Steel sleeve rotating-type locking mechanism

A locking mechanism and rotary technology, applied in the connection of connecting components, mechanical equipment, rods, etc., can solve the problems of inconvenient operation, uneven force, etc., to improve the connection speed and strength, uniform force, improve The effect of compression strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

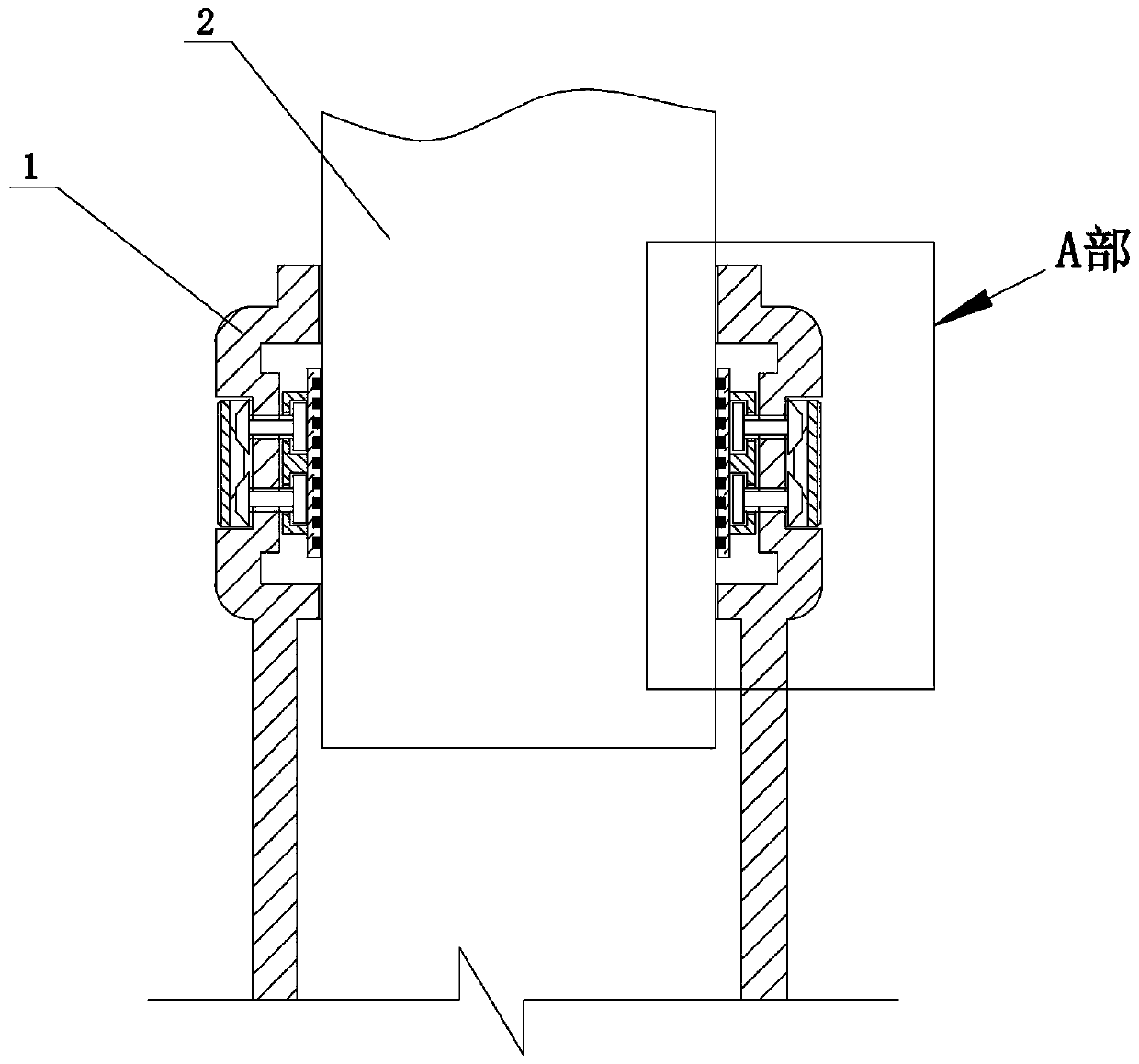

[0012] Embodiment 1: as figure 1 The steel casing rotary locking mechanism shown is located between the outer casing 1 and the inner casing 2 which are fitted together. An annular concave groove is arranged on the side wall of the outer sleeve 1 , and there are even a pair of adjusting and pressing components symmetrically on the inner wall 301 of the annular concave groove. Both sides adjust and hold down the assembly structure identically.

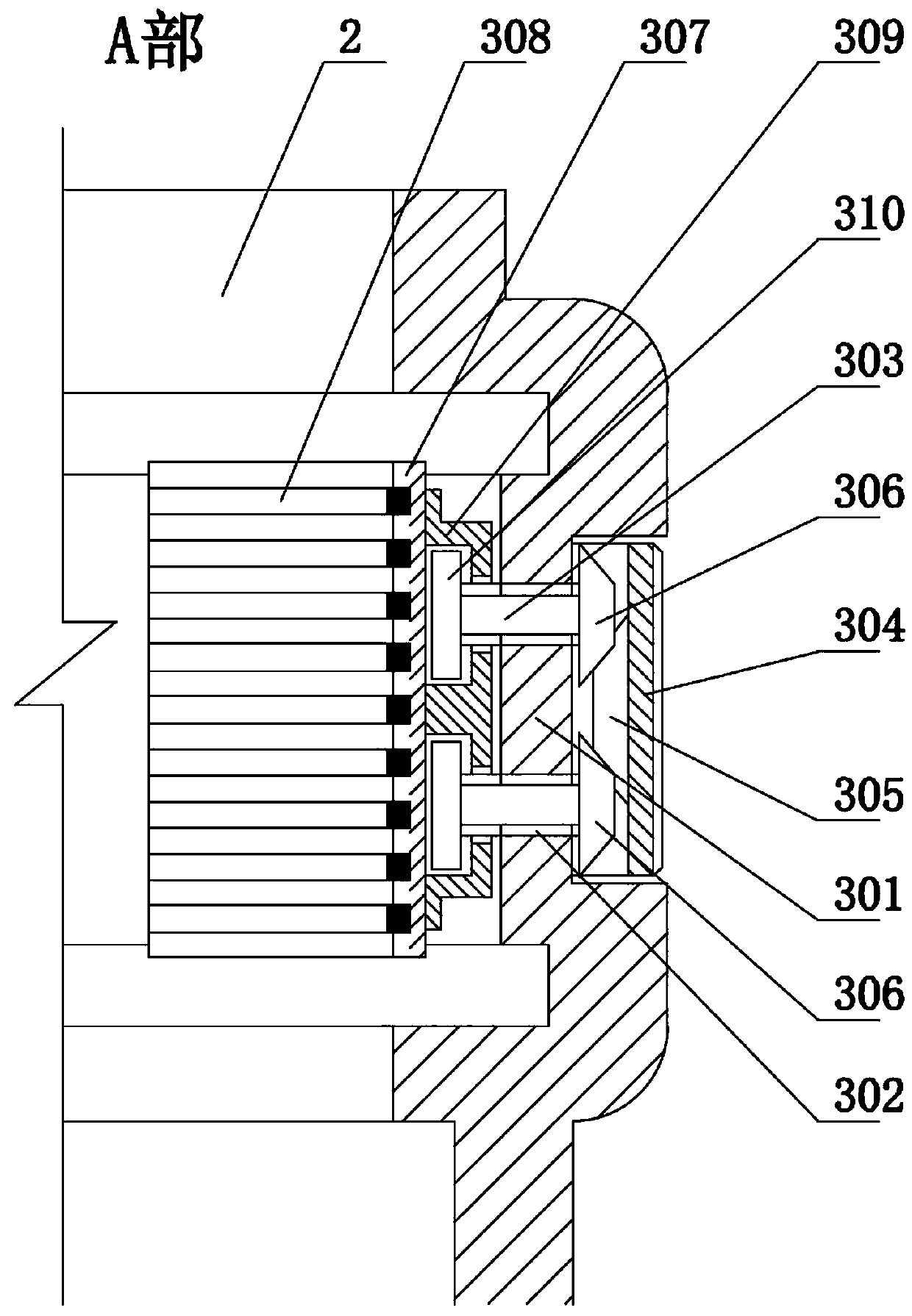

[0013] For the specific structure of adjusting the pressing assembly, see figure 2 As shown, it includes an arc-shaped pressing tile 307 matching the side of the inner casing 2 and a pair of adjusting bolts 303 with opposite thread directions. A pair of adjusting bolts 303 is movably connected with the back of the arc-shaped pressing tile 307 . A pair of screw holes 302 with opposite helical directions are formed on the inner wall 301 of the annular recess, and the pair of adjusting bolts 303 are matched and installed in the correspo...

Embodiment 2

[0019] Embodiment 2: On the basis of Embodiment 1, an adjusting ring 304 is set on the outside of the annular recessed groove, and the side wall of the outer sleeve 1 outside the annular recessed groove is provided with annular convex and concave moldings respectively on the inner wall of the adjusting ring 304, The side wall of the outer casing 1 and the inner wall of the adjustment ring 304 are embedded with each other by matching annular convex and concave moldings. And a gap is set between adjacent annular convex and concave fillets and a sealing ring is set. Improve the sealing performance to the adjustment parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com