Electroplating clamp for rubber plugs and electroplating method adopting same

A technology of electroplating fixtures and rubber plugs, which is applied in the electrolysis process and electrolytic components, etc. It can solve the problems affecting the quality of rubber plugs, injection molding rubber plugs, and the loss of electroplating layer wear and tear, and achieve the effect of strengthening the thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

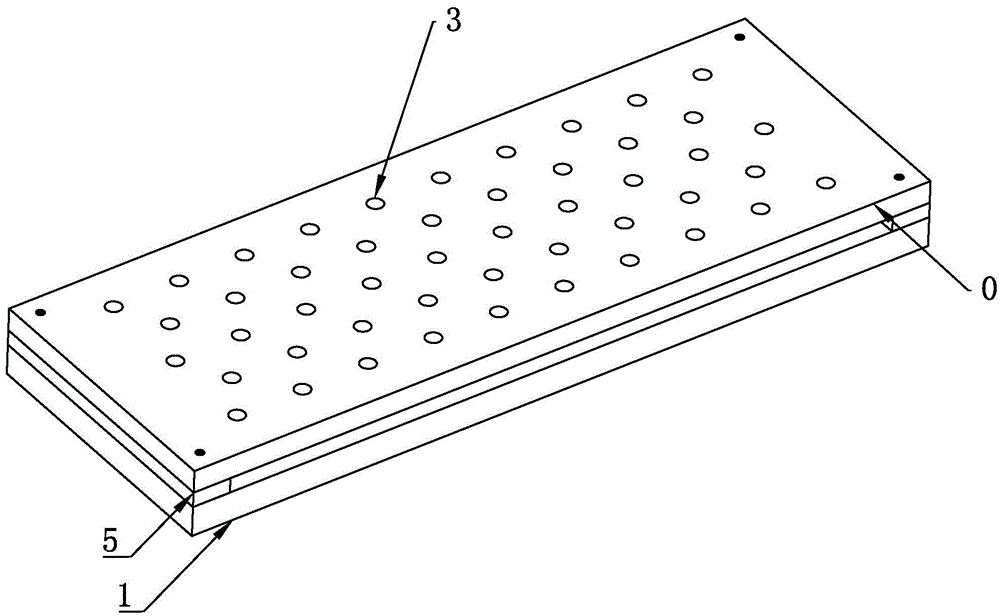

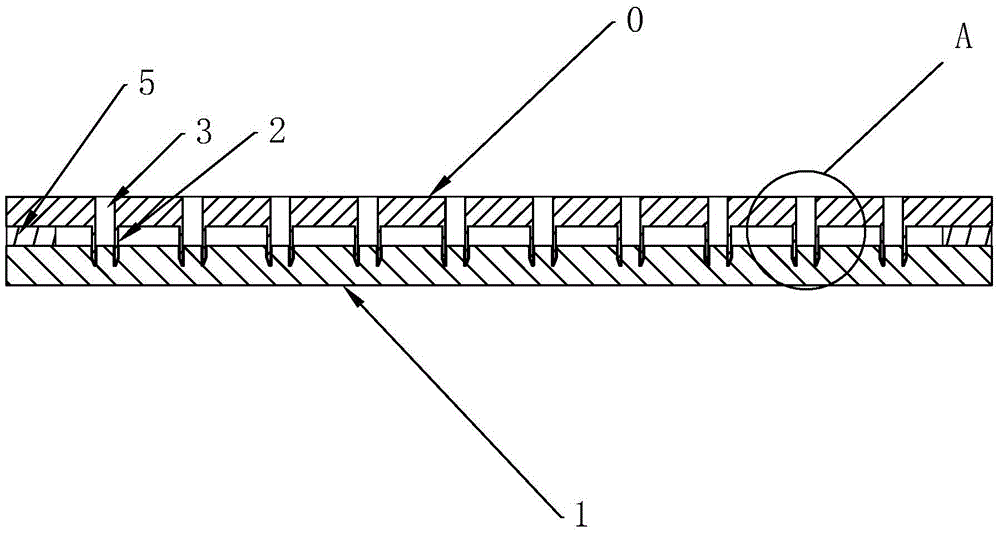

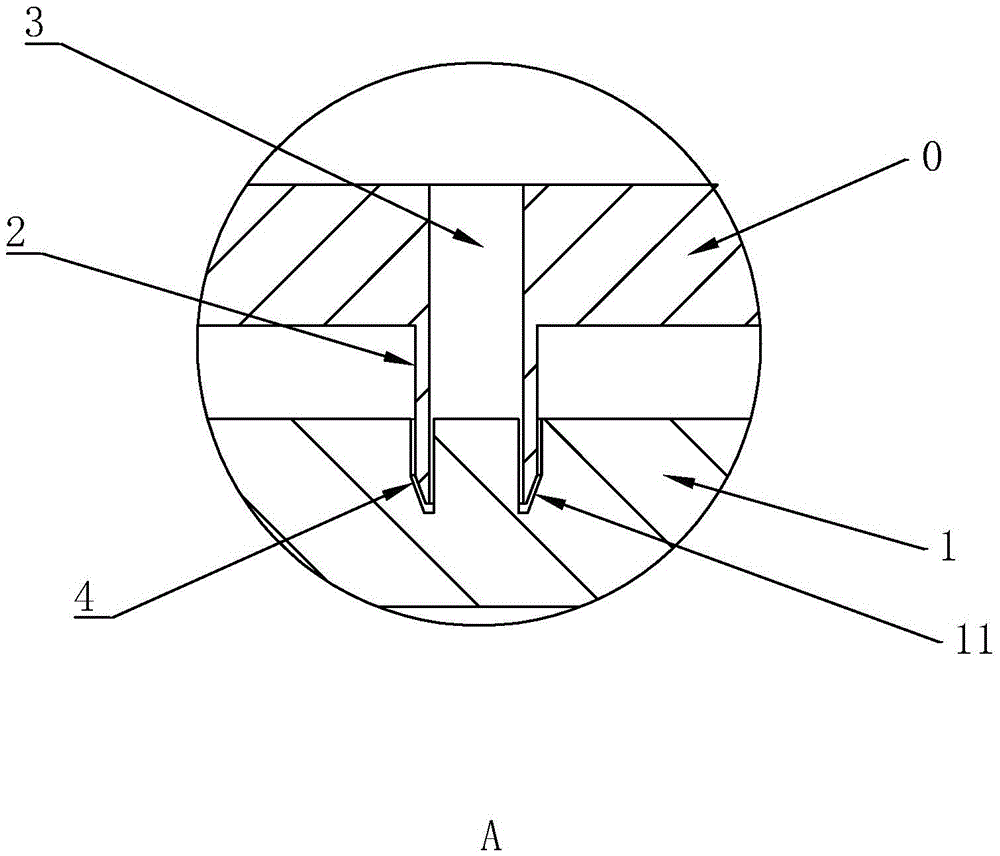

[0034] Attached to the following figure 1 to the attached image 3 The present invention will be described in further detail.

[0035] This specific embodiment is only an explanation of the present invention, and it is not a limitation of the present invention. Those skilled in the art can make modifications to the present embodiment without creative contribution as needed after reading this specification, but as long as the rights of the present invention are used All claims are protected by patent law.

[0036] like figure 1 and image 3 As shown, an electroplating jig for a rubber stopper includes an electrode plate 0, on which at least one flange 2 is formed that is matched with a mold cavity 11, and an electroplating jig is formed between the flange 2 and the mold cavity 11. The gap 4 for liquid flow, the flange 2 is provided with a through hole 3 passing through the electrode plate 0 along its own axis, and the flange 2 is suspended in the mold cavity 11. The matchi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com