Intelligent double-arm safety cooperation man-machine co-melting robot system

A robot system and dual-arm technology, applied in the field of human-computer interaction, can solve problems such as the incompetence of robots, and achieve the effects of hand-eye coordination positioning accuracy, fast speed, and simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

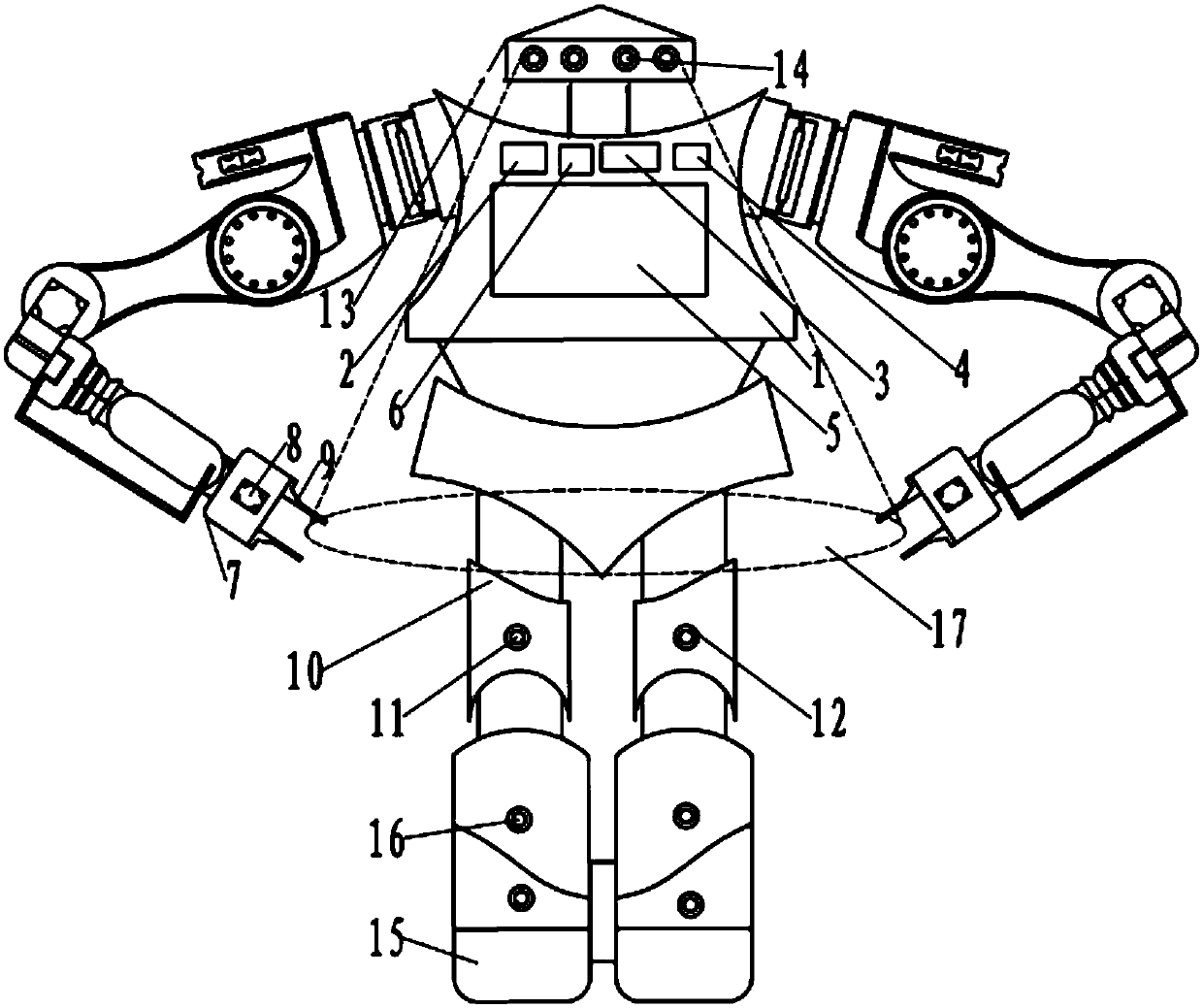

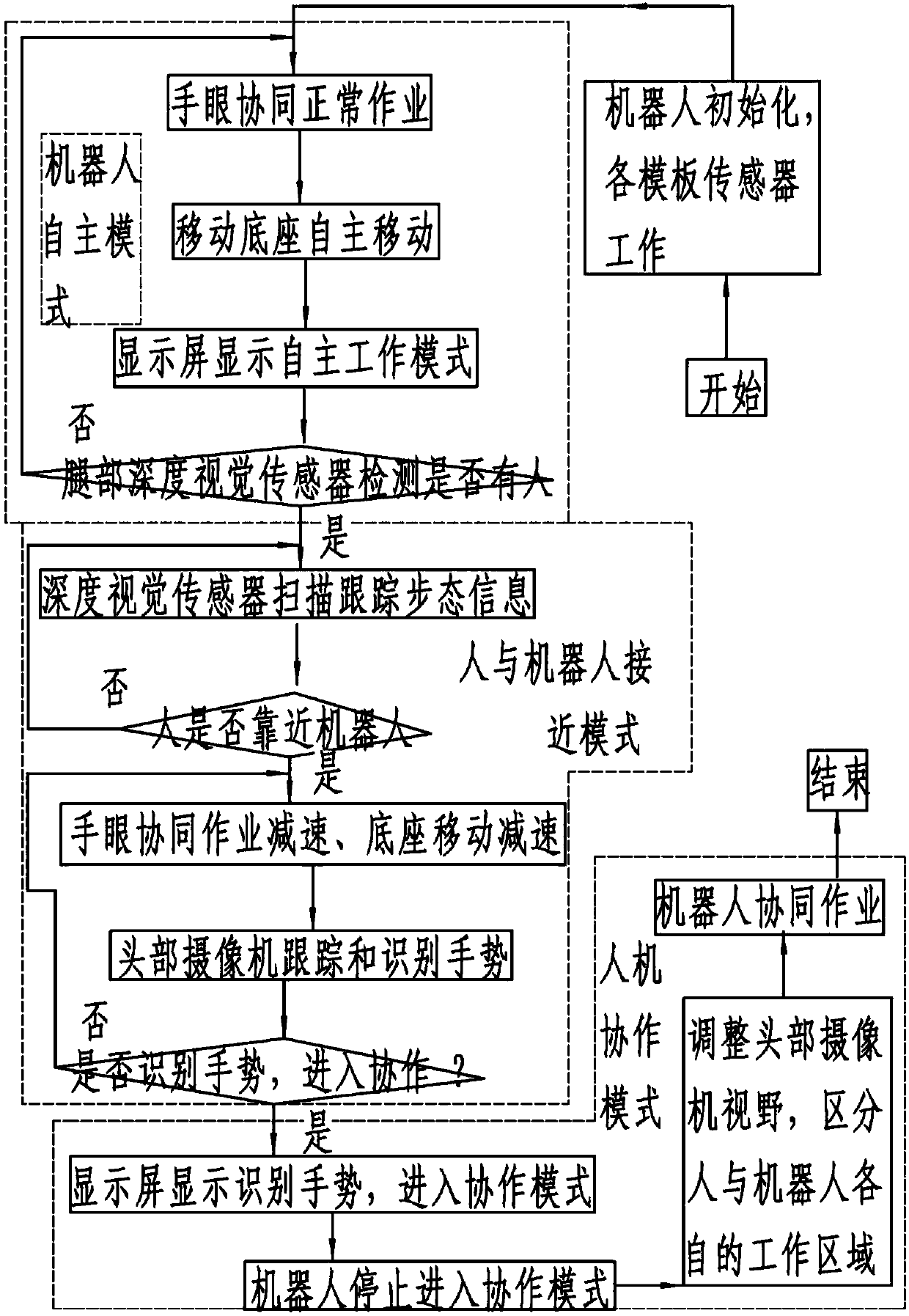

[0033] Such as figure 1As shown, the intelligent dual-arm safety cooperative human-machine fusion robot system of this embodiment includes a chest support 1 of the robot, a main board 3 installed on the chest support 1, a communication module 4 integrated on the main board 3, a hard disk, and a vision board And the total control processor 6, the interactive display screen 5 electrically connected with the total control processor 6, the controller electrically connected with the total control processor 6, the limbs connected with the chest support 1, arranged on the limbs and connected with the communication module 4 electrically connected depth vision sensors, the head 13 driven by more than two axes whose lower end is connected to the chest support 1, and the head 13 that is driven by more than two axes and is electrically connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com