Ridging machine

A technology for building ridges and racks, which is applied to agricultural machinery and implements, shovels, plows, etc., and can solve problems such as low operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

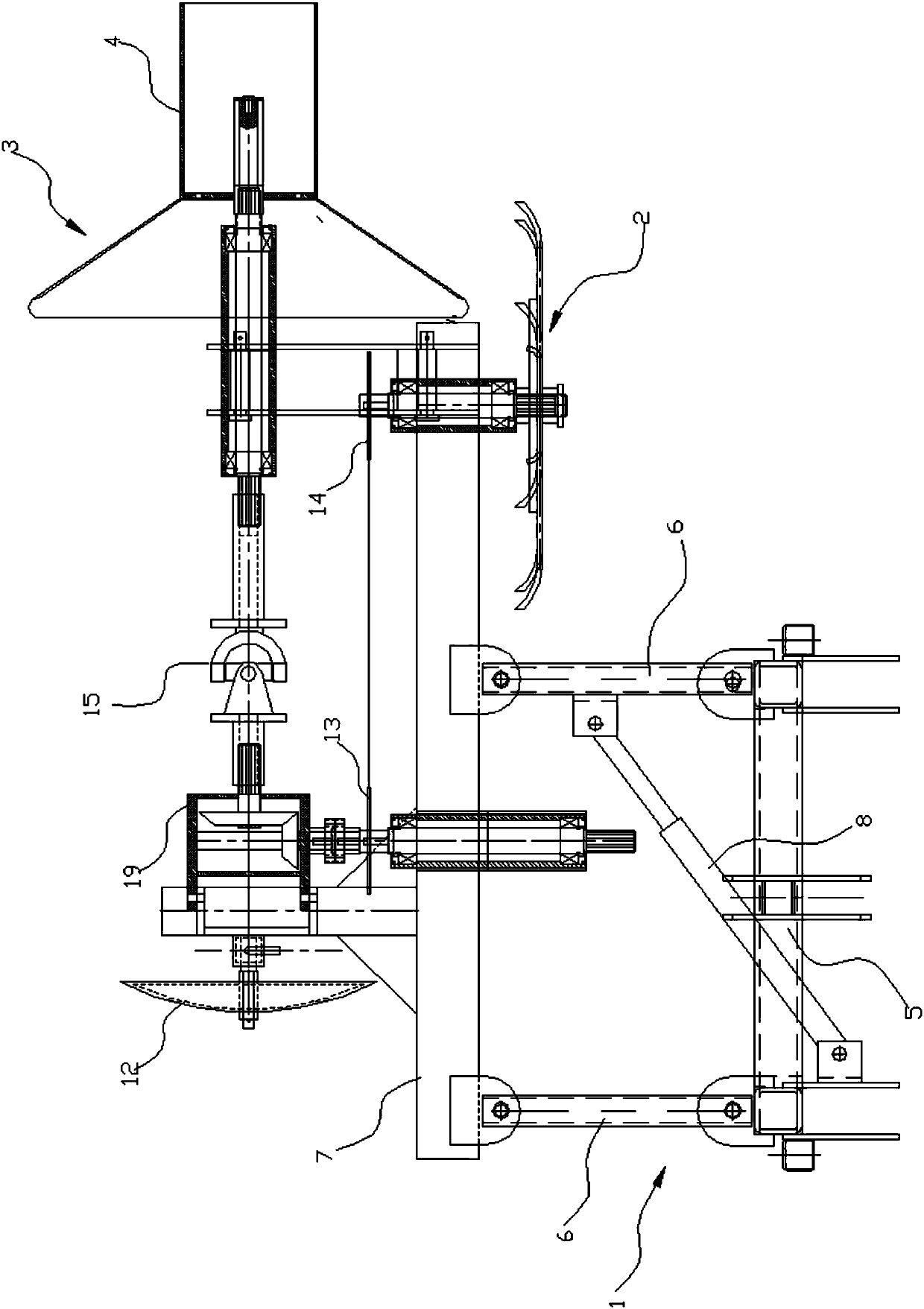

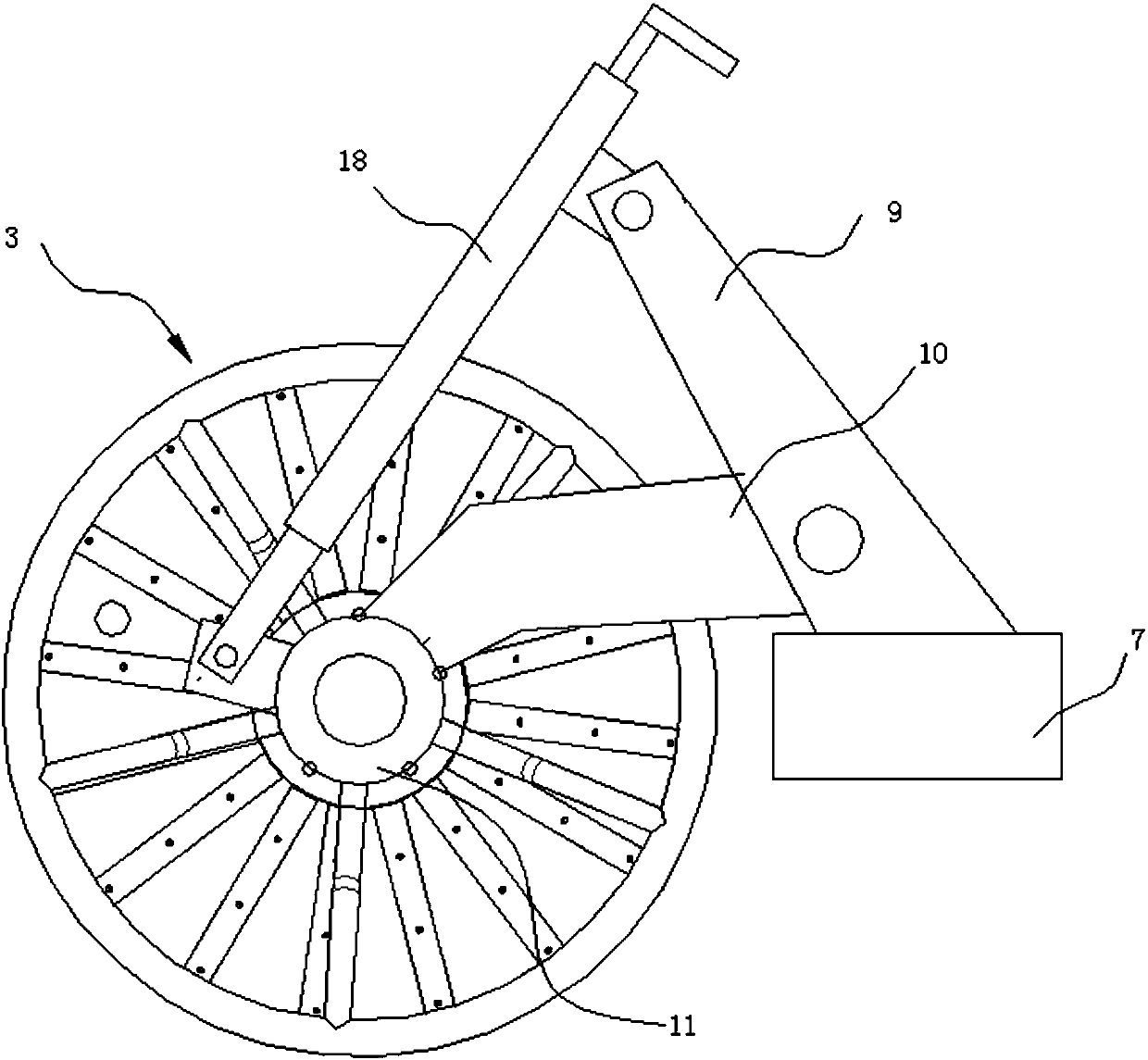

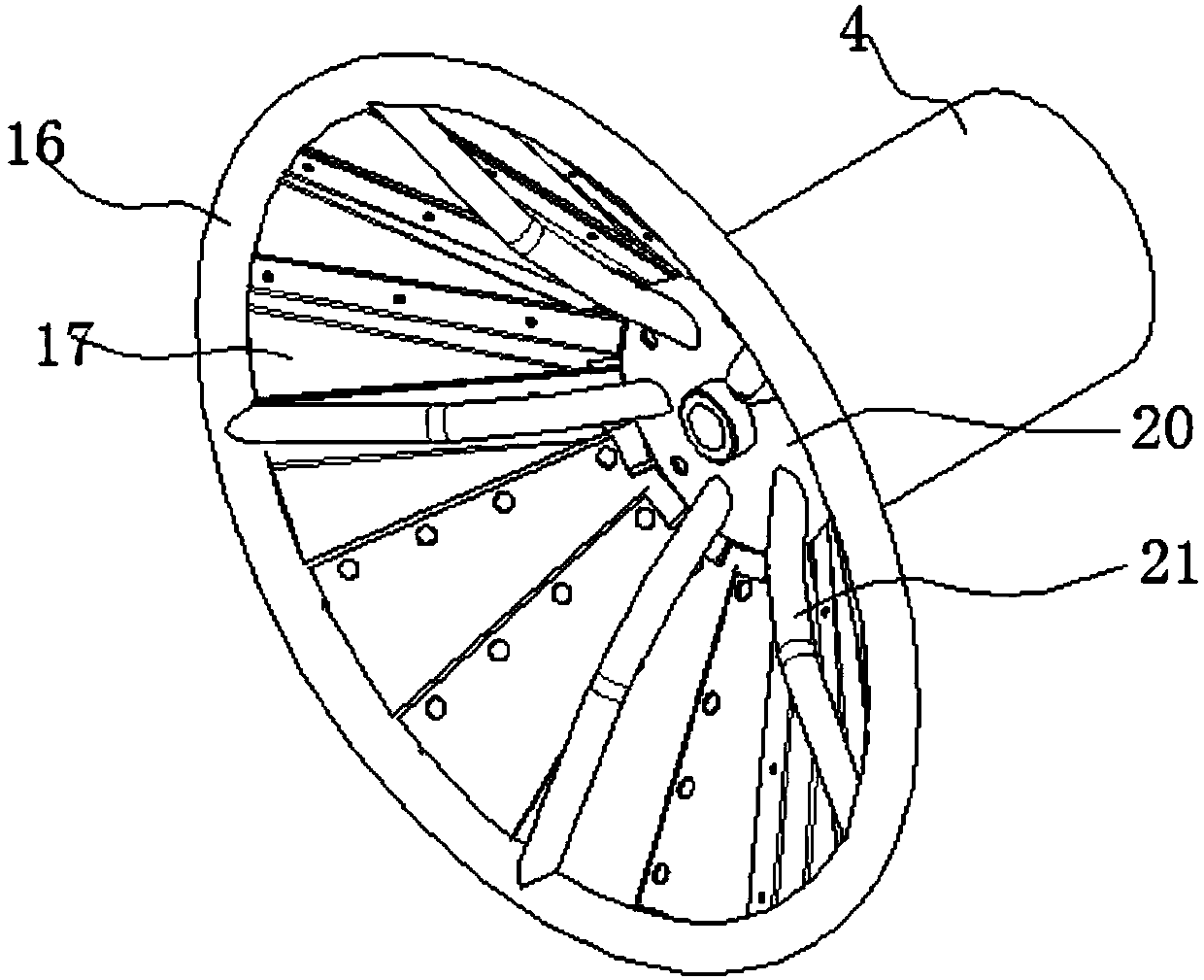

[0020] Such as figure 1 , image 3 and Figure 4 As shown, a ridge building machine includes a frame 1, on which the ridge working head is rotatably installed, and on the frame 1 is also rotatably installed with the ridge working head installed on the frame. The tiller knife 2 for turning the soil on one side, the ridge working head includes a tapered roller 3, the large end of the tapered roller 3 faces the soil tiller 2, and the small end of the tapered roller 3 is installed Cylindrical pressure roller 4 is arranged, and the driving device that drives described tillage knife 2 to rotate is installed on described frame 1; before the head. The soil tiller turns up the soil on the side where the ridge working head is installed on the frame, and the ridge working head builds ridges for the turned up soil, which changes the traditional plow plowing method and has the advantage of high ridge building efficiency. The tapered roller shapes the inclined surface of the ridge, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com