Wind-assisted rotary cylinder with spiral side plate

A rotary drum and wind power technology is applied in the field of ship wind-assisted rotary drums, which can solve the problems of low wind energy conversion rate, large Magnus lift, and inability to generate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

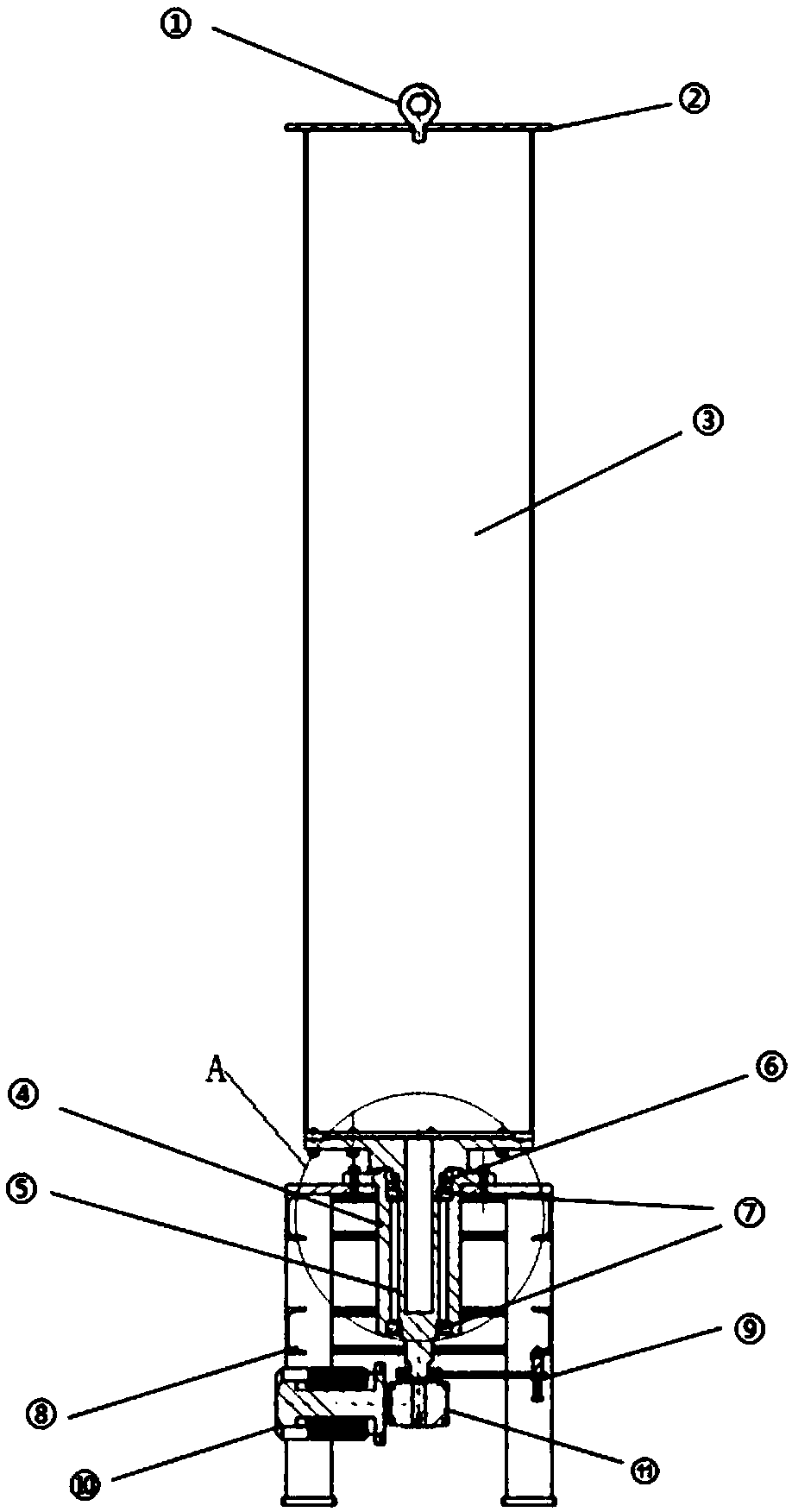

[0017] In order to make the marine wind-assisted navigation drum of the present invention easy to understand, it will be further elaborated below in conjunction with the accompanying drawings.

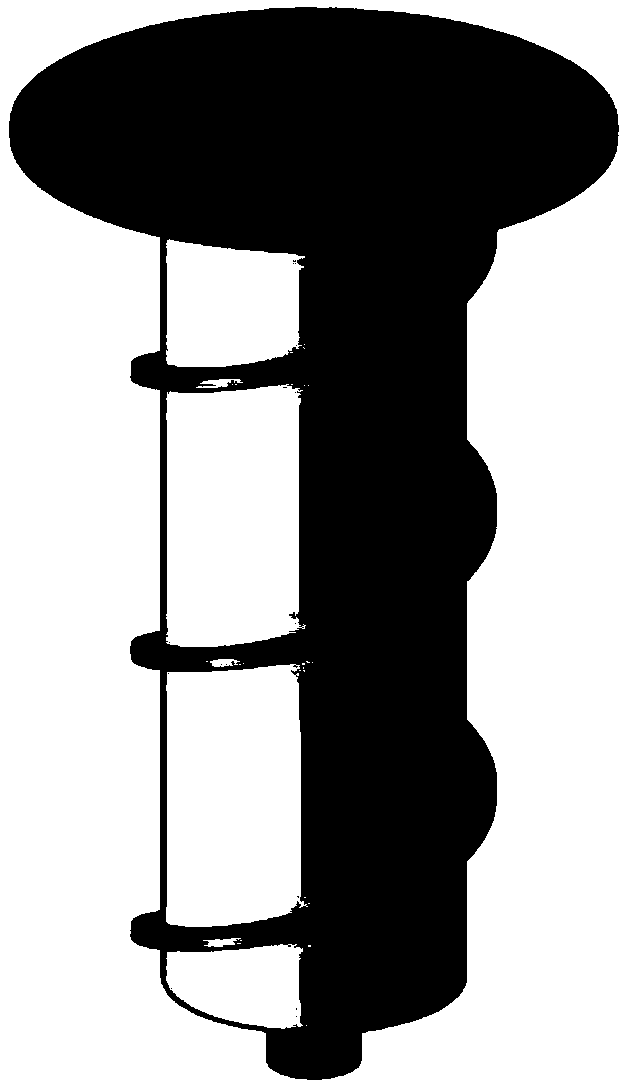

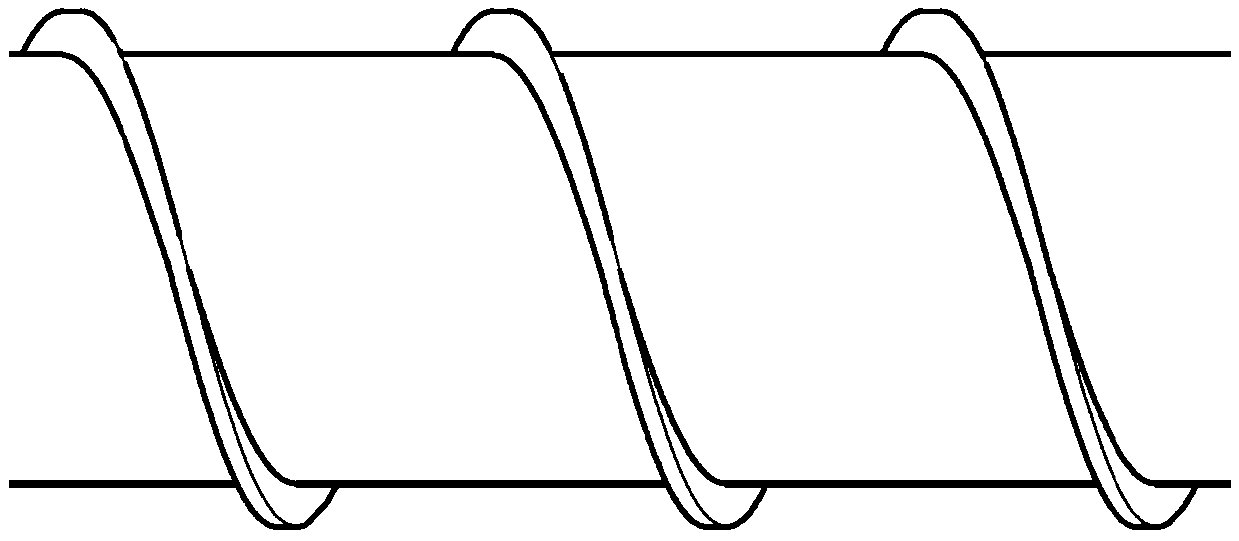

[0018] In the present invention, an air flow unit is arranged on the outer peripheral surface of the rotating cylinder 1 to increase the Magnus lift generated on the rotating cylinder 1 so as to achieve the purpose of reducing energy consumption.

[0019] The wind-assisted navigation drum of the present invention includes a rotating cylinder 1, a rotating cylinder driving motor 4, an air flow unit, an end plate 2, and a cylinder rotating shaft 5, and the end plate 2 is installed on the top of the rotating cylinder 1 , and is fixedly connected with the rotating cylinder 1 coaxially and with the center of the circle. The air flow unit is installed on the outer surface of the rotating cylinder 1. By generating air flow on the outer peripheral surface of the rotating cylinder 1, the Magnus ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com