Force Sensors for Surgical Devices

A force sensor, surgical technology, applied in measuring devices, surgical nails, instruments, etc., can solve problems such as premature failure, glass breakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Embodiments of the present disclosure will now be described in detail with reference to the accompanying drawings, wherein like reference numerals designate the same or corresponding elements throughout each of the several views. Throughout this description, the term "proximal end" refers to the portion of the device or its components that is closer to the user's hand, and the term "distal" refers to the portion of the device or its components that is further from the user's hand.

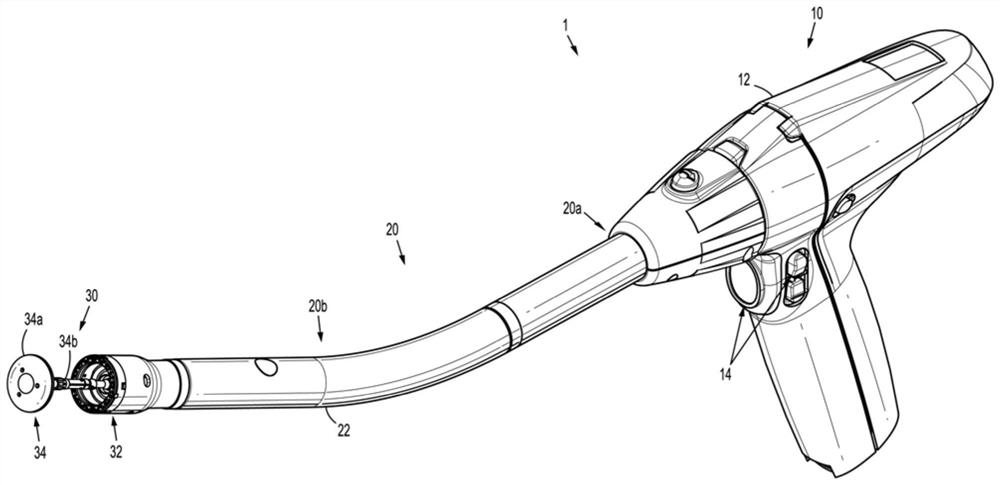

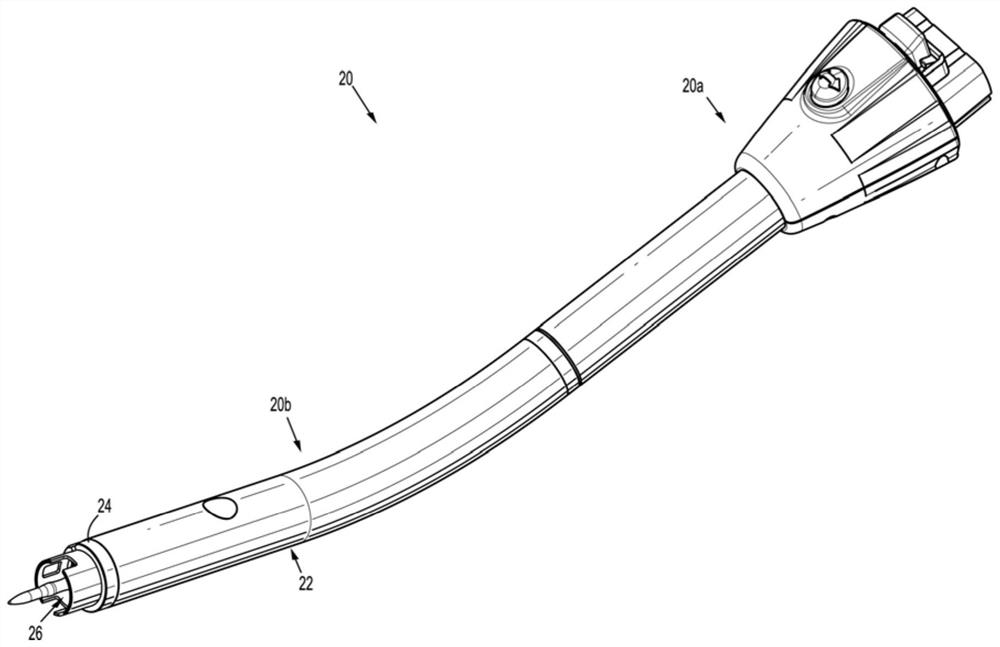

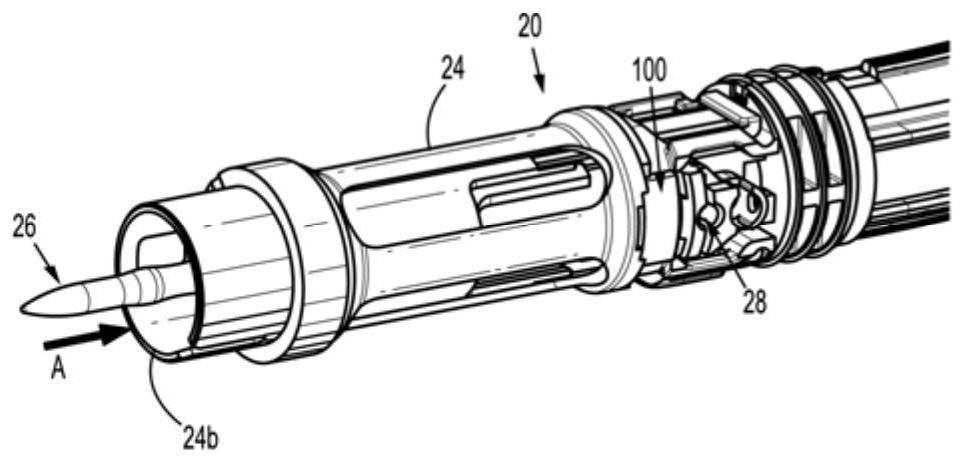

[0047] now go to figure 1 , the surgical device 1 according to embodiments of the present disclosure is in the form of a powered hand-held electromechanical instrument and includes a powered handle assembly 10, an adapter assembly 20, and a tool assembly or end effector 30, including a powered handle assembly 10, an adapter assembly 20, and a tool assembly or end effector 30. A loading unit 32 with a plurality of staples (not shown) therein and an anvil assembly 34 including an anvil head 34...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com