Enhanced imbibition system of carbonated water under high temperature and high pressure conditions

A high temperature and high pressure, carbonized water technology, applied in the field of oil drilling engineering, can solve the problems that high temperature and high pressure cannot be simulated, the design does not conform to the actual formation conditions, and the viscosity of crude oil is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to further understand the content of the present invention, the present invention will be described in detail below in conjunction with specific examples.

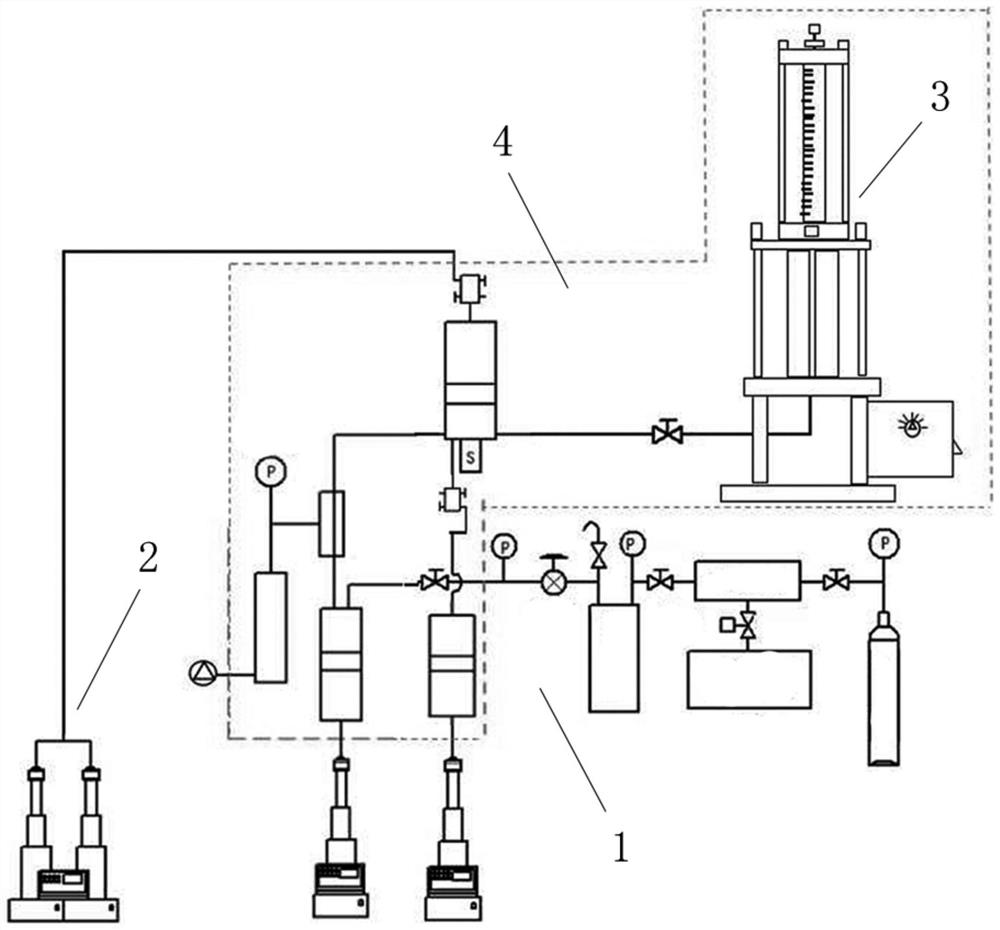

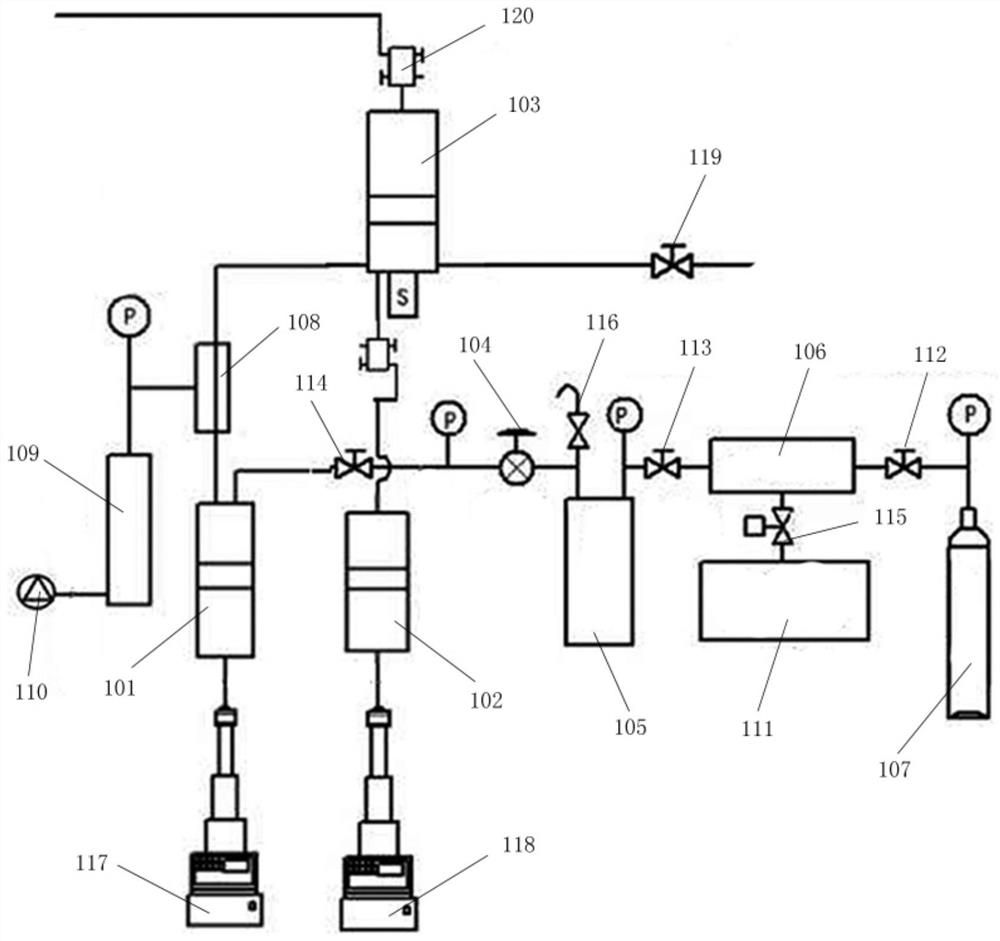

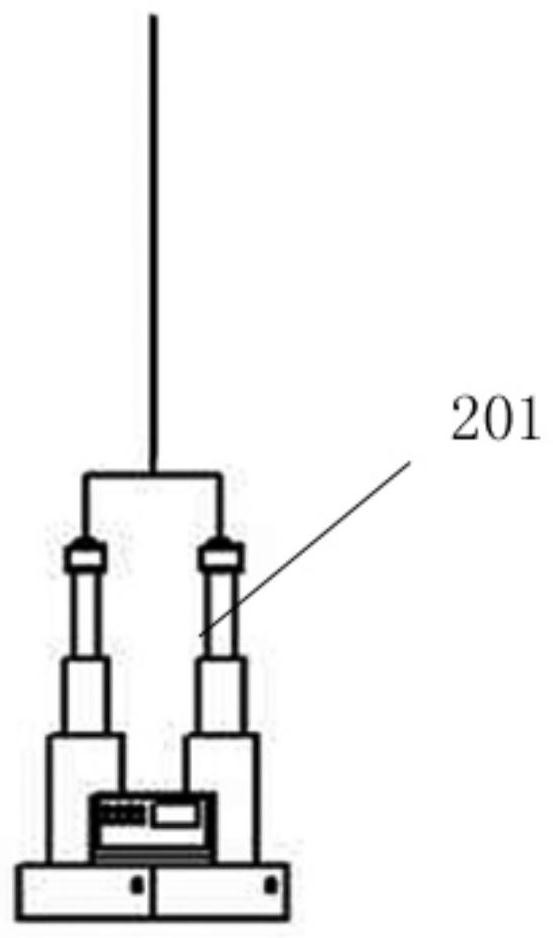

[0050] Such as Figure 1-5 Shown, according to an embodiment of the imbibition system of strengthening carbonized water under the high temperature and high pressure condition of the present invention, comprise the preparation system 1 of carbonated water, the injection system 2 of carbonated water and the imbibition system 3 of rock core, the osmosis system 3 of described carbonized water The preparation system 1 is connected with the imbibition system 3 of the rock core through a pipeline, and the injection system 2 of the carbonated water injects the carbonated water into the imbibition system 3 of the rock core; the carbonization in the imbibition system 3 of the rock core The water can rotate and flow, and the carbonized water is dissolved CO 2 of aqueous solution.

[0051] In this embodiment, carbonize...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com