Universal polisher

A technology for grinding machines and grinding parts, which is applied in the direction of grinding machines, grinding/polishing equipment, metal processing equipment, etc., and can solve problems such as inability to grind and inconvenient movement of the grinding machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the following embodiments are combined with the accompanying drawings to elaborate on the present invention.

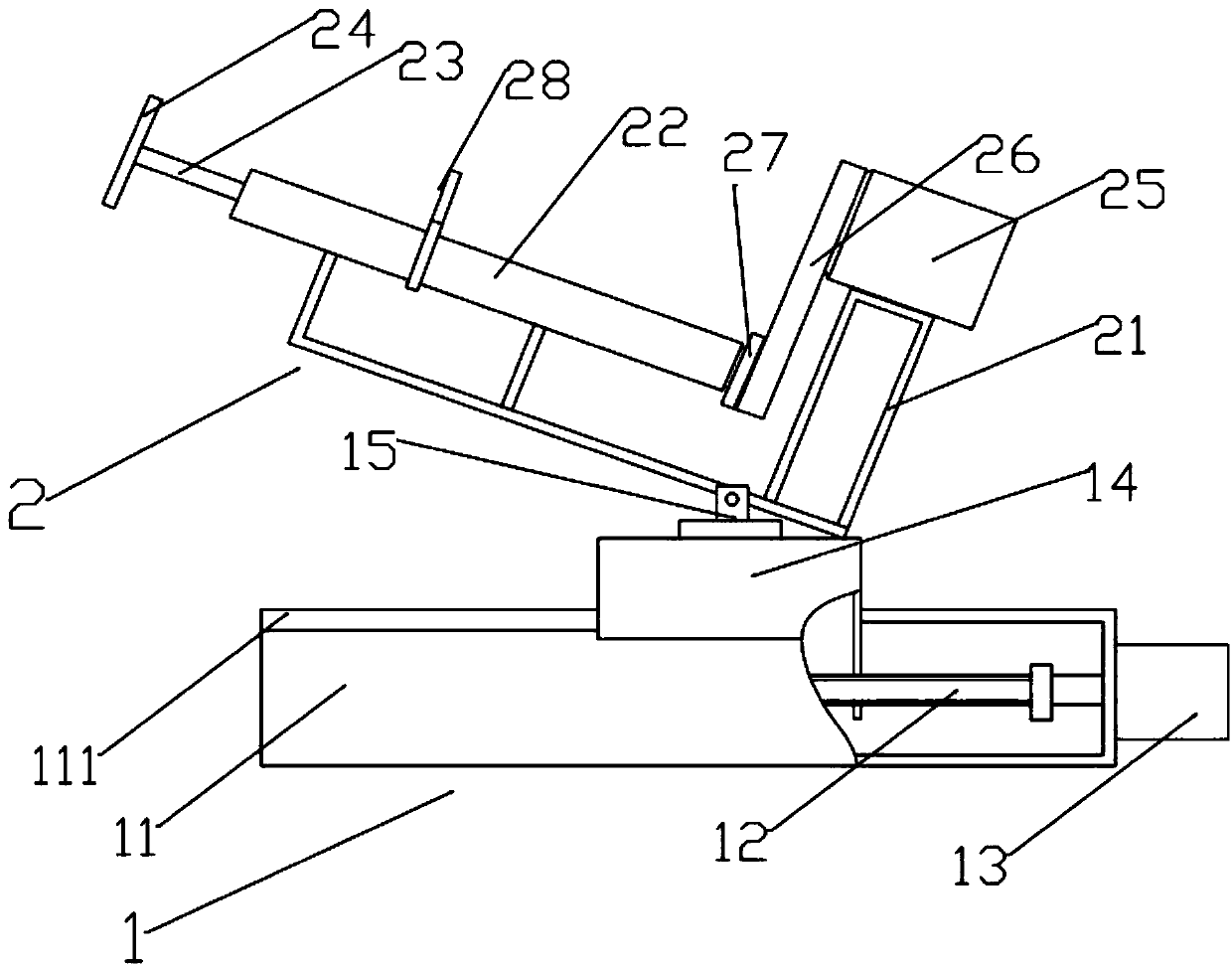

[0018] figure 1 It is a schematic structural diagram of the universal grinding machine of the present invention, please combine figure 1 mentioned. A preferred universal grinding machine is shown, including a grinding part 2 and a horizontal position adjustment part 1, wherein the grinding part 2 is movably arranged on the horizontal position adjustment part 1 and adjusted with the horizontal position The part 1 is hinged so that the grinding part 2 rotates around the hinge point, and the horizontal position adjusting part 1 drives the grinding machine to rotate and move horizontally. The horizontal position adjusting part 1 is provided with a turntable 15 , and the turntable 15 is hinged to the grinding part 2 .

[0019] In the pr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap