A decolorizing solution for protecting peanut polysaccharide and its preparation method

A technology for decolorizing liquid and polysaccharide, applied in chemical instruments and methods, other chemical processes and other directions, can solve the problems of decreased peanut polysaccharide content, destruction of peanut polysaccharide, loss of peanut polysaccharide, etc., and achieves simple use method, simple preparation method and high application. effect of value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

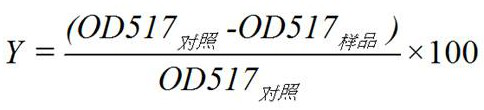

Image

Examples

Embodiment 1

[0030] This embodiment provides a decolorizing solution and a preparation method for protecting peanut polysaccharides. The preparation method of the decolorizing solution is as follows:

[0031] 1. Grinding of activated carbon: select DS-305 activated carbon for sugar, put it in a traditional Chinese medicine grinder for pulverization, pass through a 40-mesh sieve after pulverization, and obtain activated carbon powder for sugar;

[0032] 2. Peanut shell crushing: put the peanut shell in a blast drying oven to dry until the moisture content is less than 6%, put it in a traditional Chinese medicine grinder after drying, and pass through a 40-mesh sieve to obtain peanut shell powder;

[0033] 3. Soaking in hydrochloric acid aqueous solution: Soak peanut shell powder in 3mol / L hydrochloric acid aqueous solution for 100min to obtain mixed solution Ⅰ;

[0034] 4. Centrifugation: Centrifuge the mixed solution I treated with aqueous hydrochloric acid solution at 6000r / min for 20 min...

Embodiment 2

[0041] This embodiment provides a decolorizing solution and a preparation method for protecting peanut polysaccharides. The preparation method of the decolorizing solution is as follows:

[0042] 1. Grinding of activated carbon: select DS-305 activated carbon for sugar, put it in a traditional Chinese medicine grinder for pulverization, pass through a 100-mesh sieve after pulverization, and obtain activated carbon powder for sugar;

[0043] 2. Peanut shell crushing: Put the peanut shells in a blast drying oven to dry until the water content is less than 7%, put them in a traditional Chinese medicine grinder after drying, and pass through a 100-mesh sieve to obtain peanut shell powder;

[0044] 3. Soaking in hydrochloric acid aqueous solution: Soak peanut shell powder in 1mol / L hydrochloric acid aqueous solution for 20 minutes to obtain mixed solution Ⅰ;

[0045] 4. Centrifugation: Centrifuge the mixed solution I treated with hydrochloric acid aqueous solution at 5000r / min for ...

Embodiment 3

[0052] This embodiment provides a decolorizing solution and a preparation method for protecting peanut polysaccharides. The preparation method of the decolorizing solution is as follows:

[0053] 1. Grinding of activated carbon: select DS-305 activated carbon for sugar, put it in a traditional Chinese medicine grinder for pulverization, pass through a 60-mesh sieve after pulverization, and obtain activated carbon powder for sugar;

[0054] 2. Peanut shell crushing: Put the peanut shell in a blast drying oven to dry until the water content is less than 8%, put it in a traditional Chinese medicine grinder after drying, and pass through a 60-mesh sieve to obtain peanut shell powder;

[0055] 3. Soaking in hydrochloric acid aqueous solution: Soak peanut shell powder in 5mol / L hydrochloric acid aqueous solution for 180min to obtain mixed solution Ⅰ;

[0056] 4. Centrifugation: Centrifuge the mixed solution I treated with aqueous hydrochloric acid solution at 8000r / min for 30 minute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com