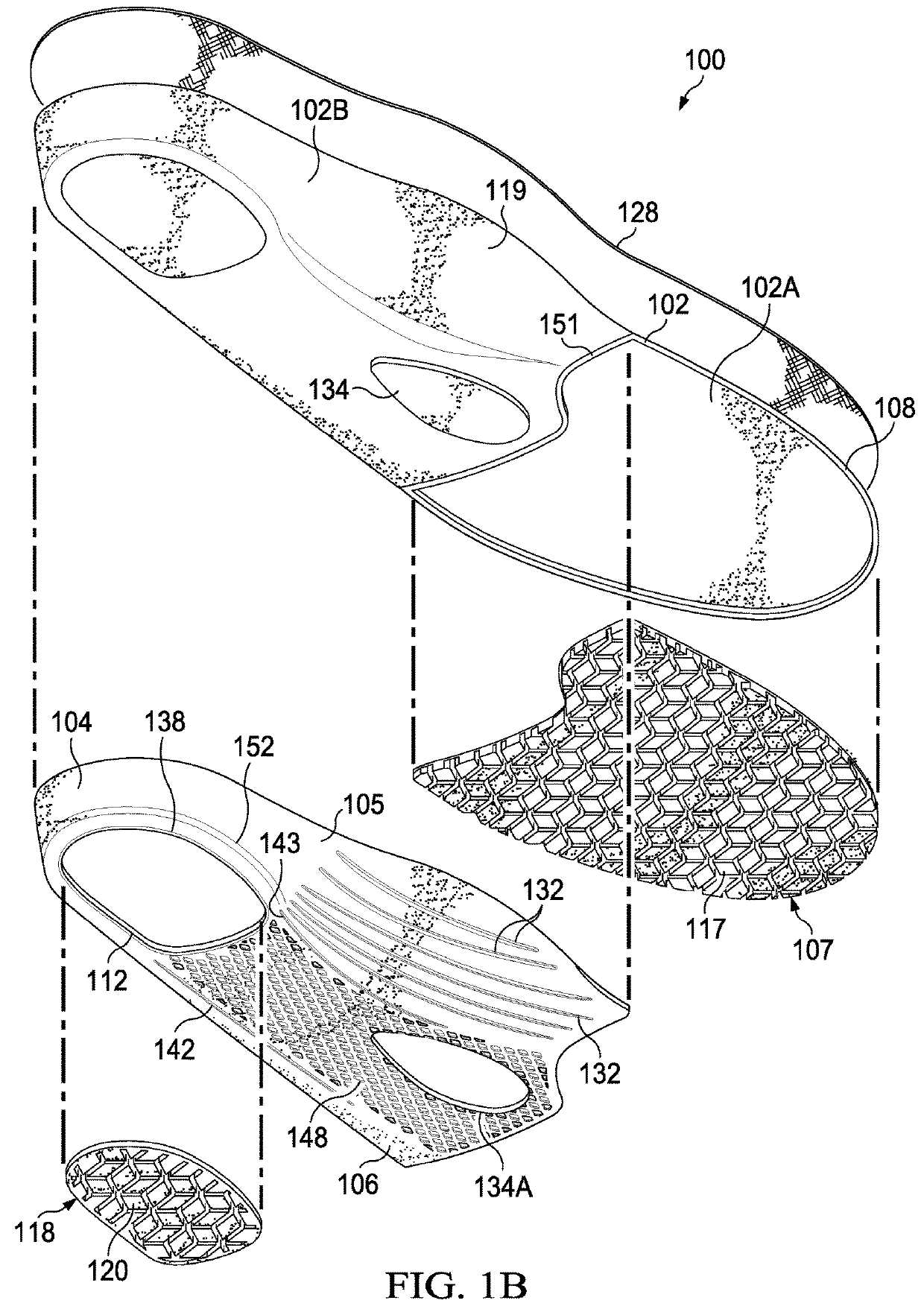

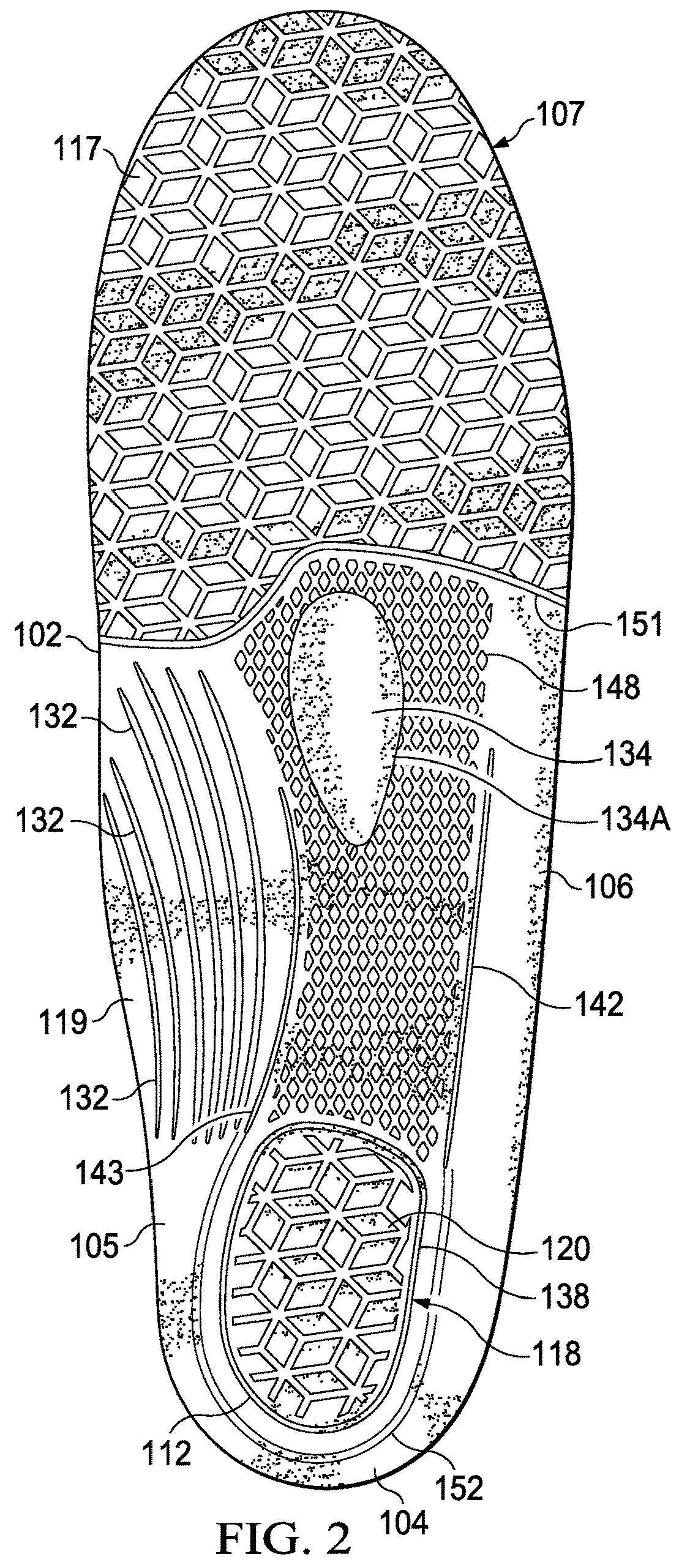

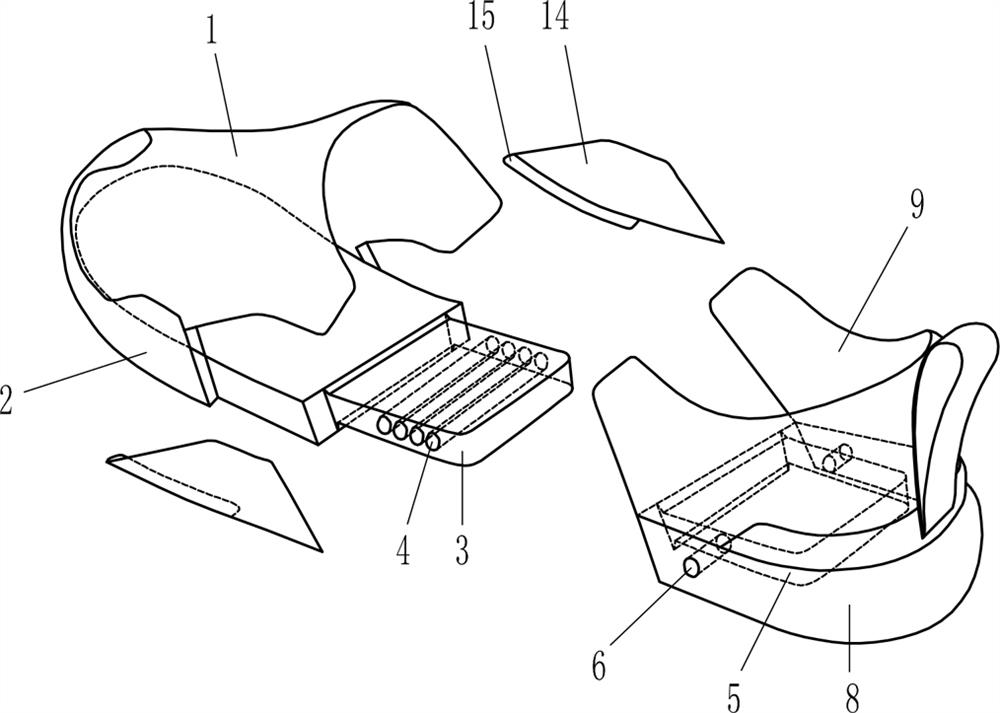

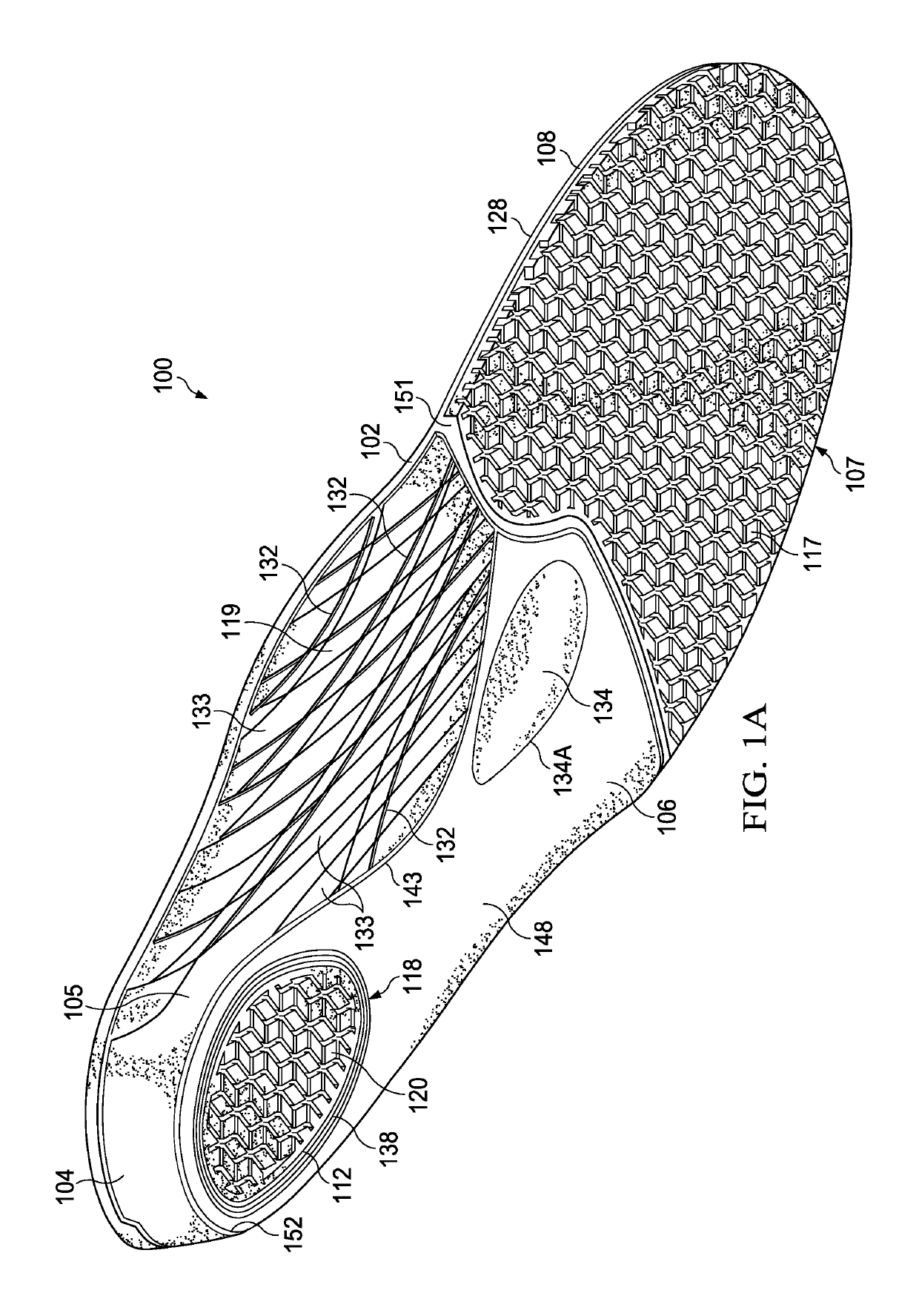

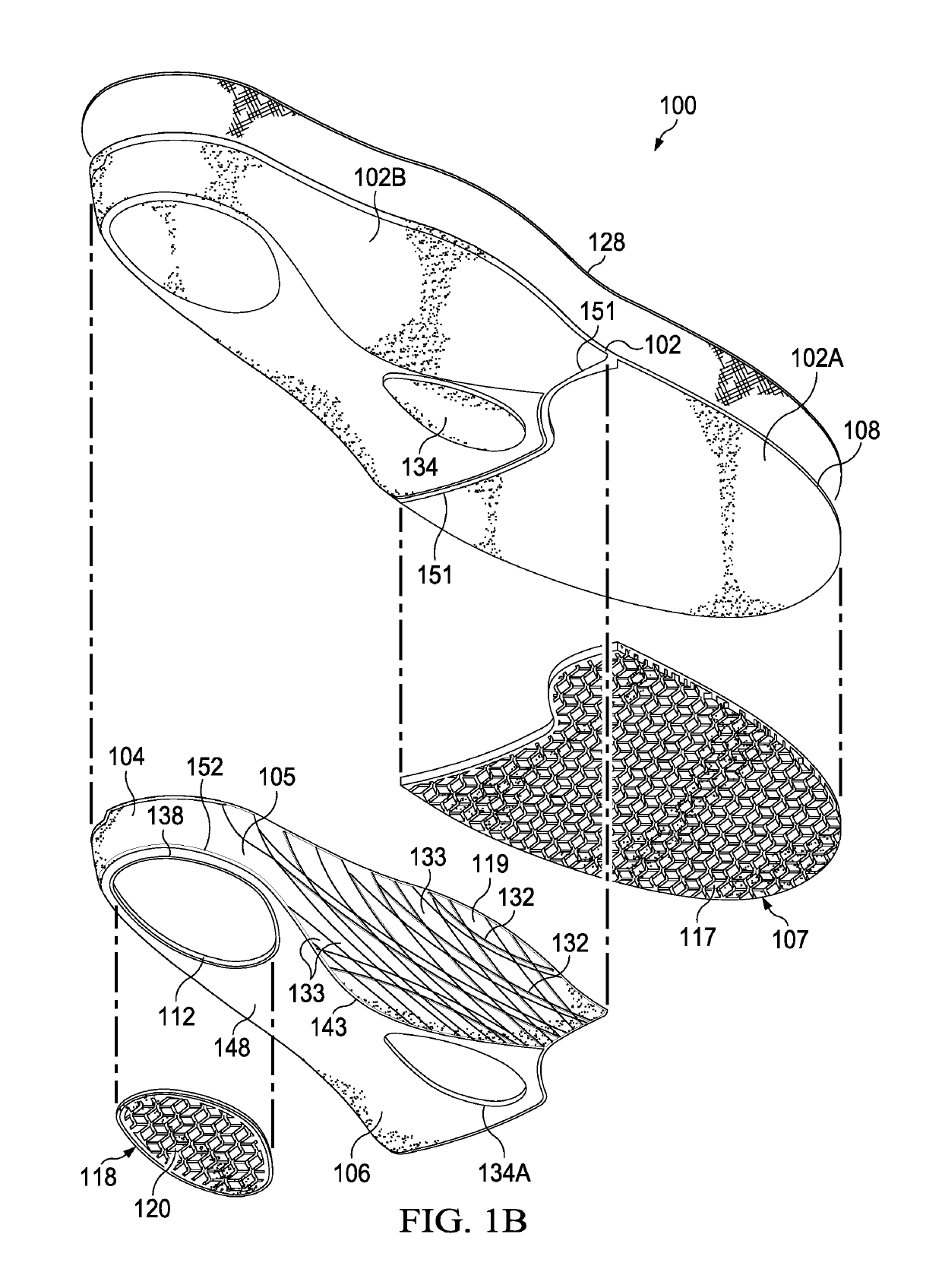

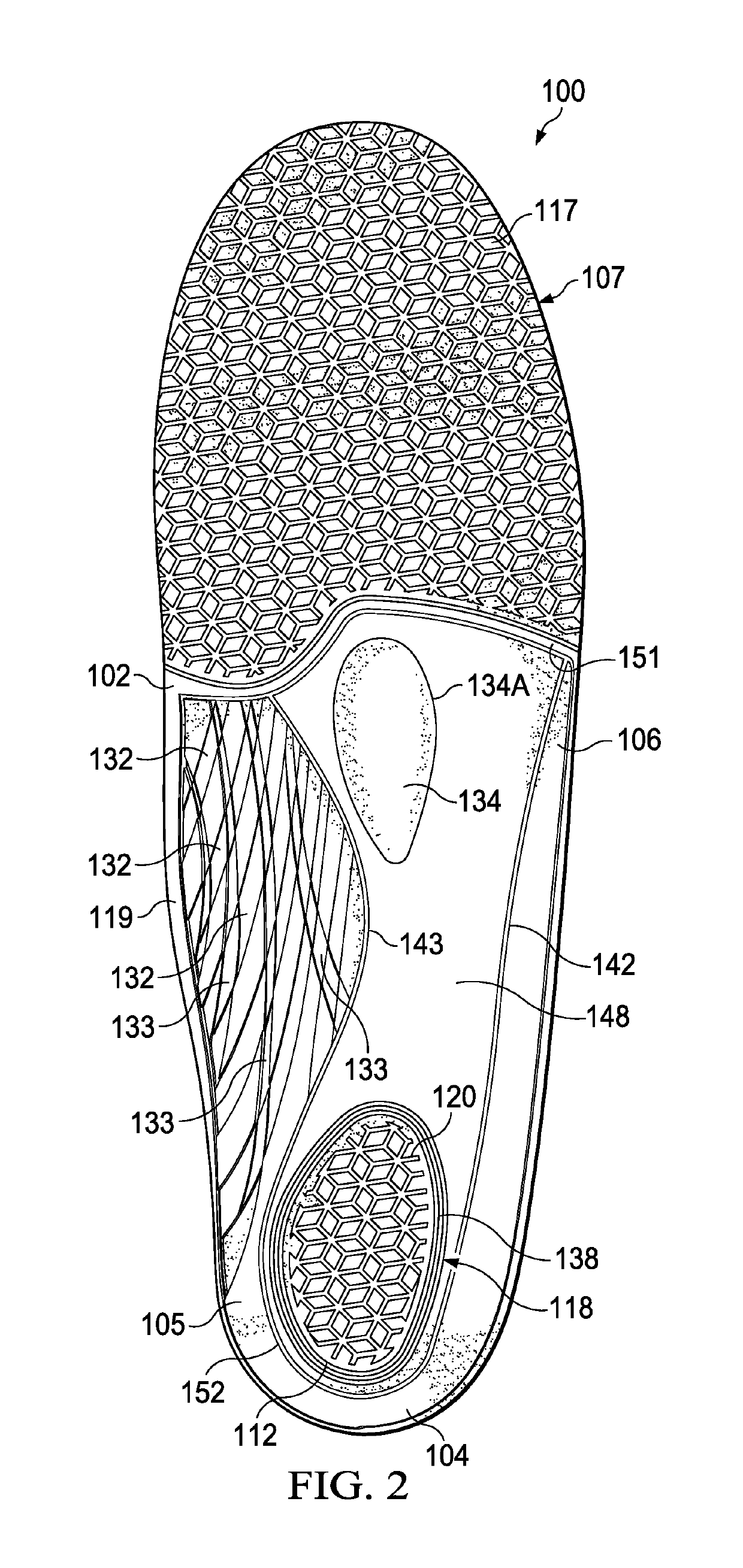

Contoured Support Shoe Insole

An insole having a top sheet and a base layer with three pieces that include a base layer, a forefoot pad and a midfoot-to-heel support cushion. The mid-foot / heel surface has a raised medial arch and longitudinal curvilinear indentations, a flattened mid-foot area with a metatarsal mid-foot tear-drop raised area, and a surrounding the heel pod that cups the exterior back by a heel cup. A heel pad opening goes through the entirety of the thickness of base layer of the insole body and a heel pad is affixed to the bottom surface of the base layer. There is also a supersoft heel dome and a metatarsal raised dome on the top (foot contact) surface of the insole which would be directly above the heel pod and the metatarsal midfoot area, respectively.

Owner:IMPLUS FOOTCARE

Contoured support shoe insole

An insole having a top sheet and a base layer with three pieces that include a base layer, a forefoot pad and a midfoot-to-heel support cushion. The mid-foot / heel surface has a raised medial arch and longitudinal curvilinear indentations, a flattened mid-foot area with a metatarsal mid-foot tear-drop raised area, and a surrounding the heel pod that cups the exterior back by a heel cup. A heel pad opening goes through the entirety of the thickness of base layer of the insole body and a heel pad is affixed to the bottom surface of the base layer. There is also a supersoft heel dome and a metatarsal raised dome on the top (foot contact) surface of the insole which would be directly above the heel pod and the metatarsal midfoot area, respectively.

Owner:IMPLUS FOOTCARE

Pneumatic tire having specified bead structure

A radial ply pneumatic tire (10) features a bead core (20) which comprises an arrangement of filaments (26) positioned relative to one another. The bead core (20) has a cross-section and a radially inward base side (44), a radially outermost side (46), an axially inward first side (48), and an axially outward second side (50). In the cross section, the base side (44) of the bead core (20) has a width which is substantially linear and is between 50% to 75% of the rim seat width. The bead core base side (44) is inclined at least 15° relative to the bead's axis of rotation, while the bead heel surface has an as molded inclination at the central portion (61) radially inward of the bead base (44) at an angle of at least 10° with respect to the bead's axis. An associated rim (22) has a pair of humps (80) and a rim flange (76) associated with each hump (80). Each rim flange (76) has an axially inward surface (74), the distance between each hump (80) and the axially inward surface (74) of the associated rim flange (76) being a rim seat (62). The tire (10) further has a unique toeguard chafer (66) compound that is cut resistant.

Owner:THE GOODYEAR TIRE & RUBBER CO

Pneumatic tire having specified bead structure

A radial ply pneumatic tire (10) features a bead core (20) which comprises an arrangement of filaments (26) positioned relative to one another. The bead core (20) has a cross-section and a radially inward base side (44). In the cross section, the base side (44) of the bead core (20) has a width which is substantially linear and is between 50% to 75% of the rim seat width. The bead core base side (44) is inclined at least 15° relative to the bead's axis of rotation, while the bead heel surface has an as molded inclination at the central portion (61) radially inward of the bead base (44) at an angle of at least 10° with respect to the bead's axis. The tire (10) further has a unique toeguard chafer (66) compound that is cut resistant.

Owner:THE GOODYEAR TIRE & RUBBER CO

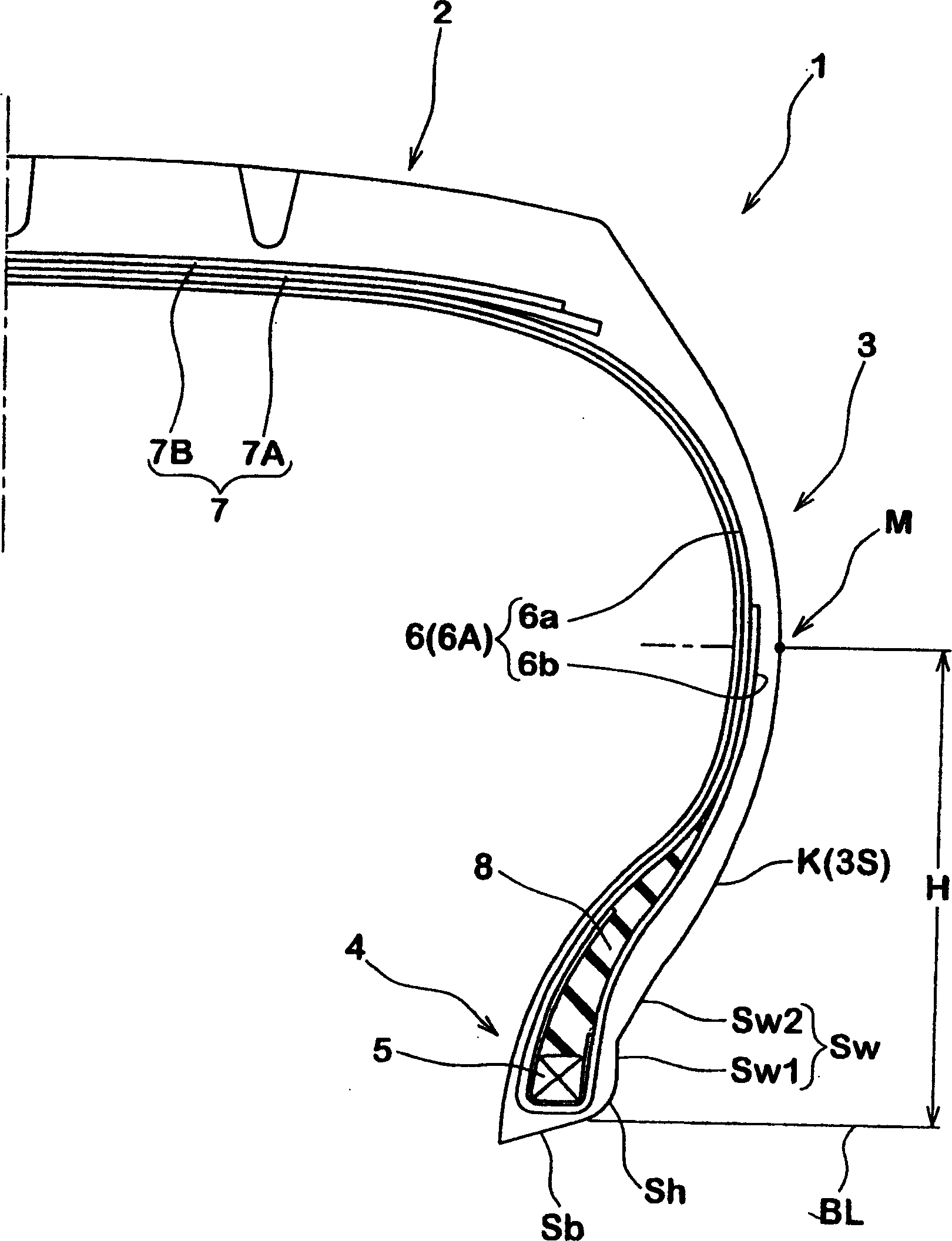

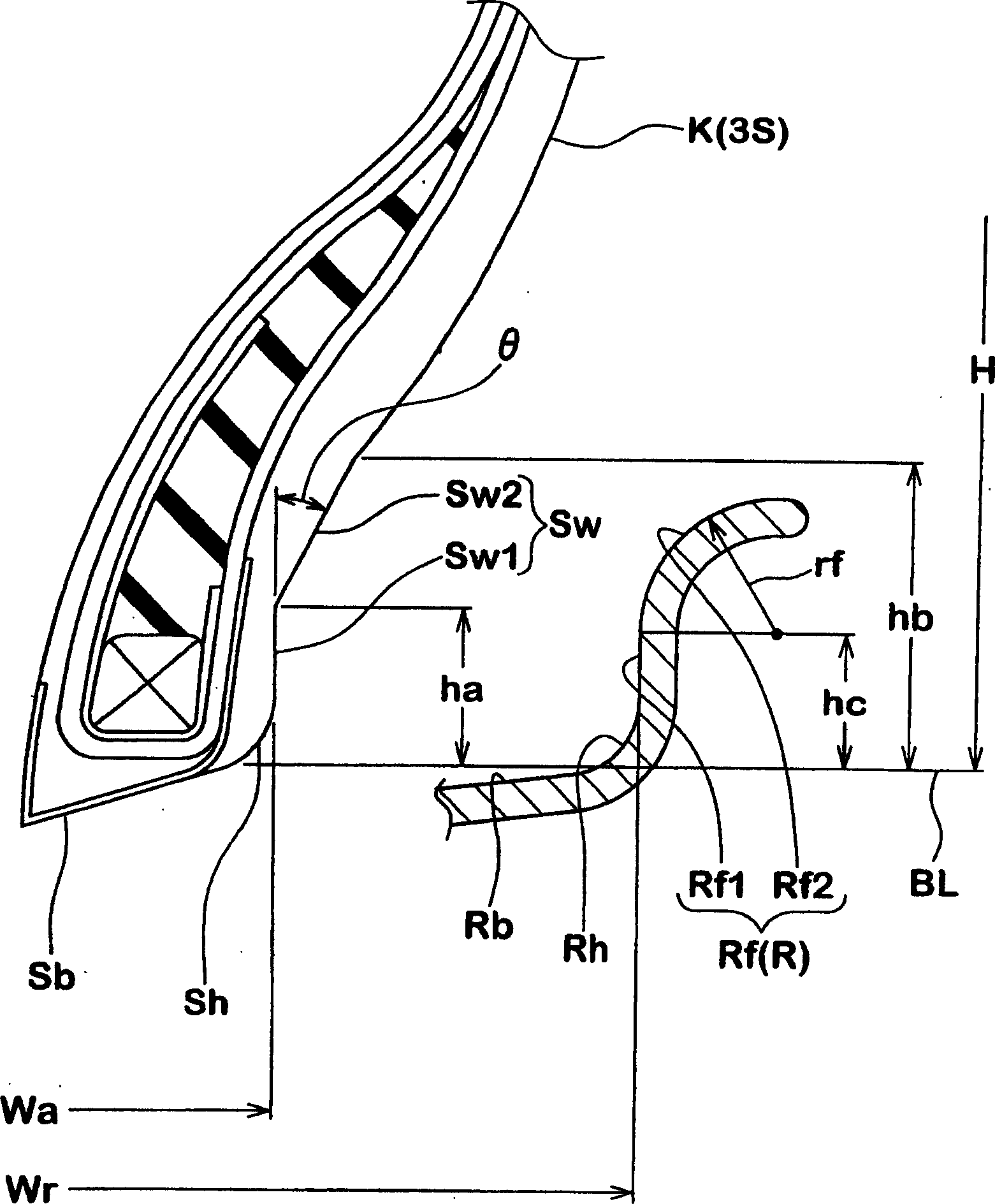

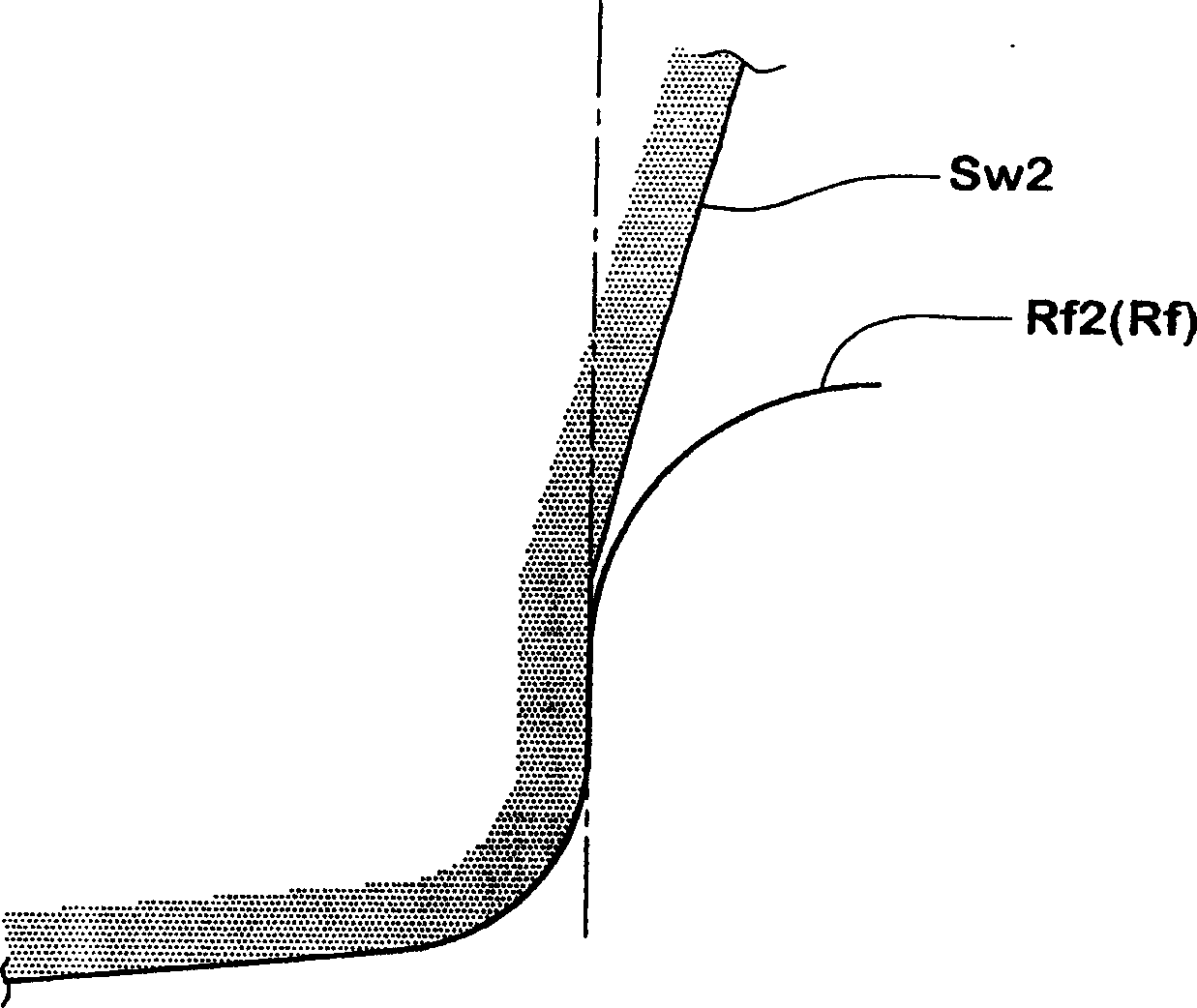

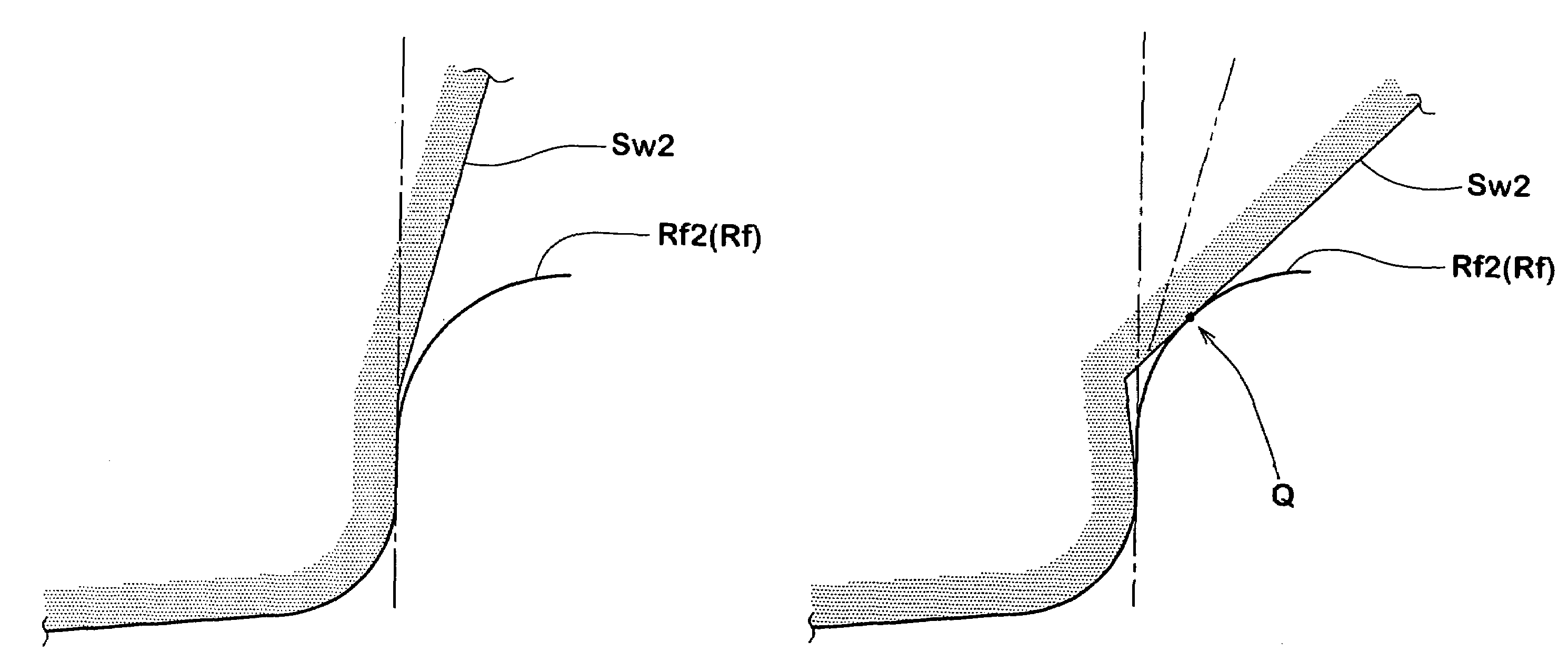

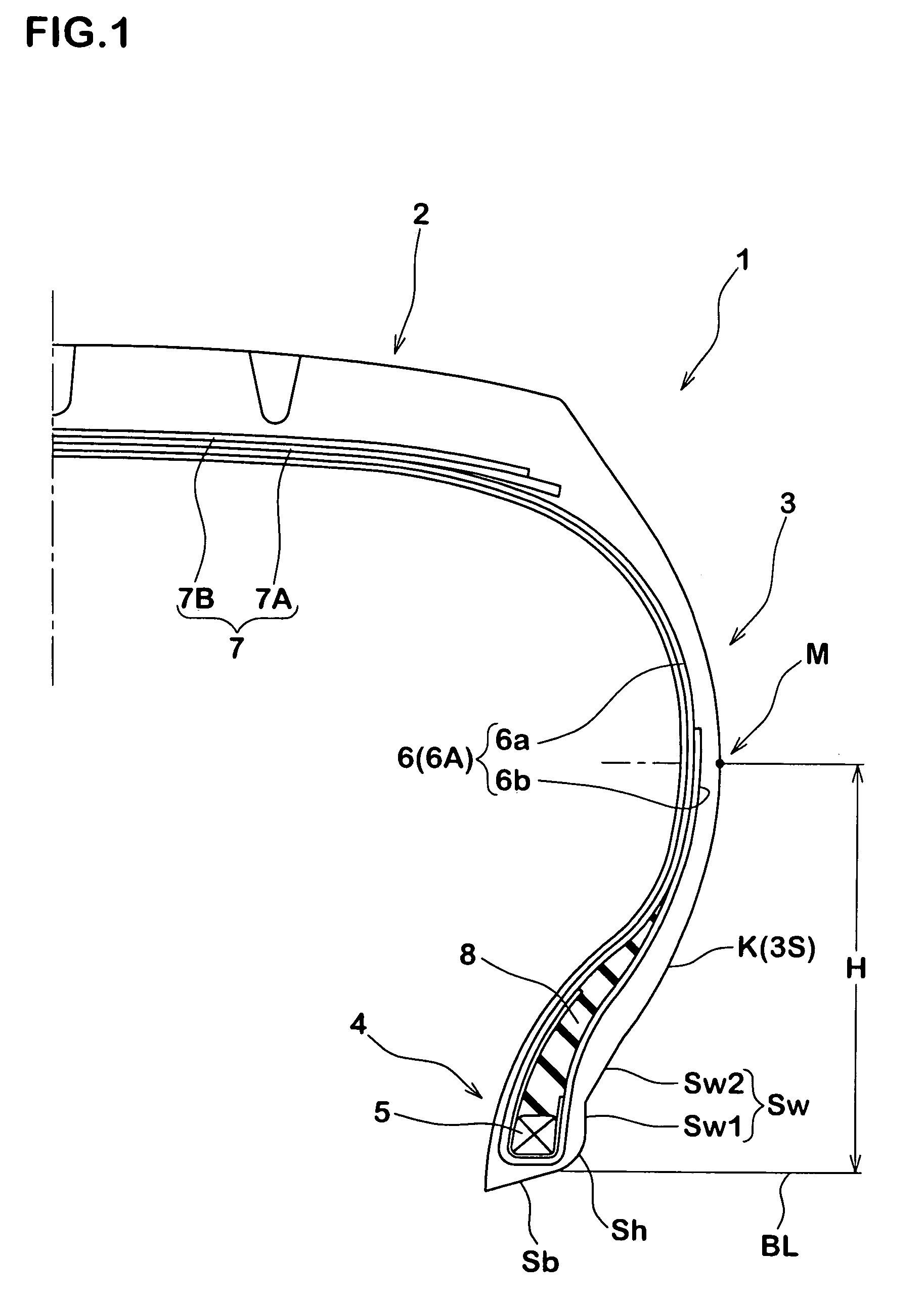

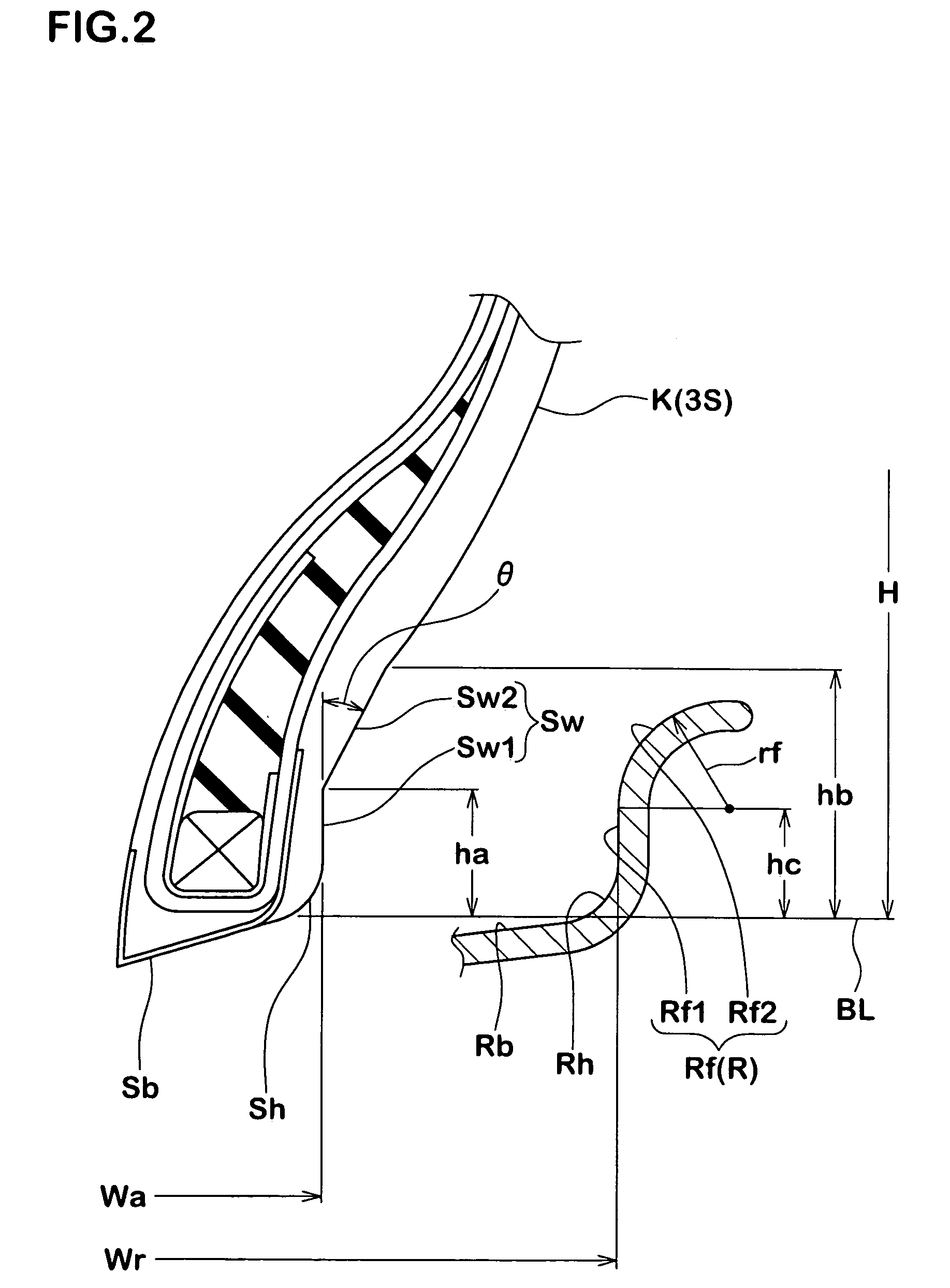

Pneumatic tire

InactiveCN1672966AImprove bindingImprove handling stabilityTyre beadsWheelsInternal pressureNormal load

A bead portion 4 of a pneumatic tire 1 includes a vertical rising surface portion which is connected to a bead base surface Sb through an arc bead heel surface Sh, and a straight or convex arc flange receiving surface portion Sw 2 which is diagonally extending from the rising surface portion radially outward and axially outward of the tire. In a normal internal pressure in which no load is applied, the flange receiving surface portion Sw 2 is not in contact with a flange surface Rf, and in a load state in which 50% or more of normal load is applied, the flange receiving surface portion Sw comes into contact with the flange surface Rf.

Owner:SUMITOMO RUBBER IND LTD

Processing method based on shaping natural bottom leather shoe heel upper leather

InactiveCN104207413AStable structureSolve issues that impact production qualityShoemaking devicesFiberBristle

The invention discloses a processing method based on shaping natural bottom leather shoe heel upper leather. The method comprises the following steps of enabling the thickness of the shoe heel upper leather to be uniform and consistent through a flattening cutter machine; using a standard copying mould to mill the edges of the shoe heel upper leather, directly sand grinding the long heel surface through a grinding machine, and milling other unnecessary periphery on a platform copying mould milling bottom edge machine after fixing the shoe heel upper leather on the copying mould; enabling a paraffin block to lean against a rotary bristle brush wheel or a cloth wheel, enabling paraffin scraps to be adhered to the rotary bristle brush wheel or the cloth wheel, polishing the shoe heel upper leather, and enabling the paraffin scraps to melt through friction heat and permeating into hide fiber; brush coating soapy water and polishing again if leather color needs to be deepened. According to the processing method, the processing process is designed based on the consideration of material particularity of the natural bottom leather, so that the structure of the shoe heel area is stable, the surface quality and the inside quality meet the design requirement, and the quality of the shoes meet the requirement.

Owner:CHENGDU KAMEIDO SHOES

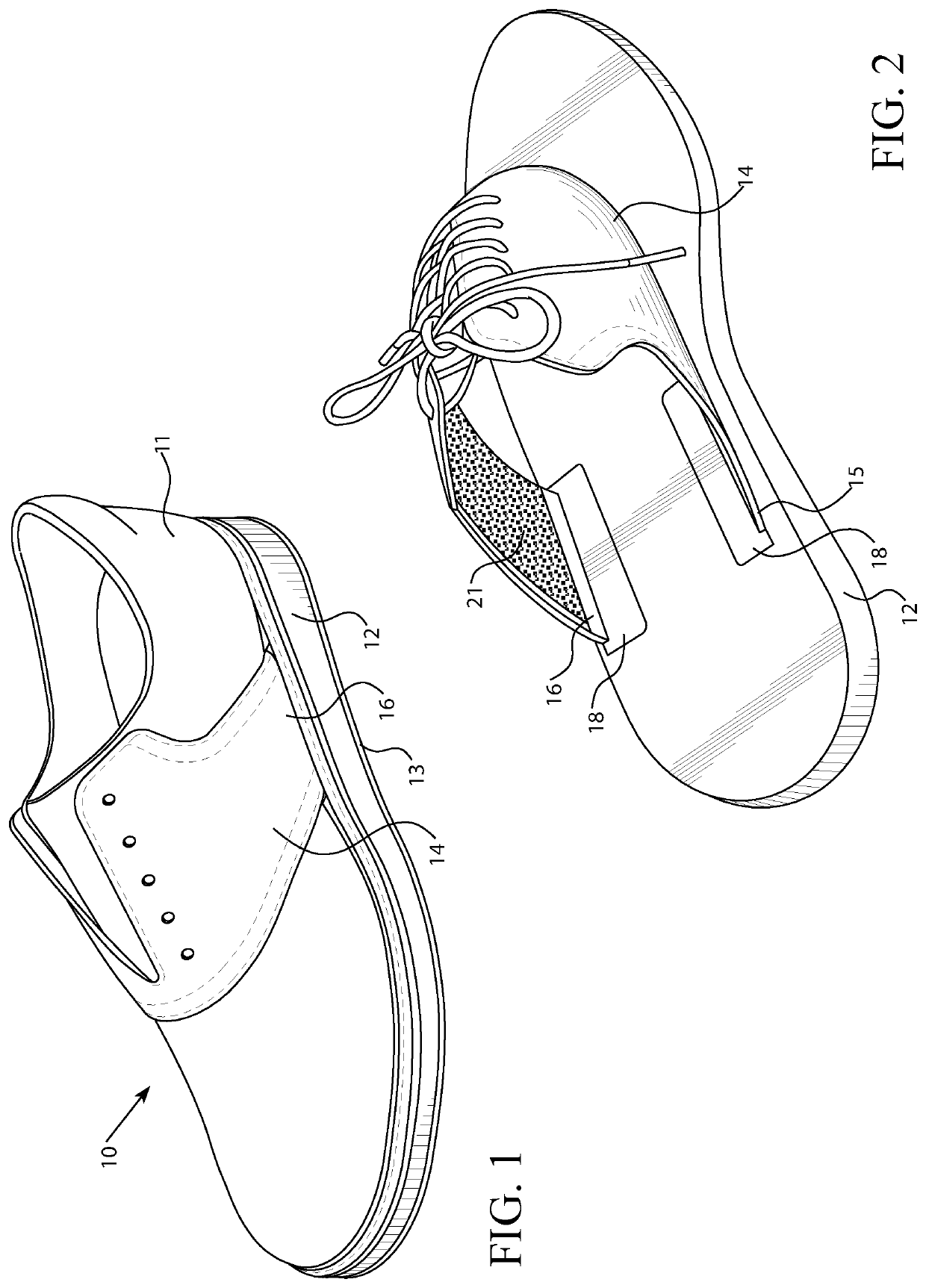

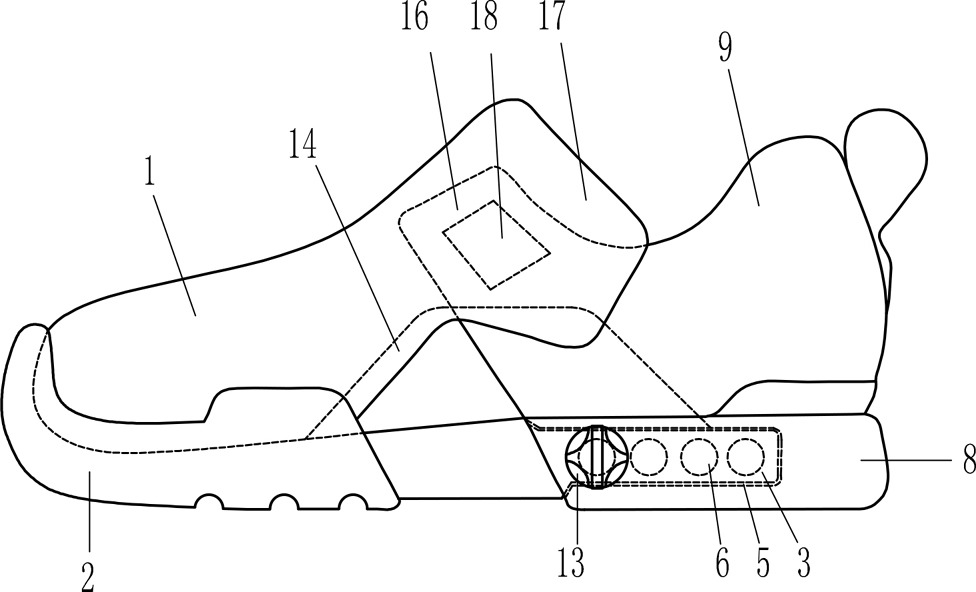

Footwear With One or More Removable and Interchangeable Panels

A shoe comprising an upper, a midsole coupled to the upper, a midsole insert comprising a channel, the midsole insert positioned proximal a junction between the upper and the midsole, and a shoe panel configured to detachably couple to the upper of the shoe. The midsole insert may further comprise a magnet within the channel that mates with a magnet of the shoe panel. Alternatively, the midsole insert channel may comprise one or more locking slots configured to receive one or more protrusions extending from the shoe panel. The shoe panel may be a midfoot or heel panel and may be detachably coupled to the upper by a hook and loop closure. The shoe may be a cupsole shoe with the midsole channel positioned proximal a junction between an inner surface of a vertical wall of the cupsole and the upper.

Owner:PRECEDO CAPITAL LLC

Method and apparatus for processing sole and heel surface skin lines

The invention is concerned with a dispose technology field of surface of shoes, special with a dispose method of the lines of surface to heel and sole and its equipment. Print lacquer and lines on PU wheel by printing wheel, press the heel or sole with priming on the PU wheel. Then PU wheel print the priming and lines on the surface of heel or sole to keep the same lines to really leathern of the surface of heel or sole. Adjust color with different priming with even color and unite the color of heel or sole, and the really leather cannot realize the effect of color. It has easy process, high produce efficiency and low cost.

Owner:孙志伟

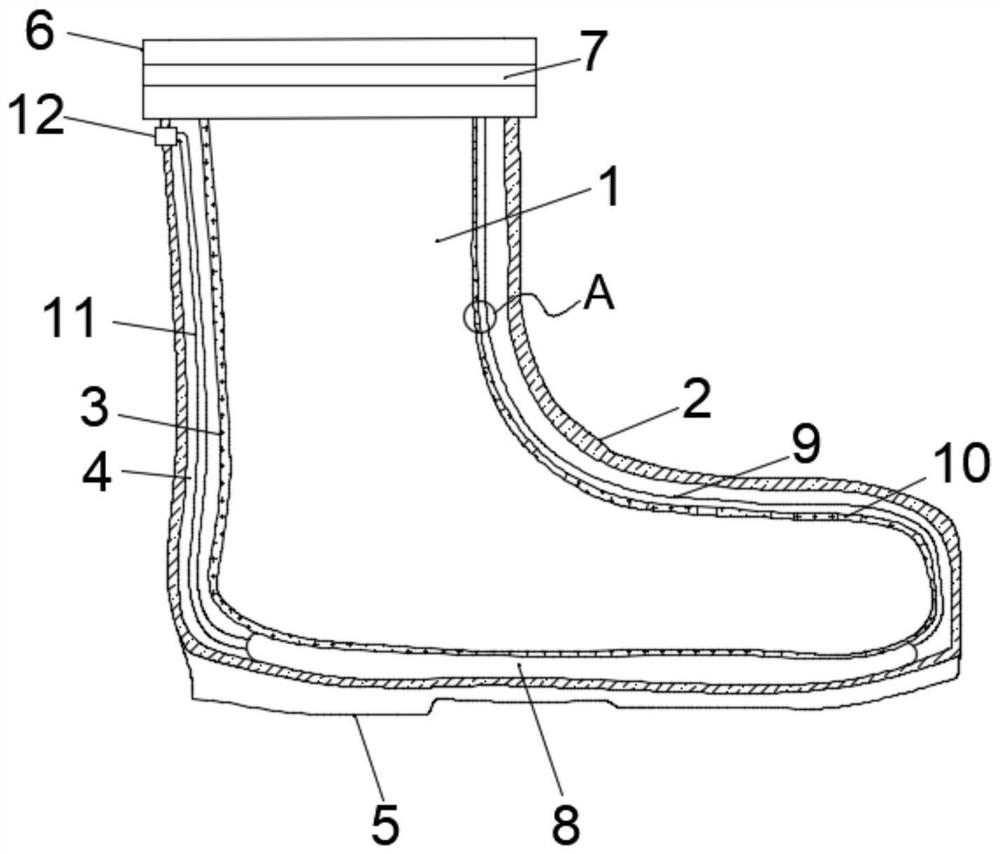

Anti-stuffy rain shoe capable of reducing sweating

The invention belongs to the field of rain shoes, and particularly discloses an anti-stuffy rain shoe capable of reducing sweating, which comprises a shoe body, a sole and a welt, a buffer airbag is fixed in an interlayer cavity at the bottom of the shoe body, two ends of the buffer airbag are respectively connected with a first air duct and a second air duct which are arranged in the interlayer cavity; and the first air duct is arranged on the front of the shoe body, and air outlets are formed in the side surface of the first air duct; the second air duct is arranged on the heel surface of the shoe body, and the upper end of the second air duct is connected with the valve head. The buffer air bag is arranged at the bottom of the shoe body, on one hand, the comfort of the foot is improved,on the other hand, the air circulation effect is formed through the contraction performance of the air bag, and the ventilation effect in the shoe body is guaranteed; the rebounding effect of the buffer air bag is enhanced through the multiple vesicles in the buffer air bag, and the overall ventilation capacity of the buffer air bag is enhanced through the telescopic capacity of the vesicles; thevalve deck and the drying device are detachably connected, drying agent particles in the shoe are convenient to replace, and the service life of the whole shoe body is guaranteed.

Owner:界首市旭升塑胶制品有限公司

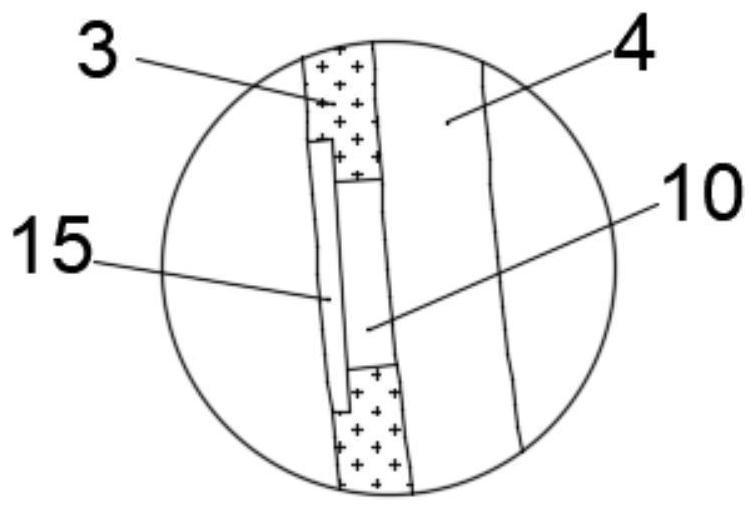

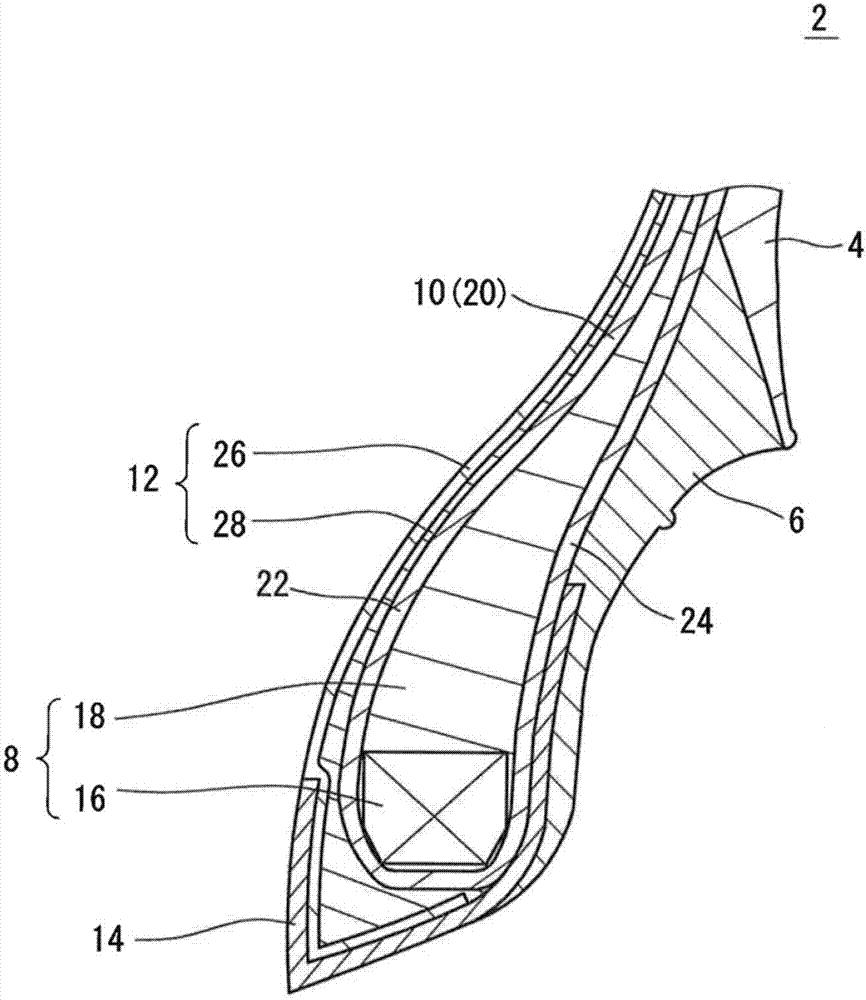

Golf club head

ActiveCN101879371AFavorable mass distributionImprove production efficiencyGolf clubsEngineeringGolf Ball

At least two golf clubs of a set, according to one or more aspects of the present invention, may include a strike face and a perimeter weighting element disposed behind the strike face. The perimeter weighting element may include an inner peripheral wall having a sole surface, a top surface, a heel surface, and a toe surface. A cavity, having a base surface, may be delimited by the inner peripheral wall and may include an insert disposed therein. The insert may comprise a primary element passively flexurally associated with one or more secondary elements and may be substantially identical for each head within the set. The primary element may be associated with the base surface and the at least one secondary element may be associated with at least one of the sole surface, the top surface, the toe surface, and the heel surface.

Owner:ROGER CLEVELAND GOLF

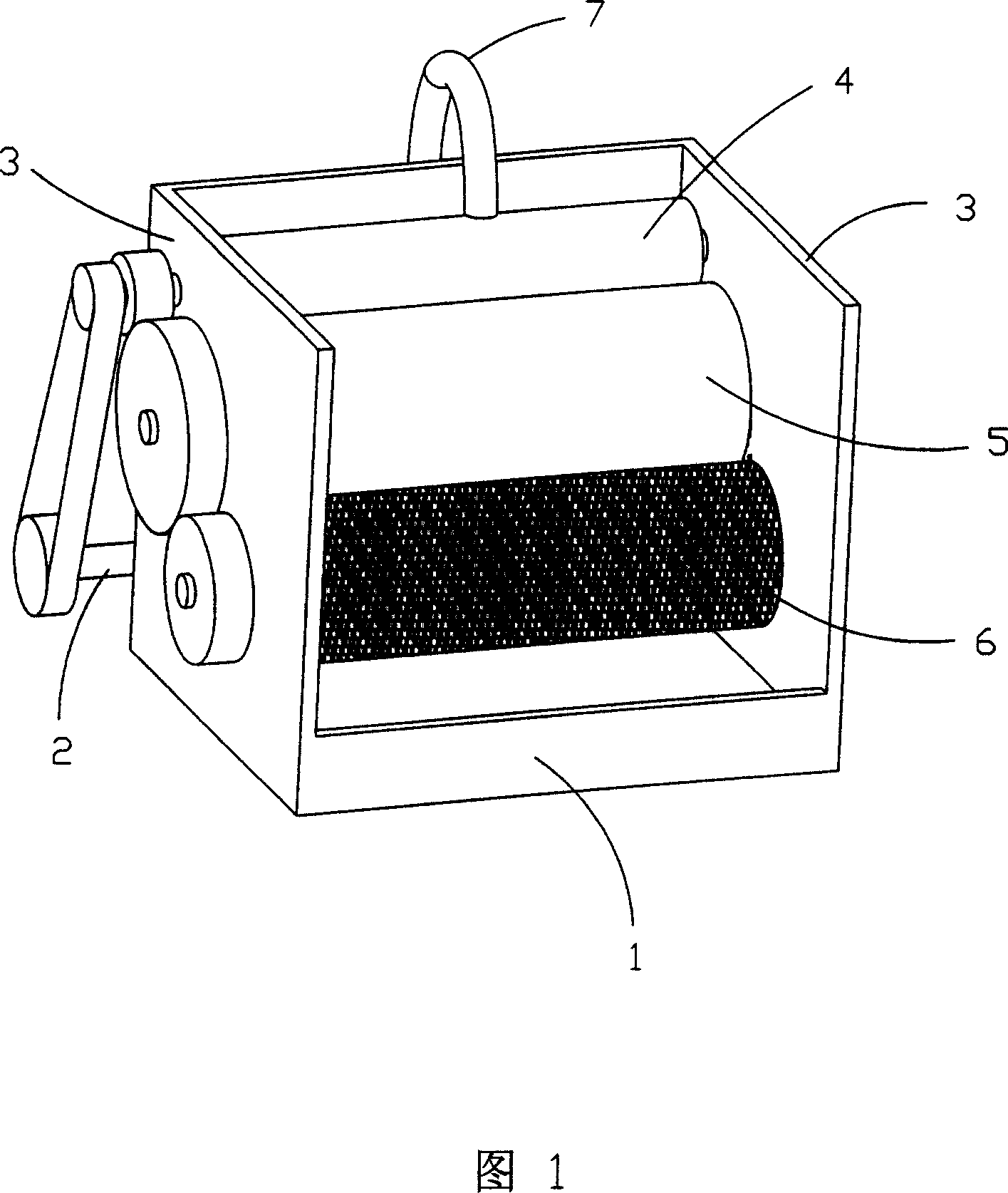

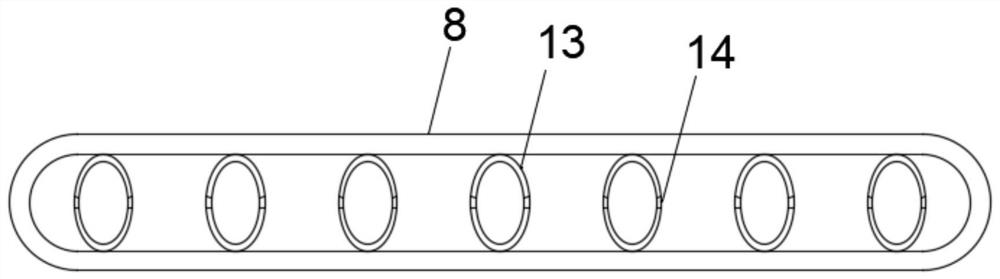

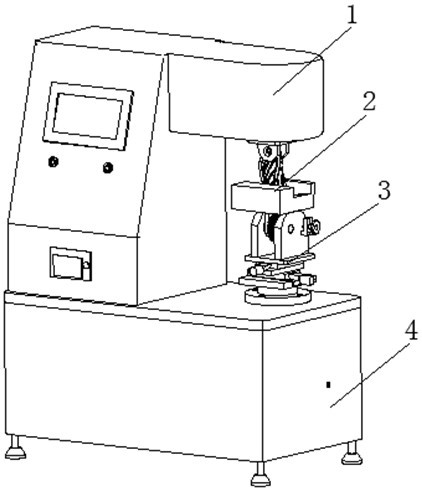

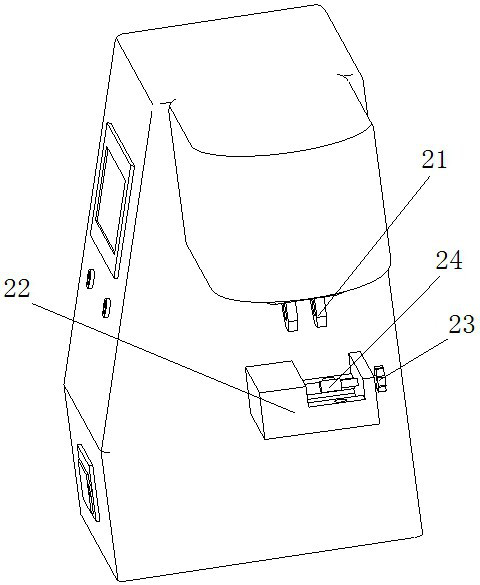

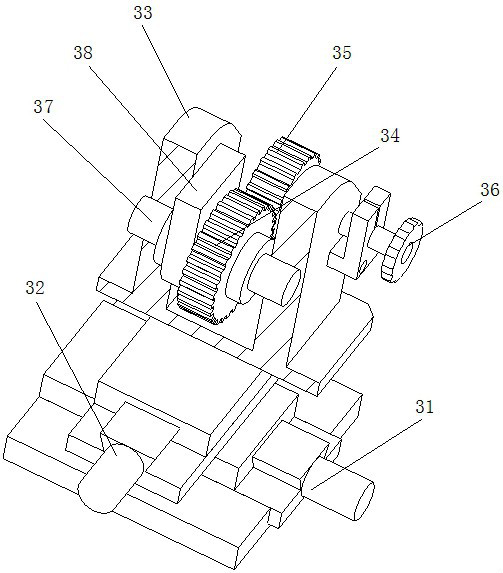

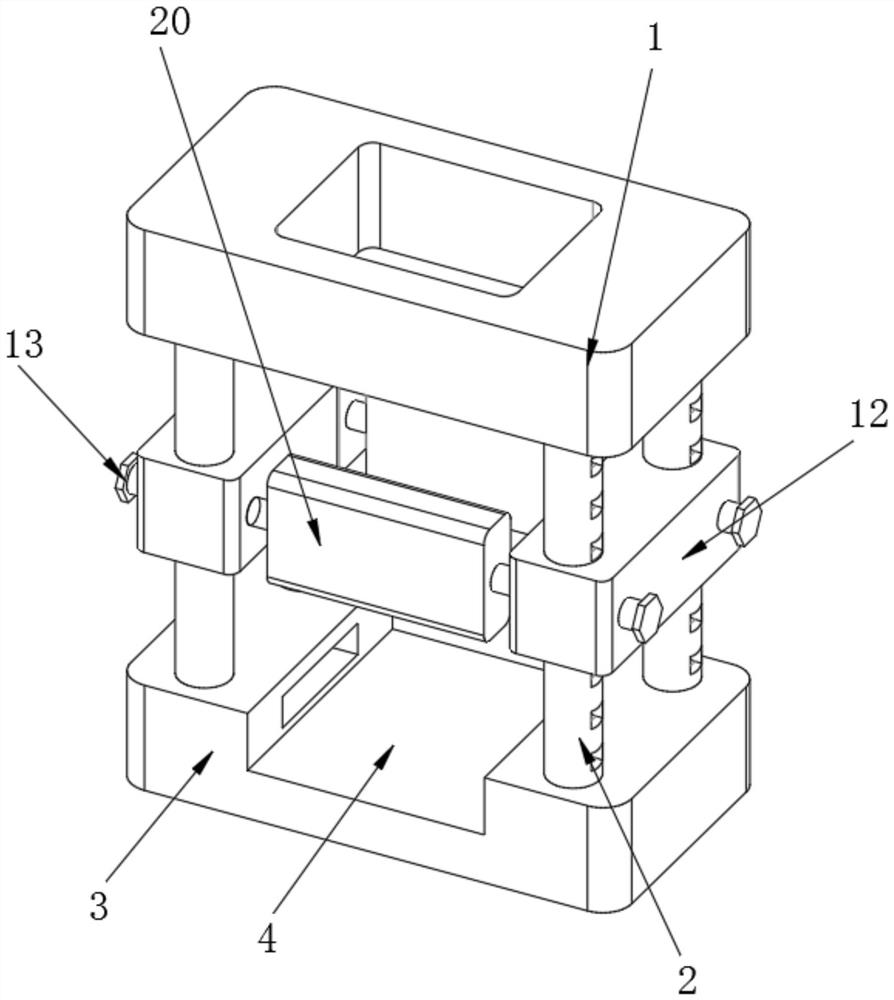

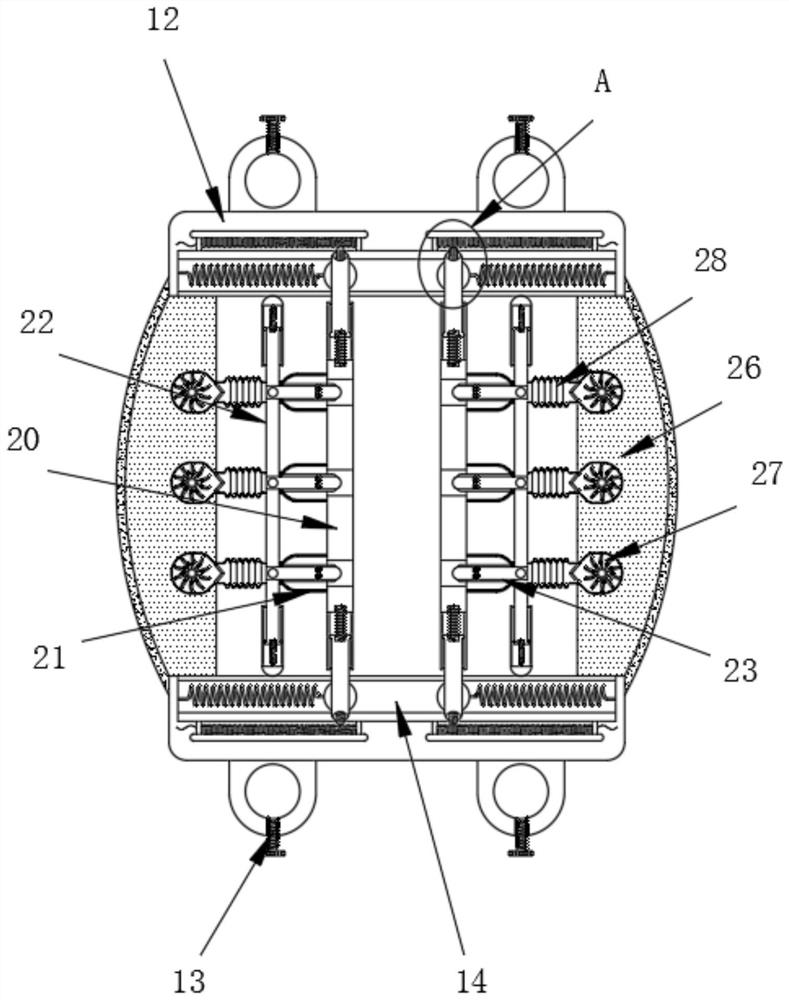

Heel surface material torsional strength testing machine

ActiveCN111929178AImprove versatilityAchieving conical rotationMaterial strength using steady torsional forcesClassical mechanicsStructural engineering

The invention discloses a heel surface material torsional strength testing machine. The invention belongs to the technical field of detection equipment. The machine comprises a shell, a clamping device, an adjusting device and a twisting device. The clamping device is arranged at the top of the adjusting device; the clamping device is used for clamping a heel and a toe cap of a to-be-tested shoe.The twisting device is arranged at the bottom of the adjusting device; the torsion device is used for providing power for shoe torsion. The adjusting device is used for adapting to shoes of differentshapes and sizes, and adjusting the positions of the shoes before the shoes are clamped by the clamping device; the adjusting device comprises a first micrometer sliding table, a second micrometer sliding table, an adjusting table, a first gear, a second gear and an adjusting handle, when the first micrometer sliding table and the second micrometer sliding table work, the adjusting table can be driven to move forwards, backwards, leftwards and rightwards at the same time, and position adjustment can be conveniently conducted according to different shapes and sizes of different shoes to be tested.

Owner:温州弘铭仪器有限公司

Pneumatic tire with specified bead portion profile

InactiveUS7438102B2Improve steering stabilityComfortable rideSpecial tyresInflatable tyresInternal pressureNormal load

A bead portion 4 of a pneumatic tire 1 includes a vertical rising surface portion Sw1 which is connected to a bead base surface Sb through an arc bead heel surface Sh, and a straight or convex arc flange receiving surface portion Sw2 which is diagonally extending from the rising surface portion Sw1 radially outward and axially outward of the tire. In a normal internal pressure in which no load is applied, the flange receiving surface portion Sw2 is not in contact with a flange surface Rf, and in a load state in which 50% or more of normal load is applied, the flange receiving surface portion Sw2 comes into contact with the flange surface Rf.

Owner:SUMITOMO RUBBER IND LTD

Method for shaping sole leather heel surface leather in shoe production

InactiveCN107373895AStable structureSolve issues that impact production qualityShoemaking devicesHeelsFiberBristle

The invention discloses a method for shaping the heel skin of bottom leather in the production of shoes, which is carried out on a flat knife machine; the milling of the edge of the heel skin uses a standard template, and the heel surface part is directly sanded on a grinder Grinding, and other milling around the excess need to fix the heel skin on the master model, and then carry out on the platform model milling bottom edge machine; firstly, put the paraffin block on the rotating bristle brush wheel or cloth wheel to make it stick Apply wax flakes, and then polish the heel leather. The frictional heat melts the wax flakes and penetrates into the leather fibers. If you need to increase the color of the leather, you can brush with soapy water and then polish it. The processing method utilizes a treatment process designed in consideration of the material particularity of the natural bottom leather, so that the structure of the heel area is stable, the quality of the surface and the interior meets the design requirements, and the quality of the shoes meets the requirements.

Owner:刘代学

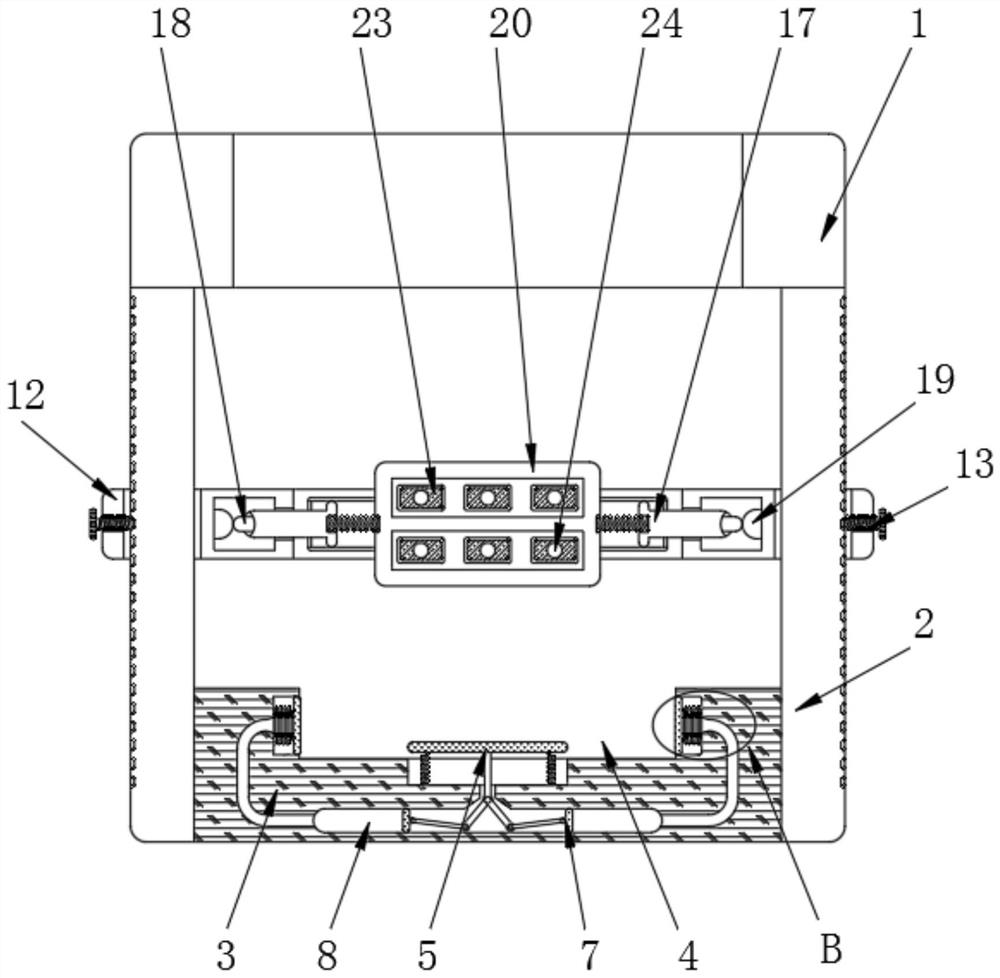

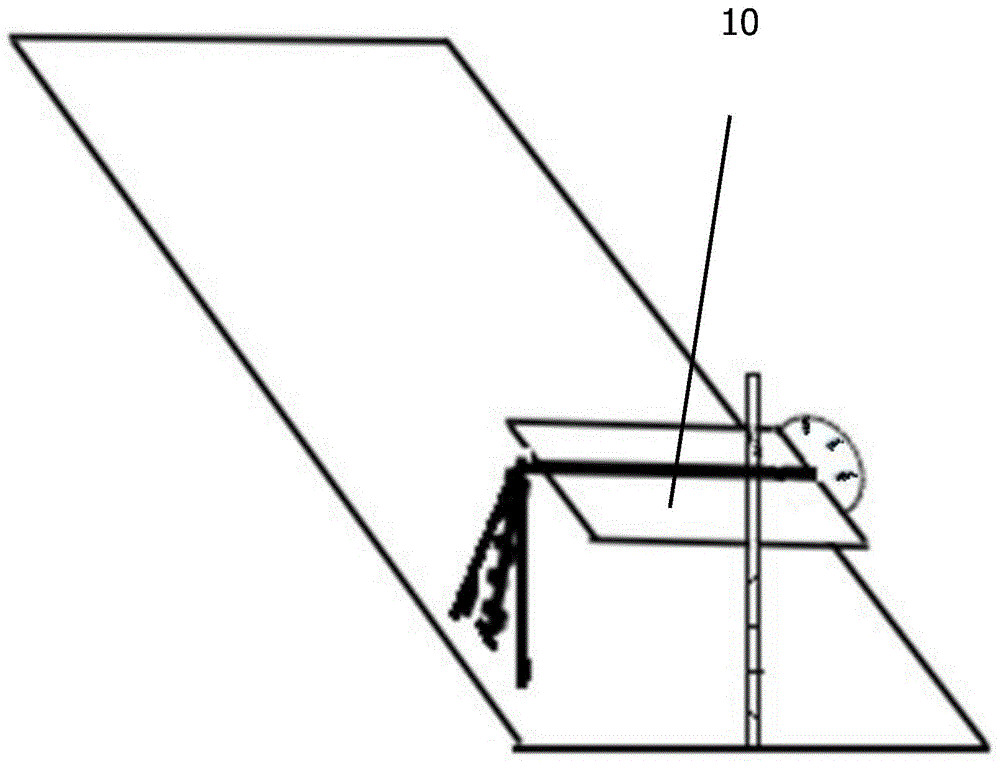

Equipment and method for shaping and processing bottom leather heel surface leather in shoe production

InactiveCN113974266AAvoid errorsAvoid damageShoemaking devicesGrinding machinesHeel surfaceSupport plane

The invention relates to the technical field of leather shoe manufacturing, and discloses equipment for shaping and processing bottom leather heel surface leather in shoe production. The equipment comprises a rack, a support frame is fixedly connected to the bottom of the rack, a base is fixedly connected to one end, far away from the rack, of the support frame, a placement groove is formed in the base, a pressing plate is slidably connected to the interior of the center of the placement groove, a movable connecting rod is rotatably connected to the bottom of the pressing plate, a blocking block is rotatably connected to the end, away from the pressing plate, of the movable connecting rod, and an air cavity is formed in the position, close to the outer side of the blocking block, of the base. The lower end of the heel surface leather is clamped through the clamping plate, and meanwhile, when the mounting frame slides towards the two sides, the air pump can be triggered to work, and the clamping block is pushed through a push plate to clamp the upper end of the heel surface leather, so that the effects that the upper end and the lower end of the heel surface leather can be clamped separately, and the heel surface leather is prevented from deviating during sanding to cause sanding errors are achieved.

Owner:赵先平

Split type adjustable shoe

The invention belongs to the field of shoes, and particularly relates to a split type adjustable shoe. The split type adjustable shoe comprises a shoe half sole, a shoe sole surface, a connecting block, a first fixing component, a second fixing component, a shoe sole heel and a heel surface, wherein the shoe sole surface is arranged at the shoe half sole; the heel surface is arranged at the heel of the sole; the connecting block is arranged on the side, which is close to the shoe sole heel, of the sole half sole; a connecting groove is formed in the side, which is close to the sole half sole,of the shoe sole heel; the connecting block is connected with the connecting groove in a matched mode; a plurality of first fixing holes are evenly formed in the connecting block; second fixing holesare formed in the shoe sole heel; the first fixing component and the second fixing component both penetrate through the first fixing holes and the second fixing holes; and the first fixing component is fixedly connected with the second fixing component. According to the invention, flexible assembly is achieved, the shoe size is adjusted according to the size of the foot, the shoe can be used for alonger time, the production problem of one-size-one-shoe production and manufacturing can be solved, and the production efficiency is improved.

Owner:域志有限公司

Heel nailing processing improved technology

The invention discloses a heel nailing processing improved technology. The heel nailing processing improved technology comprises the following steps of scribing heel opening lines, nailing outer heel strips, nailing heel inner leather, measuring to level, levelling and nailing heel surface leather. According to the heel nailing processing improved technology, the heel can be firmly fixed at the shoe sole due to strict control of a processing process, shaking or falling conditions during wearing are avoided, walking comfort and safety is guaranteed, and the inconvenient wearing problem in the existing heel nailing technology due to the fact that the technology control is not strict and accordingly the heel becomes loose and shakes or falls off is solved.

Owner:CHENGDU KAMEIDO SHOES

Contoured support shoe insole

An insole having a top sheet and a base layer with three pieces that include a base layer, a forefoot pad made of a clear TPR gel and a mid-foot to heel cushion made of a supersoft polyurethane. The midfoot / heel surface has a raised arch with criss-crossing longitudinal curvilinear indentations, a flattened midfoot area with a metatarsal midfoot tear-drop raised area, and a heel cup that surrounds the exterior back of the heel. A heel pod opening goes through the entirety of the thickness of base layer of the insole body and a heel pad is affixed to the bottom surface of the base layer being made of a clear TPR gel or blown EVA. There is also a supersoft heel dome and a metatarsal raised dome on the top (foot contact) surface of the insole which would be directly above the heel pod and the metatarsal midfoot area, respectively.

Owner:IMPLUS FOOTCARE

Nailing method based on adopting blind nailing for shoe heel upper leather

InactiveCN104223585AExtended service lifeSolve the problem that the service life is affectedHeelsTop-piecesCutting nailsEngineering

The invention discloses a nailing method based on adopting blind nailing for shoe heel upper leather. The method comprise the following steps of adopting a hair brush to uniformly brush mucilage glue on the surface of the shoe heel upper leather and the surface of a shoe heel palm side, and drying the surfaces brushed with the mucilage glue; sequentially nailing a round nail with the length of 16mm into a heel body at the part, which is 6-7mm far away from the heel body side; using a pair of counterpart pliers to slantways cut off the nail rod part of the round nail, which is exposed out of the heel body, so that the length of the nail rod remaining on the surface of the heel body is 2 / 3 of the thickness of the shoe heel upper leather; placing the shoe heel upper leather above the cut nail rod, aligning at the position, hammering the heel surface, and puncturing the oblique angle-shaped nail rod into the heel surface, so that the heel surface and the heel body are nailed tightly, flatly, evenly and firmly. According to the nailing method, the round nail is adopted to be nailed in a shoe heel completely, so that the nail cannot be contacted with the ground when shoes are worn, the combination of the shoe heel upper leather is more stable, the service life of the shoes is longer, and the problem that the service life of the shoes is affected since the internal structure is unstable when the shoe heel upper leather is nailed according to the existing nailing method is solved.

Owner:SICHUAN KAMEIDI SHOES IND

Special improvement method for assembling of full-breast heel in flat-heel shoe

InactiveCN104188273AFirmly assembledImprove assembly efficiencyNailingShoe gluingEngineeringImprovement methods

The invention discloses a special improvement method for assembling of a full-breast heel in a flat-heel shoe. The heel adheres to an outsole, and a combined outsole is formed; aligning, lasting and shaping are carried out; round nails are knocked into a heel body, the distance between every two adjacent round nails ranges from 8 mm to 10 mm, the nail rod portions, exposed outside the heel body, of the round nails are cut off through opposite-jaw pliers, the lengths of nail rods reserved on the surface of the heel body are two thirds of the thickness of a wrapper of the heel, the wrapper of the heel is placed on the cut-off nail rods, the heel surface is hammered, the bevel nail rods are stuck into the heel surface, and the heel surface adheres to the heel body tightly in a nailed mode; heel nails are knocked in, a wood screw is screwed into a hook center fixing hole, two wood screws are screwed into two sides of a hook center, the two wood screws on the two sides of the hook center and the wood screw in the hook center fixing hole form a triangle, the wood screws are screwed in the heel after two thirds of each wood screw is screwed in, and caps of all the heel nails are flush with an insole surface. According to the method, an assembling process of the full-breast heel in the flat-heel shoe is improved, so that assembling efficiency of the full-breast heel is higher, assembling is more stable, balance of the full-breast heel is achieved easily, and people wear shoes more comfortably and safely.

Owner:CHENGDU CAMEIDO SHOES

Method capable of improving grinding efficiency of finished shoe

InactiveCN107373907AQuality improvementComfortable to wearShoemaking devicesMilling cutterEngineering

The invention discloses a method capable of improving the grinding efficiency of finished shoes, comprising the following steps: opening the grinding machine, installing a milling cutter at an angle of 60° to the horizontal plane on the grinding machine, gradually approaching the milling cutter with the finished shoes, and using the milling cutter to Mill the bottom edge, chassis, heel body and heel edge of the shoe to make the surface smooth and the mouth is clear; use No. 0 or No. 1 emery cloth to go back and forth on the bottom edge, chassis, heel body and heel edge of the milled shoe Friction, when processing the edge of the outsole, brush part of the water as lubrication. When processing the chassis, first process the forefoot, and then process the waist; remove the edge of the edge of the sanded shoe that connects to the wire rod, and the heel surface At the junction with the shoe root leather, after the bottom tongue of the rolled root is glued to the heel surface, it is necessary to wash off the amount of 2 to 4 mm of the bottom tongue. After completing the above operation steps, the finished shoes that meet the requirements can be obtained. . The method can grind the finished shoes to meet the design requirements, so that the quality of the shoes can be improved.

Owner:刘代学

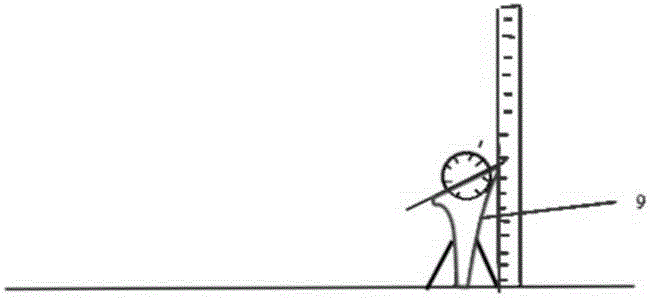

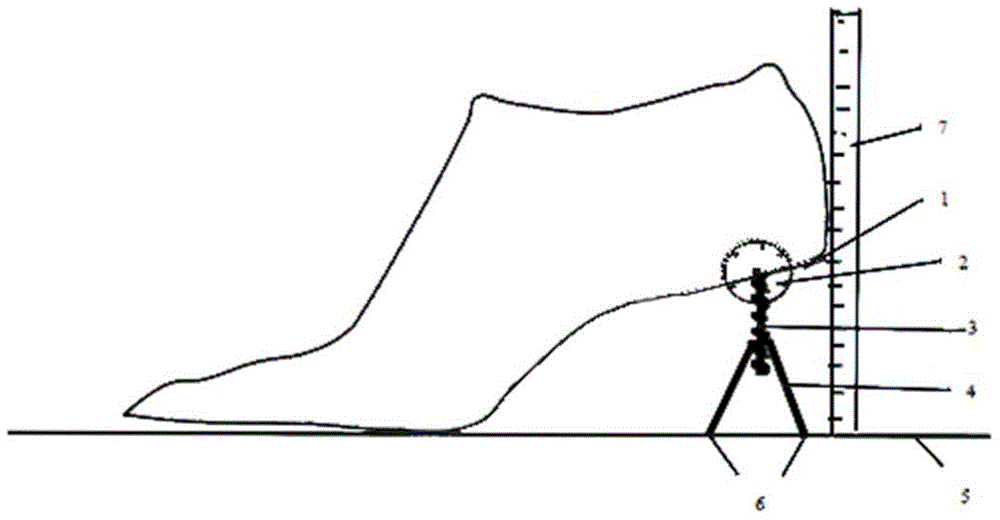

Heel surface inclination angle measuring instrument

InactiveCN104872928AAccurate measurement of inclinationAccurate height measurementFoot measurement devicesPhysicsHeel surface

The invention discloses a heel surface inclination angle measuring instrument and belongs to the technical field of measuring instruments. The heel surface inclination angle measuring instrument comprises a heel surface inclination angle measuring plate, an inclination angle indicator, a height adjusting rod, an adjustable bracket, a bottom plate, a rear heel height indicator and an extension fixed shaft, wherein the adjustable bracket is fixedly connected to the side edge of one end of the bottom plate; the height adjusting rod is vertical to the plate surface of the bottom plate and is screwed to the adjustable bracket; one end of the extension fixed shaft is connected to the top end of the height adjusting rod and is parallel to the plate surface of the bottom plate; the inclination angle indicator is fixedly arranged at the other end of the extension fixed shaft; the heel surface inclination angle measuring plate is connected to a rod body of the extension fixed shaft in a manner of rotating around the extension fixed shaft; the rear heel height indicator is arranged at the edge of one end of the bottom plate. The heel surface inclination angle measuring instrument can assist a designer to quickly and accurately measure the inclination and the height of the inclination surface of a high heel according to scientific parameters during the design of high-heeled shoes, the designed high-heeled shoes can more accord with the human biology particularly, and the wearing comfort is improved.

Owner:ZHEJIANG IND & TRADE VACATIONAL COLLEGE

Pneumatic Tire

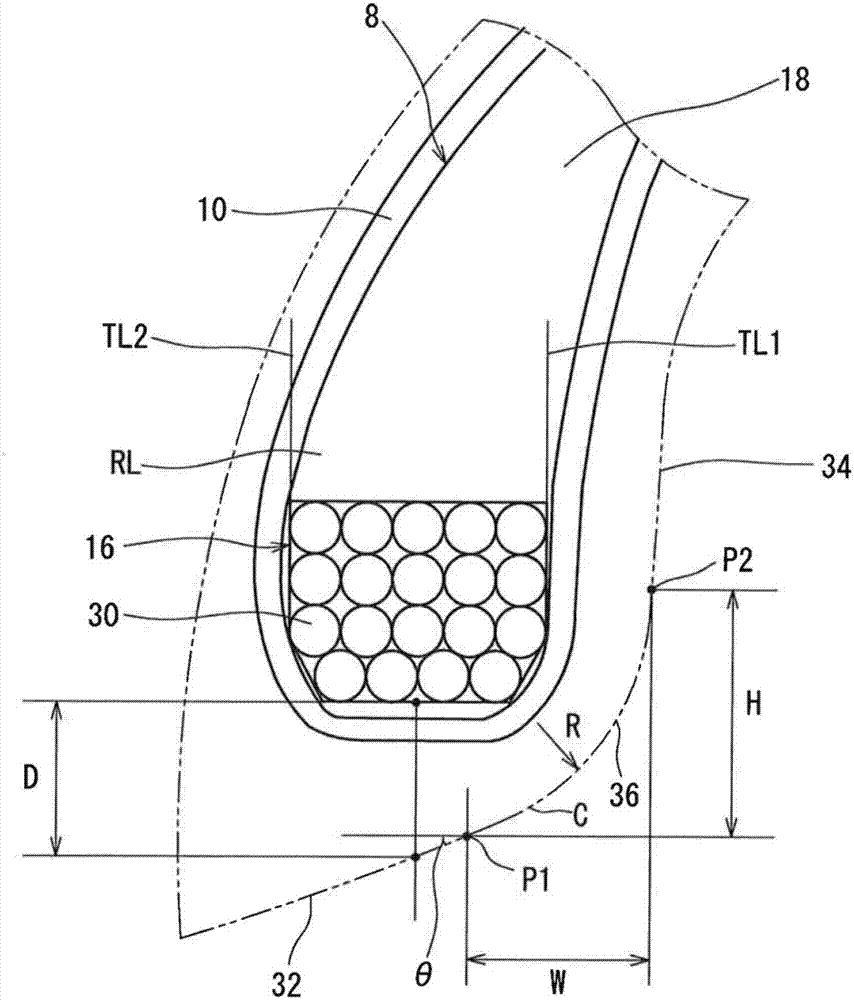

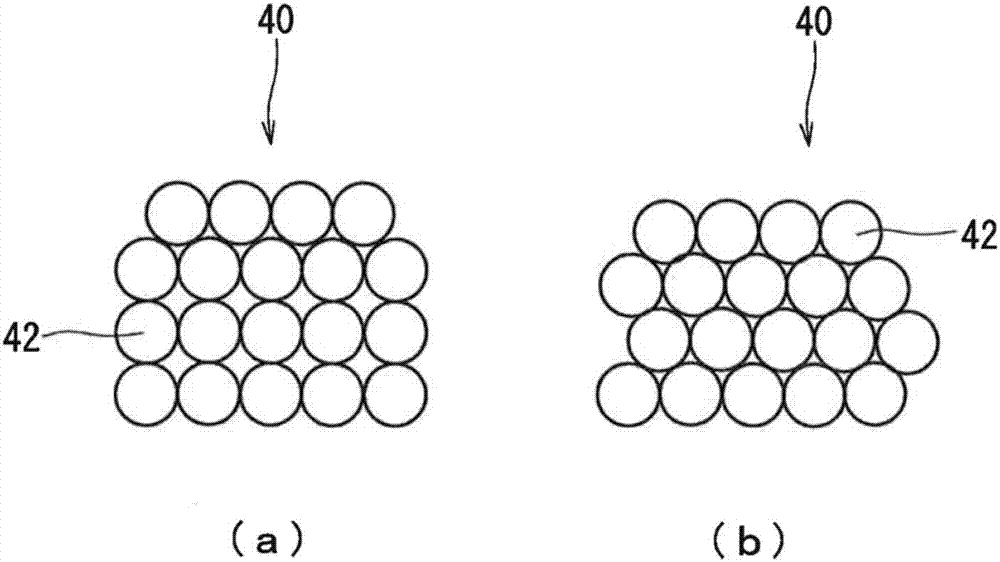

In a tire (2), on a cross-section, three or more rows in each of which cross-sections (30) of a wire are aligned almost in the axial direction, are layered in the radial direction. The cross-sections (30) of the wire in a first row disposed on an innermost side in the radial direction and the cross-sections (30) of the wire in a second row layered outward of the first row are staggered. On a cross-section obtained by the tire (2) being cut at a plane perpendicular to the circumferential direction, an outline of a heel surface (36) of a bead (8) portion has an arc C that projects toward an outside of the bead (8) portion. A radius R of curvature of the arc C is greater than or equal to 8 mm and not greater than 12 mm.

Owner:SUMITOMO RUBBER IND LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com