Long-distance and constant-temperature conveying pipe of fire retardant for plastic granulating

A flame retardant and conveying pipe technology, which is applied in the field of long-distance constant temperature conveying pipes for flame retardants for plastic granulation, can solve the problems such as the inability to guarantee the constant temperature transmission of the flame retardants, the inability to meet the requirements of the amount of the flame retardants, etc. Market prospect, simple structure, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The specific implementation of the present invention will be further elaborated below in conjunction with the examples.

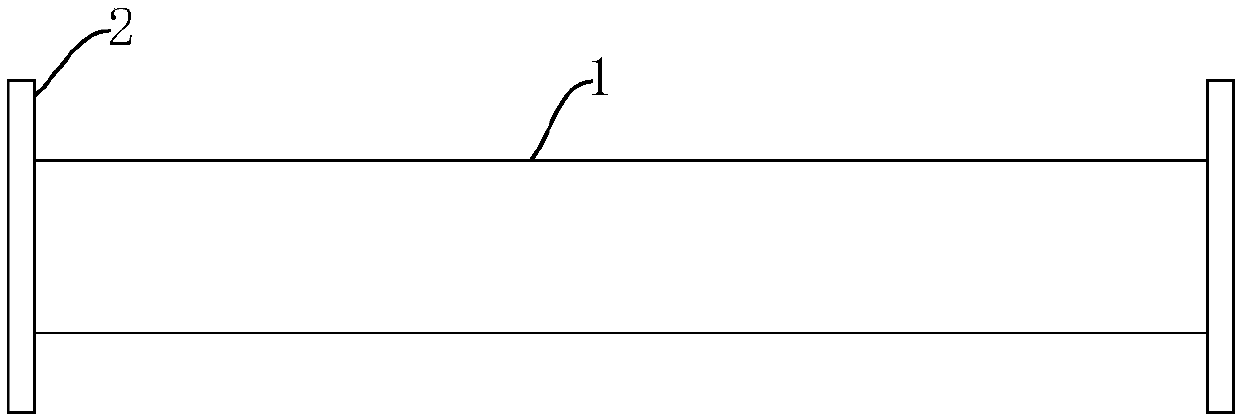

[0013] Such as Figure 1 to Figure 2 As shown, a flame retardant long-distance constant temperature delivery pipe for plastic granulation provided by this embodiment includes a pipe body 1, flanges 2 are provided at both ends of the pipe body 1, and the pipe body is made 1 The installation with the reactor is more convenient, just tighten the bolts.

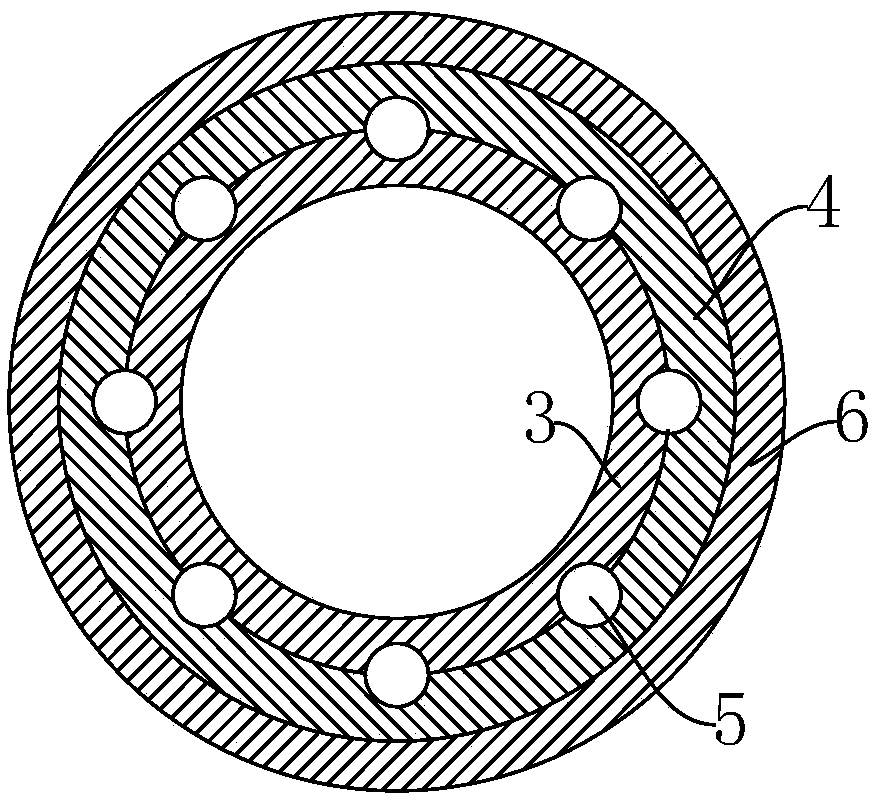

[0014] The tube body 1 includes an inner tube 3 and an outer tube 4 sleeved outside the inner tube. The outer wall of the inner tube 3 is provided with a plurality of A grooves along the axial direction of the inner tube, and the inner wall of the outer tube 4 is arranged along the axial direction of the outer tube. There are a plurality of B tanks corresponding to the A tanks, the A tanks and the B tanks cooperate to form a circulation channel 5 for the circulation of the heating medium, and a constan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com