Multi-Layer PZT Microactuator Having A Poled But Inactive PZT Constraining Layer

A micro-actuator, electrode technology, applied in the configuration/installation of the recording head, the installation/connection of the transducing head relative to the arm part, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

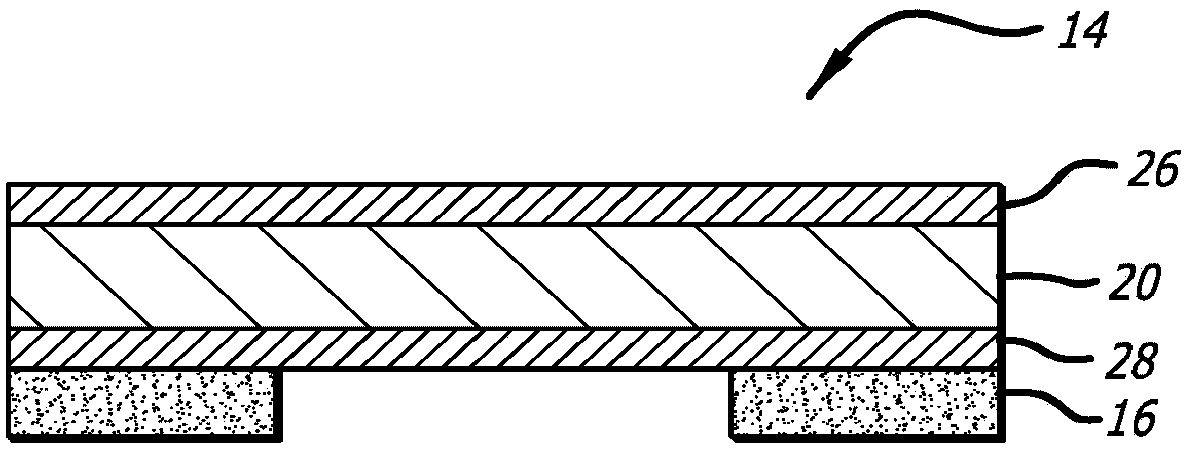

[0074] Figure 7 is a side cross-sectional view of a PZT microactuator assembly 114 with a constraining layer 130 incorporated thereon, in accordance with one embodiment of the present invention. Consistent with the orientation shown in the figures, the side of the PZT that is bonded to the suspension will be referred to as the bottom side 129 of the PZT 114, and the side of the PZT away from the side from which the PZT is bonded will be referred to as the bottom side 129 of the PZT 114. 127 for the top side. According to the present invention, one or more constraining layers or constraining elements 130 are bonded to the top side 127 of the microactuator PZT element 120 . The constraining layer 130 preferably comprises a rigid and elastic material, such as stainless steel, and is preferably bonded directly to the top surface 127 of the PZT element 120 including its top electrode 126, or the SST material itself can be used as the top electrode, thus eliminating the need for a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com