Smashing device for regenerating base fertilizer through nursery stock waste branches

A technology for pulverizing device and waste branches, which is applied in mixers with rotary stirring devices, transportation and packaging, dissolving and other directions, can solve problems such as impact on the environment and waste of resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

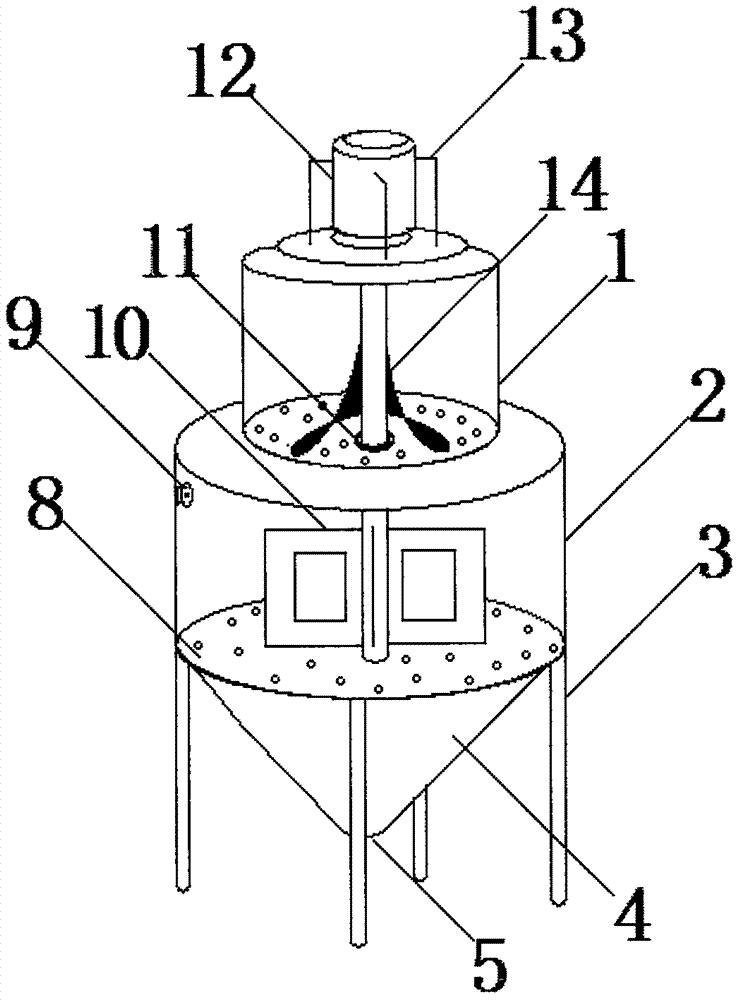

[0012] figure 1 Among them, the No. 2 unit is composed of a fine crushing bin 1, a mixing bin 2 and a lower material bin 4. A circular opening 7 is dug through the center of the upper surface of the fine crushing bin 1, and the upper side of the fine crushing bin 1 is set An interface 6, the lower side of the fine crushing bin 1 is welded to the upper surface of the corresponding mixing bin 2, and a round hole is dug on the upper side of the mixing bin 2, and a joint is arranged in the round hole, and the ring-shaped bottom of the mixing bin 2 The side edges are respectively evenly spaced and erected with four legs 3 , the outer edge of the bottom of the mixing bin 2 is welded to the upper edge of the lower bin 4 , and the lower port of the lower bin 4 is set as a discharge port 5 .

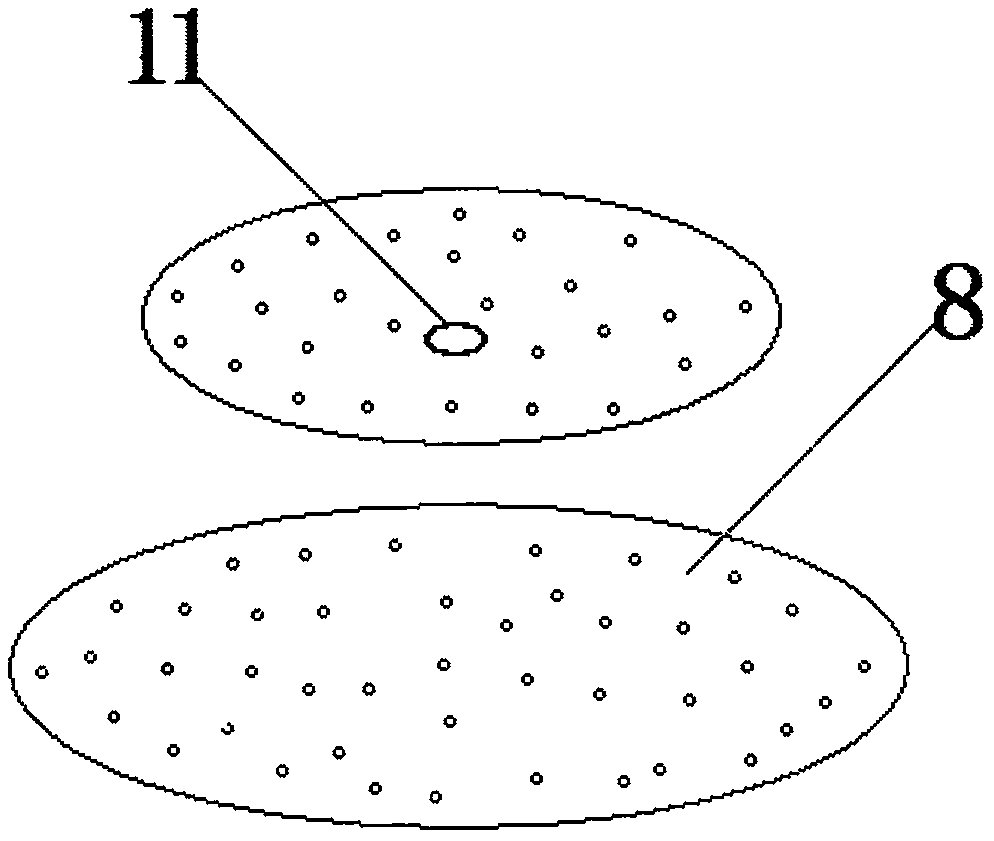

[0013] figure 2 include figure 1 , the lowermost part of the cavity of the fine c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com