Intelligent pile driver for civil engineering

A technology for civil engineering and piling machine, which is applied in basic structure engineering, sheet pile wall, building and other directions, can solve the problems of low degree of intelligent control, uncontrollable piling depth, easy to skew piling, etc. Facilitate intelligent display and ensure the effect of piling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

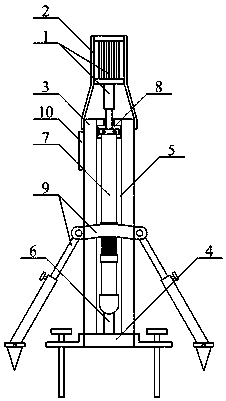

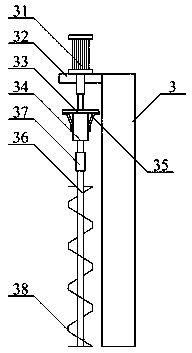

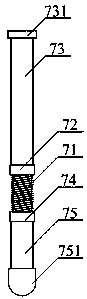

[0044] as attached figure 1 to attach Figure 6 shown

[0045] The invention provides an intelligent pile driver for civil engineering, which includes a primary cylinder 1, a fixed plate 2, a column 3, a rotating seat structure 4, a chute 5, a stainless steel slide rail 6, an adjustable pile structure 7, and a slider 8. The stable frame 9 and the intelligent control cabinet 10, the first-stage cylinder 1 is installed on the upper part of the front surface of the column 3 through the fixed plate 2 bolts arranged in pairs; the longitudinal lower end of the column 3 is installed on the rotating seat structure 4 The inner middle position of the chute 5 is set longitudinally in the middle position of the front surface of the column 3; the stainless steel slide rail 6 longitudinal bolts are installed in the inner middle position of the chute 5; the adjustable pile structure 7 Longitudinally placed on the front surface of the stainless steel slide rail 6; the upper end of the adjusta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com