A kind of method for producing sapo molecular sieve

A molecular sieve and hydrothermal technology, applied in the direction of molecular sieve and alkali-exchanged phosphate, molecular sieve characteristic silicoaluminophosphate, etc., can solve the problems of difficult solid-liquid separation in the industrial production of SAPO molecular sieve, avoid clogging, improve separation speed, and treat volume increase effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

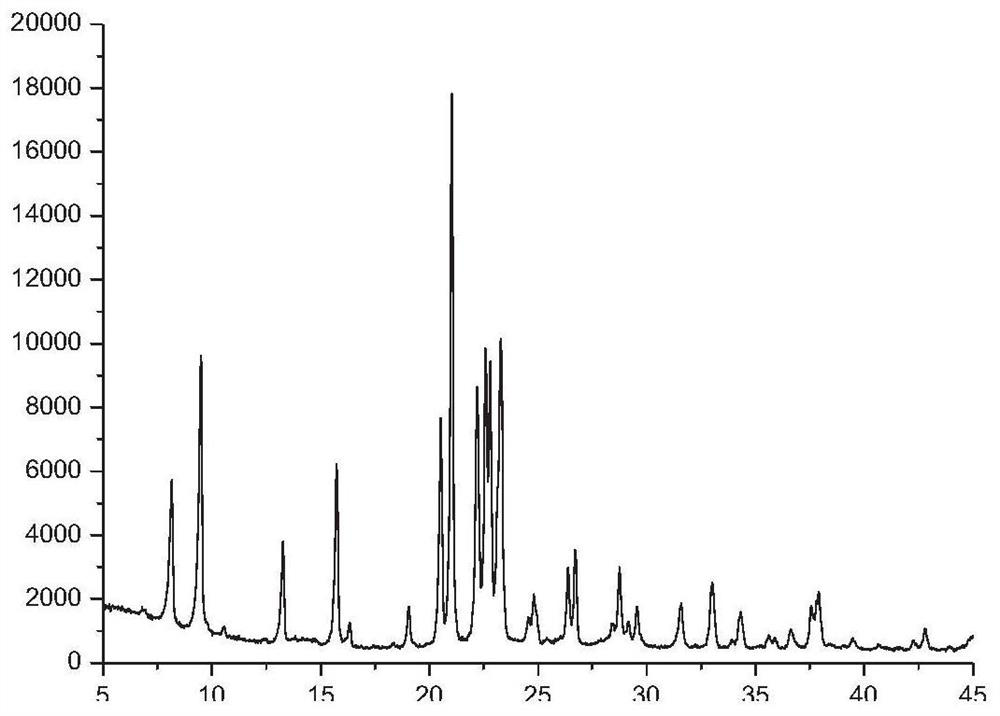

[0030] Weigh 500 g of industrially produced SAPO-11 molecular sieve crystallization solution, add 20 g of 30% phosphoric acid solution, mix and perform vacuum filtration at a rate of 40 g / min, and then wash with water for several times. The obtained solid is dried to obtain the raw powder of SAPO-11 molecular sieve. Characterized by XRD, the crystallinity is 98%.

Embodiment 2

[0032] Weigh 500 g of industrially produced SAPO-11 molecular sieve crystallization solution, add 20 g of 45% phosphoric acid solution, mix and perform vacuum filtration at a rate of 70 g / min, and then wash with water for several times. The obtained solid is dried to obtain the raw powder of SAPO-11 molecular sieve. Characterized by XRD, the crystallinity is 96%.

Embodiment 3

[0034] Weigh 500 g of industrially produced SAPO-11 molecular sieve crystallization solution, add 30 g of 55% phosphoric acid solution, mix and perform vacuum filtration at a rate of 75 g / min, and then wash with water for several times. The obtained solid is dried to obtain the original SAPO-11 molecular sieve powder. Characterized by XRD, the crystallinity is 96%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com