Efficient crushing equipment for medical waste

A high-efficiency grinding and medical waste technology, applied in grain processing and other directions, can solve problems such as time-consuming, operator infection, and operator injury.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

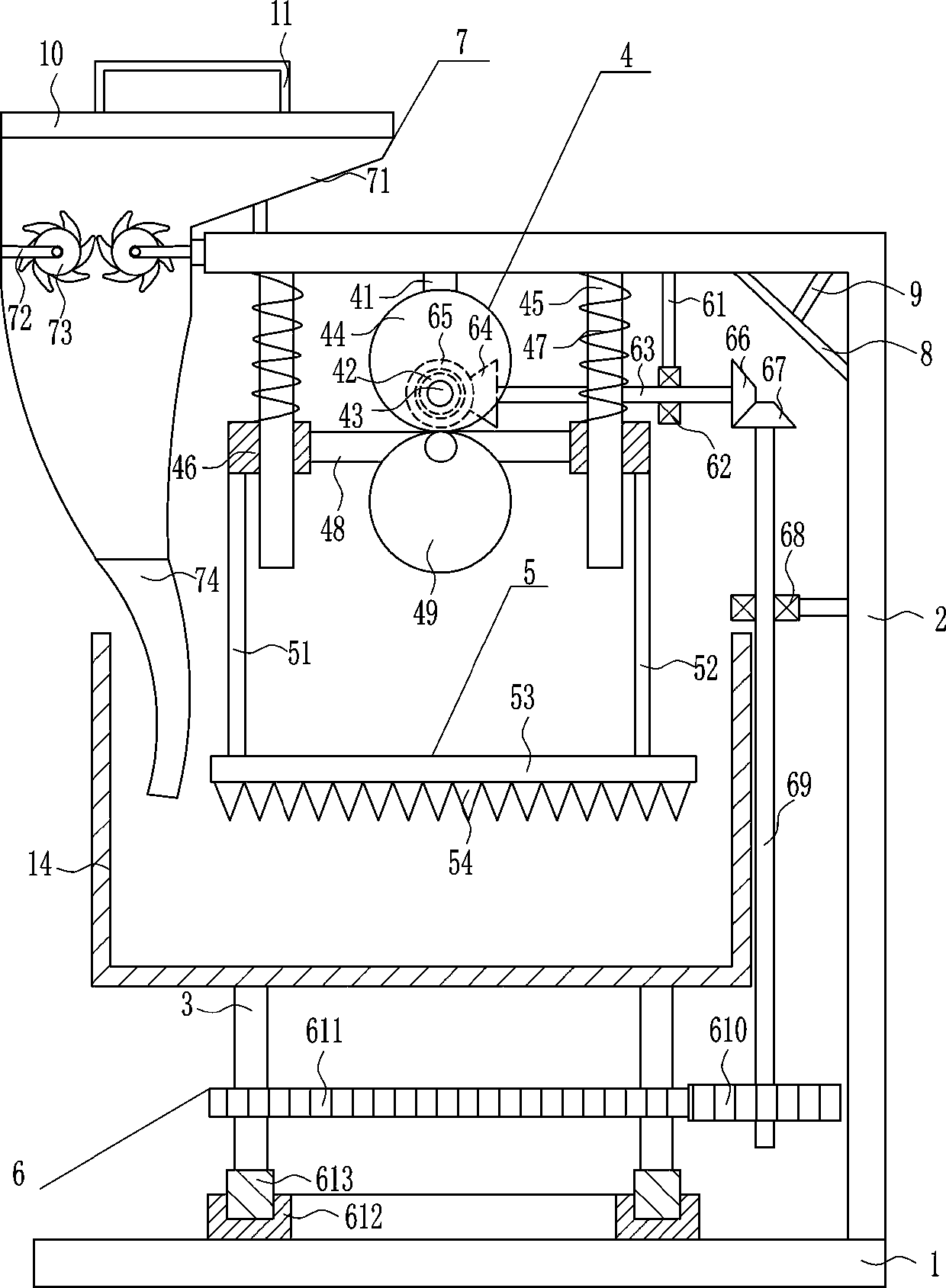

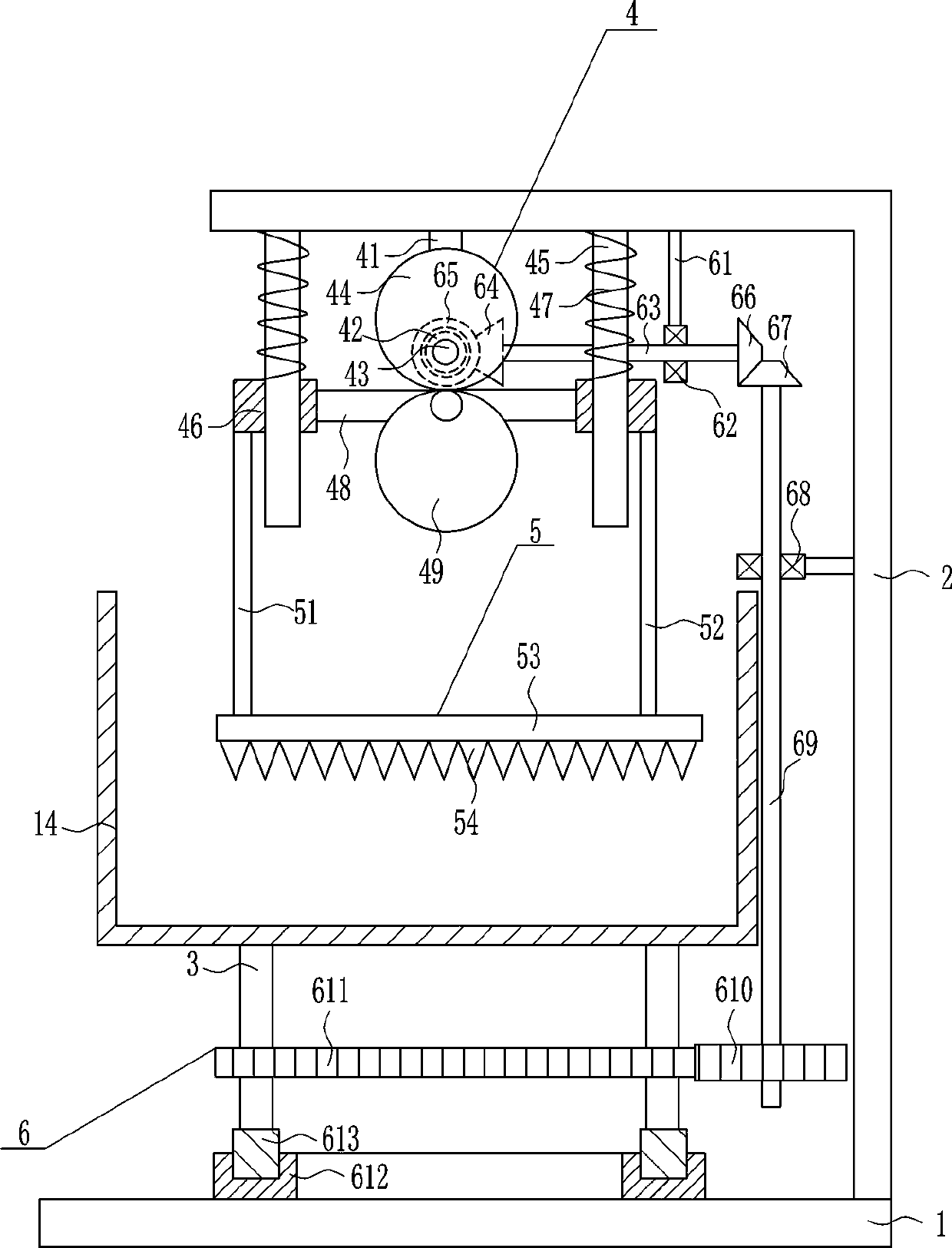

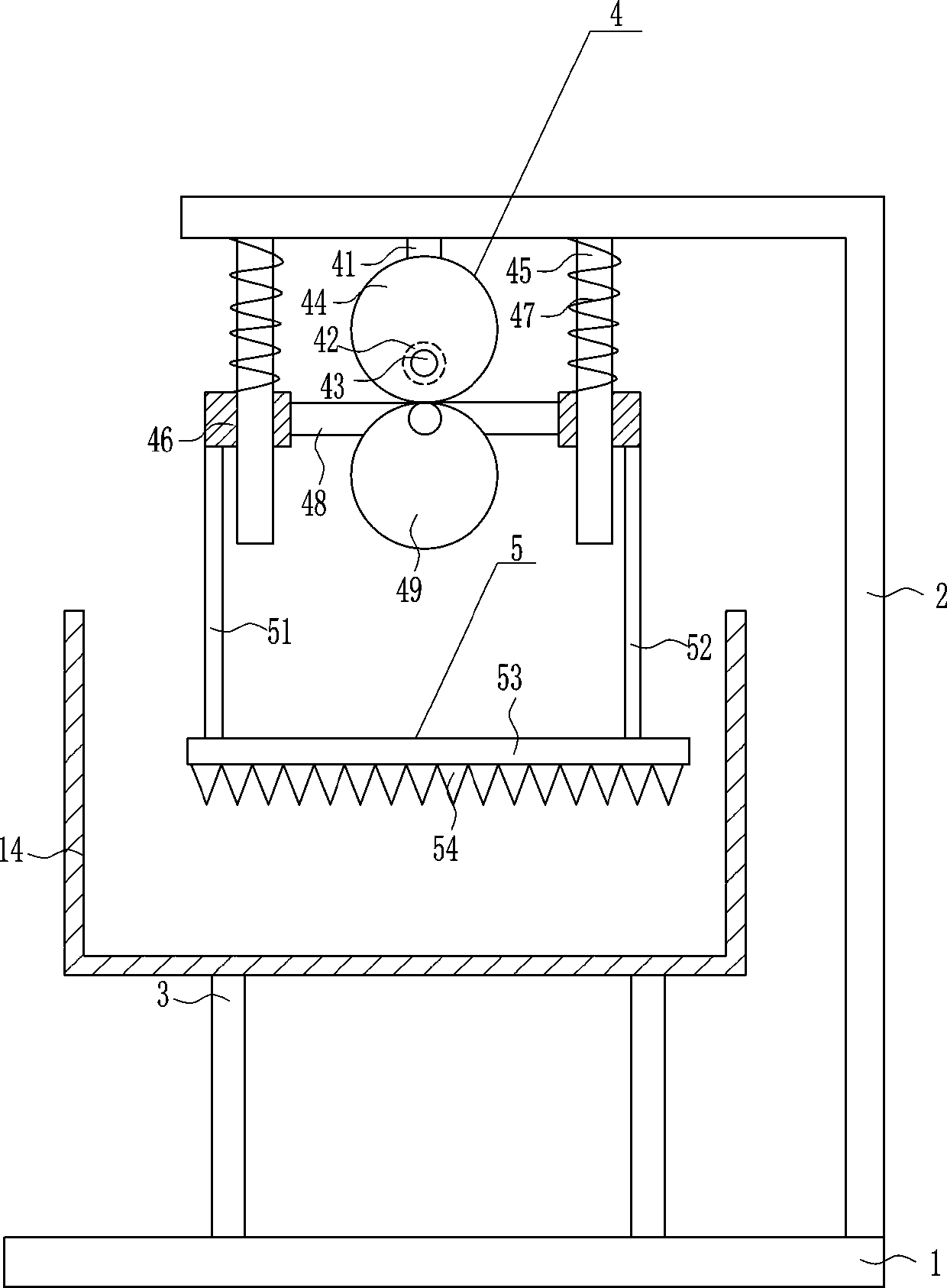

[0035] A high-efficiency crushing equipment for medical waste, such as Figure 1-5 As shown, it includes a bottom plate 1, a 7-type plate 2, a support rod 3, a driving device 4, a crushing device 5 and a crushing frame 14. The top of the bottom plate 1 is symmetrically installed with a support rod 3, and the top of the support rod 3 is equipped with a crushing frame 14. , the right side of the top of the base plate 1 is equipped with a 7-type plate 2, and the middle of the bottom of the 7-type plate 2 is provided with a driving device 4, and the driving part of the driving device 4 is provided with a crushing device 5.

Embodiment 2

[0037] A high-efficiency crushing equipment for medical waste, such as Figure 1-5 As shown, it includes a bottom plate 1, a 7-type plate 2, a support rod 3, a driving device 4, a crushing device 5 and a crushing frame 14. The top of the bottom plate 1 is symmetrically installed with a support rod 3, and the top of the support rod 3 is equipped with a crushing frame 14. , the right side of the top of the base plate 1 is equipped with a 7-type plate 2, and the middle of the bottom of the 7-type plate 2 is provided with a driving device 4, and the driving part of the driving device 4 is provided with a crushing device 5.

[0038] The driving device 4 includes a mounting plate 41, a first motor 42, a first rotating shaft 43, a first gear 44, a slide bar 45, a sliding sleeve 46, a first spring 47, a first cross bar 48 and a second gear 49, 7 type A mounting plate 41 is vertically installed in the middle of the bottom of the plate 2, a first motor 42 is installed on the front side ...

Embodiment 3

[0040] A high-efficiency crushing equipment for medical waste, such as Figure 1-5 As shown, it includes a bottom plate 1, a 7-type plate 2, a support rod 3, a driving device 4, a crushing device 5 and a crushing frame 14. The top of the bottom plate 1 is symmetrically installed with a support rod 3, and the top of the support rod 3 is equipped with a crushing frame 14. , the right side of the top of the base plate 1 is equipped with a 7-type plate 2, and the middle of the bottom of the 7-type plate 2 is provided with a driving device 4, and the driving part of the driving device 4 is provided with a crushing device 5.

[0041] The driving device 4 includes a mounting plate 41, a first motor 42, a first rotating shaft 43, a first gear 44, a slide bar 45, a sliding sleeve 46, a first spring 47, a first cross bar 48 and a second gear 49, 7 type A mounting plate 41 is vertically installed in the middle of the bottom of the plate 2, a first motor 42 is installed on the front side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com